What tests do I need to do before putting a marine hose back into service after a period of storage?

What do you do with hoses when they are removed from operations?

Furthermore, for those hoses that are no longer suitable for their initial purpose, it may be possible to recycle and repurposethe hose to perform a suction or discharge role with non-pollutant fluid. For example, a hose could perform a dredging function or act as a dirty water pipe.

Another option is to repurpose a hose as a protection device. This can include removing the flange to be utilised as a dock fender. Recycling and repurposing an old hose can limit the impact that the hose has on the environment, and help reduce operating costs. Do not hesitate to contact us for further solutions on hose recycling and repurposing.

What should you consider when selecting a Seawater intake hose?

The challenging market environment we have seen over the last few years has led to increasing interest in new solutions as operations look to reduce capital expenditure. These new solutions include an increased attention to hybrid seawater intake risers using a combination of HDPE plastic pipes and rubber hose technology. While these hybrid solutions using plastic pipes can offer capital cost savings in the region of 20-30%, they also pose challenges that impact on operability, reliability and efficiency.

These challenges stem from the properties of HDPE itself. HDPE floats when submerged in water, and thus a HDPE riser must be weighted down to make sure that there is a consistent intake of water and that strainer is at the lowest possible depth. Ballast weighting is also required for stabilising purposes. All of this puts a huge amount of stress on the riser, increasing the risk of failure and creating a lot more risk to both the vessel and seabed assets.

Alongside the risk, the operational concerns pose a serious problem – particularly for FLNG operations. Liquefaction processes expel a lot of heat, and colder water makes it possible to produce LNG more efficiently and more safely. The natural buoyancy, relative fragility and increased pressure on a hybrid riser means that the seawater collected is from a shallower depth – when temperatures rise quickly as you get closer to the surface, significantly impacting the efficiency of the operation.

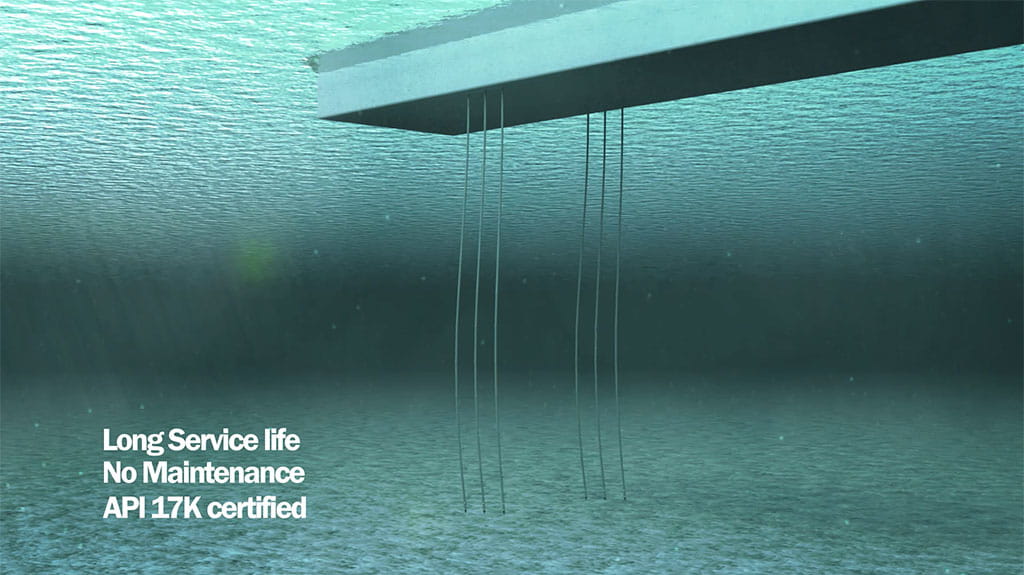

In 2016, Trelleborg’s oil and marine operation launched its dedicated seawater intake hose solution to fix these problems, which once again pushed the boundaries of technology in the oil and gas sector. Our Swiline hoses are fully certified to the API Spec 17K standard, which certifies up to 30 years’ maintenance free service life.

Swiline hoses are designed to be used in lengths of up to 600 meters or even more, enabling the use of seawater from greater depths, which can be up to 20 ºC / 68 ºF cooler than water at the surface. Hybrid systems, on the other hand, will operate in much shallower depths, resulting in warmer water being used during the liquefaction process.

Employing a unique design incorporating an integrated bending stiffener with a continuous inner liner and rubber outer cover, the hoses minimize the risk of corrosion while offering optimal thermal insulation. The combination of steel cables in a rubber matrix minimizes creep and offers typical tensile strength as high as 1,600 tonnes for 40-inch internal diameter hose– a key attribute when the higher weights required to maintain the position of the hose in high currents are considered.

Swiline hoses can be easily installed vertically from the FPSO or FLNG deck. Assembly can take place beside the hull with connection on the intake flange by divers, or in the riser caisson with need of diver during installation.