GOLDLINE® PREMIUM 38

High abrasion resistant pre-cured natural rubber sheet for rubber lining

High abrasion resistant pre-cured natural rubber sheet for rubber lining

Historically, rubber compounds have been ranked, specified and selected based on a wet version of the ISO 4649 dry abrasion test method. The SETAT test cell developed by Trelleborg Mining goes much further in its rubber testing regime to provide a new ranking of rubber compounds in terms of rubber loss.

- SETAT rubber test specimens and coupons are fully immersed during the test.

- SETAT cell can be heated to various temperatures to reflect actual slurry and operating conditions.

- SETAT test duration is significantly longer than ISO 4649. Rubber specimen contact with the selected test abradant can run up to 8,000 metres.

- SETAT test forces applied to the rubber specimen can be adjusted to reflect in-plant forces that rubber lined surfaces are subjected.

- SETAT test cell velocities can be varied.

- SETAT testing can be conducted at a range of abradant roughness’ to assess rubber loss under a range of wet fine and wet coarse conditions.

Trelleborg’s GoldLine® Premium 38 outranks other premium natural rubber sheet compounds under a range of SETAT test conditions and expect that this new test method will yield far greater insights for engineers involved in the specification and selection of premium rubber compounds needed to resist wet abrasion in mineral processing circuits.

For further SETAT test programme information please complete and submit the contact form below.

A well-balanced sheet rubber formulation and compound designed and developed by Trelleborg to deliver an optimum set of physical and mechanical properties needed to resist wear in wet abrasive environments and applications.

- High tensile strength.

- High elongation at break.

- High tear strength.

- High resilience.

- High abrasion resistance.

- Great flexibility.

- Dampens noise and vibration.

Wet abrasive duty applications ranging from -40 to +80˚C such as:

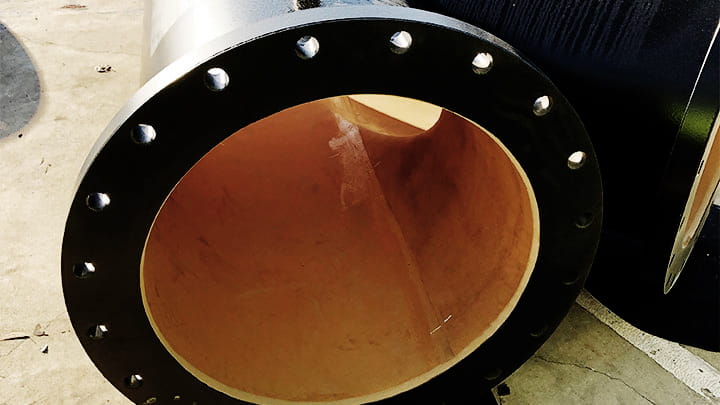

- Slurry pipe spools.

- Cyclones and clusters.

- Chutes.

- Hoppers.

- Launders.

- Tanks.

- Vessels,

- Mineral scrubbing and washing equipment.

- Flotation tanks and equipment.

- Agitator shafts and blades.

- Trommel frames.

- Screen underflow and oversize chutes.

- Mill and scrubber discharge aprons.

- Thickeners, rake arms and feed wells.

- Paste fill plants.

- Mine tailings.

- Gold lustre and colour.

- Enhanced submerged elevated temperature abrasion properties (SETAT).

- Very high natural rubber content.

- Soft and flexible.

- Wide roll formats up to 1.5 metre (W).

- 13 metre long rolls.

- Available in a range of thicknesses.

- Available in buffed or bonding layer finishes

- Improves equipment and asset reliability operating in arduous wet abrasive applications.

- Reduces downtime and maintenance costs.

- Easy application to steel surfaces using Trelleborg’s contact adhesives.

- Minimal full roll yield losses when lining 6 metre long pipe spools.

- One (1) single skive joint for lining 450 NB pipe spools.

- Excellent workability and flexibility for rubber lining under tension and compression.

- Dampens noise and vibration.

- Mining and mineral processing.

- Mineral sand dredging and processing.

- Gravel and quarrying.

- Cement and concrete.