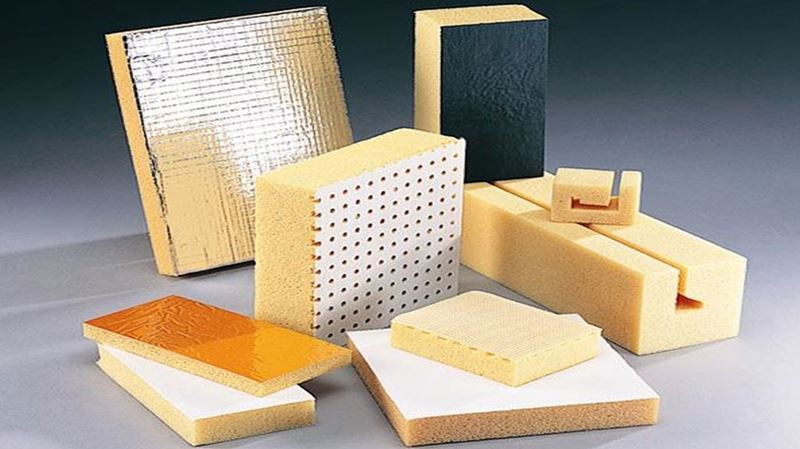

Confor® Cushioning and Impact Absorbing product sheet

Tufcote Barriers and Composites product sheet

Isodamp and Isoloss damping and isolating material product sheet

Isodamp and Isoloss grommets mounts and isolators product sheet

Isoloss LS energy control foam product sheet

Eccofloat® product sheet

Njord EB and Njord SB product sheet

Njord EB ellipsoidal buoyancy and Njord SB spherical buoyancy

Njord NB product sheet

Defense applications air

Defense applications helicopter

Defense applications land soldier

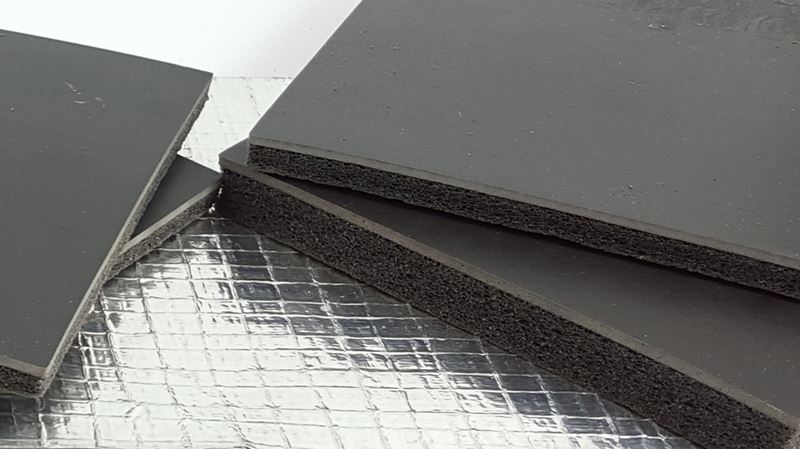

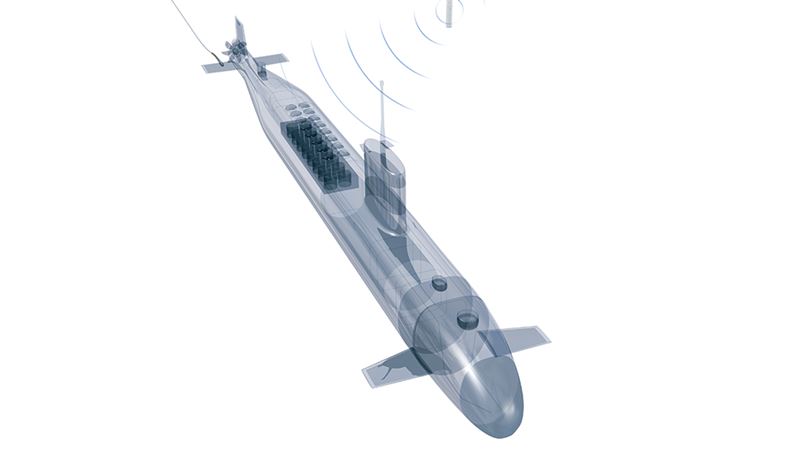

Defense applications subsea

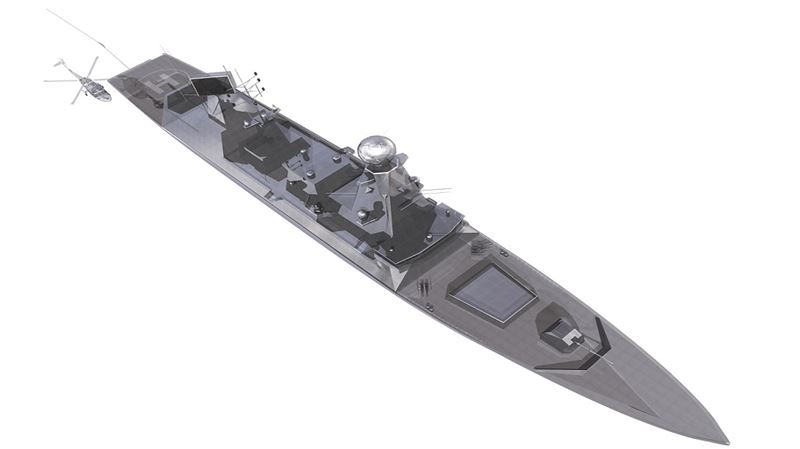

Defense applications surface

End of line Testing brochure

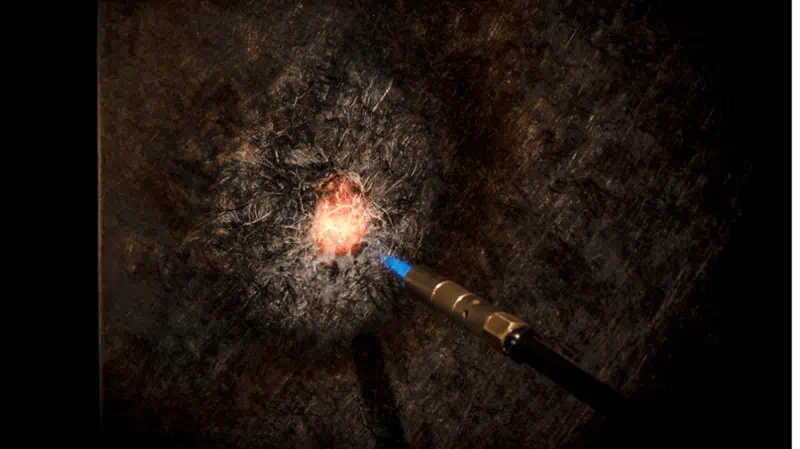

Erosion and abrasion protection material product sheet

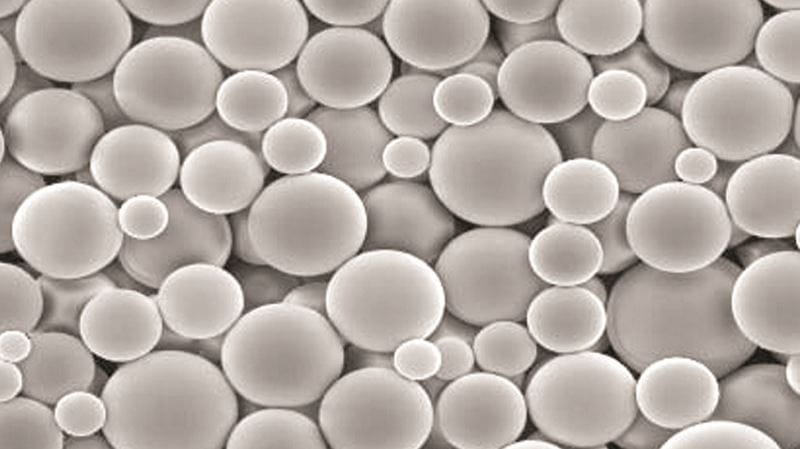

Eccospheres

Hollow shells aerospace

Hollow shells defense

Hollow shells medical

Hollow shells power plant

FR1500

FRV

Dryfoam

Leniter acoustic barrier system product sheet

Leniter ballast mat product sheet

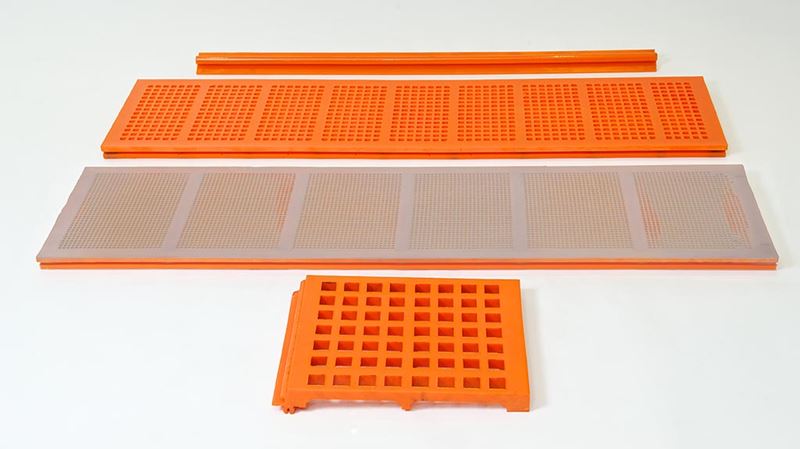

Pre coated rail system product sheet

Vector embedded rail system product sheet

Scandura brochure

Scandura datasheet

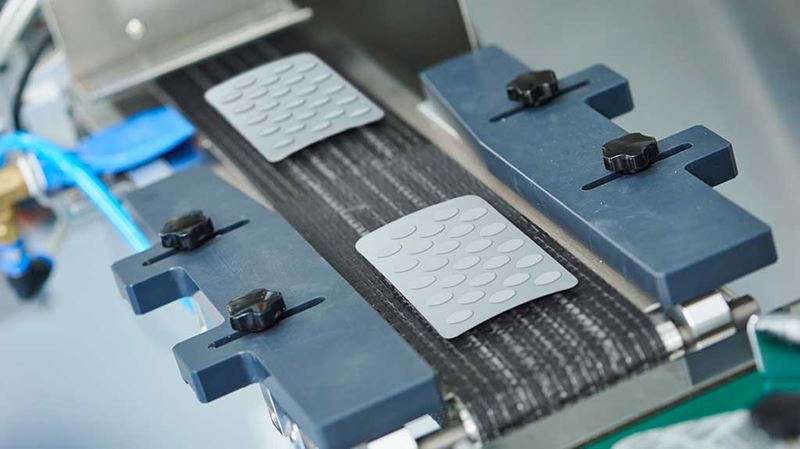

Unitex® Sprint

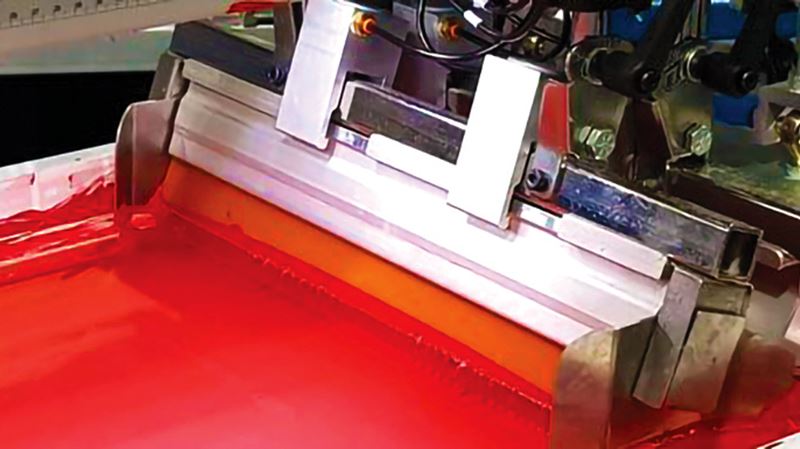

Unitex® Sprint provides premium screen-printing performance and quality at a competitive price.

Made from Diphenylmethane Diisocyanate (MDI) technology, Unitex® Sprint is designed to give high resistance to degradation by commonly used inks, solvents and monomers used in modern printing processes.

Unitex® Marathon

Unitex® Marathon provides premium screen printing performance and quality at a competitive price.

Made from high grade Diphenylmethane Diisocyanate (MDI) polyurethane, Unitex® Marathon is compatible with a wide range of graphic screen printing systems, designed to give superior resistance to degradation by commonly used inks, solvents and monomers used in modern printing processes.

Unitex® Exar

Unitex® Exar provides excellent screen printing performance for a wide range of applications.

Made from a high grade Diphenylmethane Diisocyanate (MDI) polyurethane Unitex® Exar is designed to provide exceptional abrasion resistance, ensuring consistent sharp image quality over long print runs. Independent tests showed a 69% improvement in abrasion loss against a standard MDI polyurethane, which translates to longer screen printing cycles. This will provide a significant cost and time savings as the blade does not need to be changed as often.

Unitex Ulon HP

Unitex® Ulon HP squeegee range provides optimum performance for the most demanding screen print applications. Manufactured from (Naphthalene Diisocyanate) (NDI) polyurethane technology, which provides a high of chemical and abrasion resistance, even when exposed to chemical systems. Unitex® Ulon HP is widely recognized as the best squeegee for use with solvent and UV based inks.

Unitex Range Brochure

Unitex Independent Report

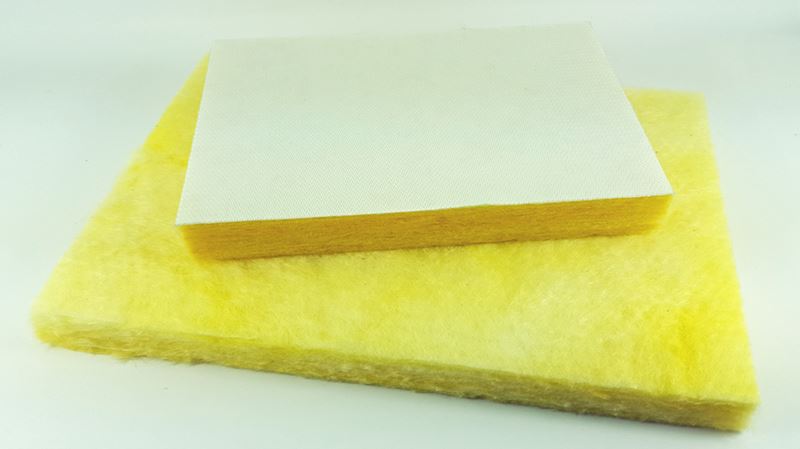

Intek® MTI 1046 fibre hull board insulation product sheet

Intek PFI 1110 product sheet

Intek PFI 1120 product sheet

Intek PFI 1130 product sheet

Intel UMI 1075 glass wool hull board insulation product sheet

Syntac 350

Syntac 450

Syntac HTS TDS

Syntac STS TDS

Syntac STS Features Article

EP678 epoxy tooling board