Creating small, intricate or large, complex designs can be challenging with a block tooling board system, often requiring a large amount of preparation and finishing to achieve the desired tool. Traditional epoxy tooling board materials require CNC machining to cut the blocks into the required pattern from a 3-D CAD image.

TC350 is an innovative castable epoxy tooling material, that can be used to create parts of any shape and size without using a CNC machine, as well as being available as a board system. Dimensionally stable in an autoclave at up to +180 °C, TC350 can be used to create multiple parts directly from the tooling. It maintains its shape at high temperatures, providing excellent toughness and durability.

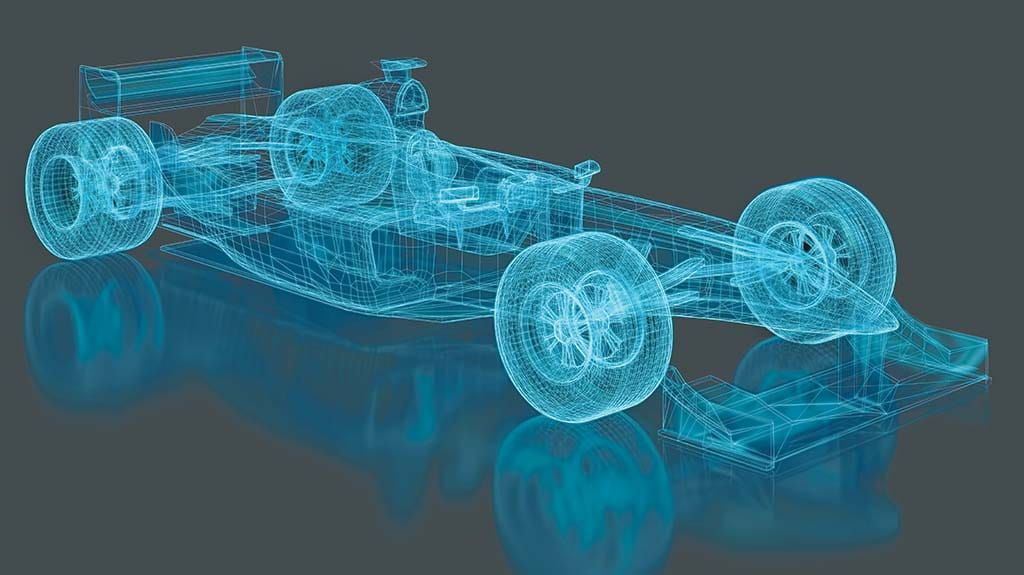

Engineered to support the creation of parts for use in extreme temperature environments such as aircraft manufacturing, TC350 is also suitable for use in electronic applications and is compatible with newer lightweight materials used in electric vehicle manufacturing. Carbon fiber, polypropylene and glass fibre reinforced plastics (GFRP) materials have a high-quality finish when produced using TC350.

Suitable for operation temperature use up to +180°C

Multiple finished parts can be made direct from the tooling

Available as a castable or board system

No requirement for CNC machining

Supports the manufacture of lightweight materials for electric vehicle production

Parts can be used for extreme temperature processes

Consistent, reliable performance

Can be cast to any shape required

Excellent toughness and durability

Direct to part tooling

High temperature curing for extreme temperature environments

Master models

Components for electronic applications