Isodamp and Isoloss foams offer practical, effective solutions to mitigate impact noise and structure-borne vibration in lightweight precision equipment frames, and reduce hydrodynamic vibrations in ship hulls.

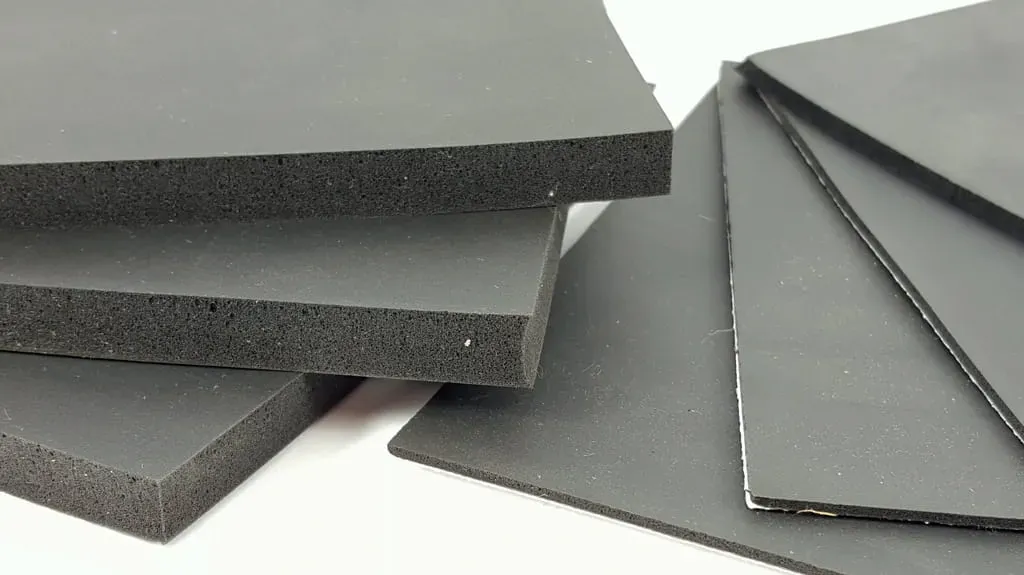

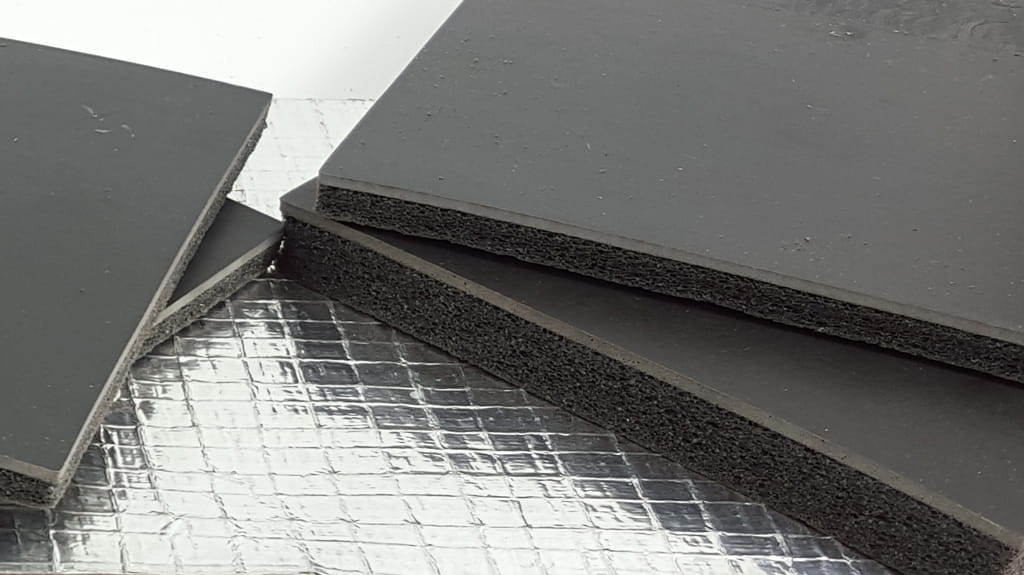

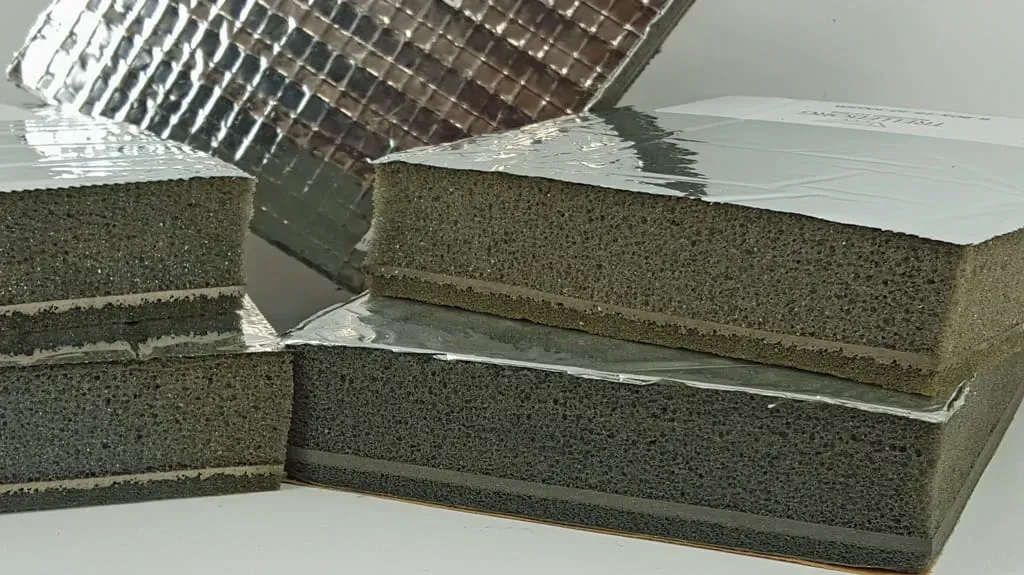

Available in a variety of forms:- sheets, rolls, die-cut, and custom molded parts. Isodamp vinyl foam material, and Isoloss urethane foam material achieves high-performance vibration control under diverse physical, temperature, and environmental conditions.

Isodamp and Isoloss are low weight materials that provide maximum performance, they have excellent flame-resistant properties, with specific styles meeting UL 94, V-O, FAR, ATS and QPL MIL specifications.

Supplied with a pressure-sensitive adhesive backing, Isodamp and Isoloss are available in sheet or die-cut form, with a wide range of thickness and temperature regimes available.

Designed to rapidly dissipate shock energy and reduce vibrations

Ideal for demanding environments

Installation convenience of a single product

Range of grades available

Flexible and easy to install

Prevent ringing in lightweight precision equipment frames

Reduce hydrodynamic vibrations in massive ship hulls