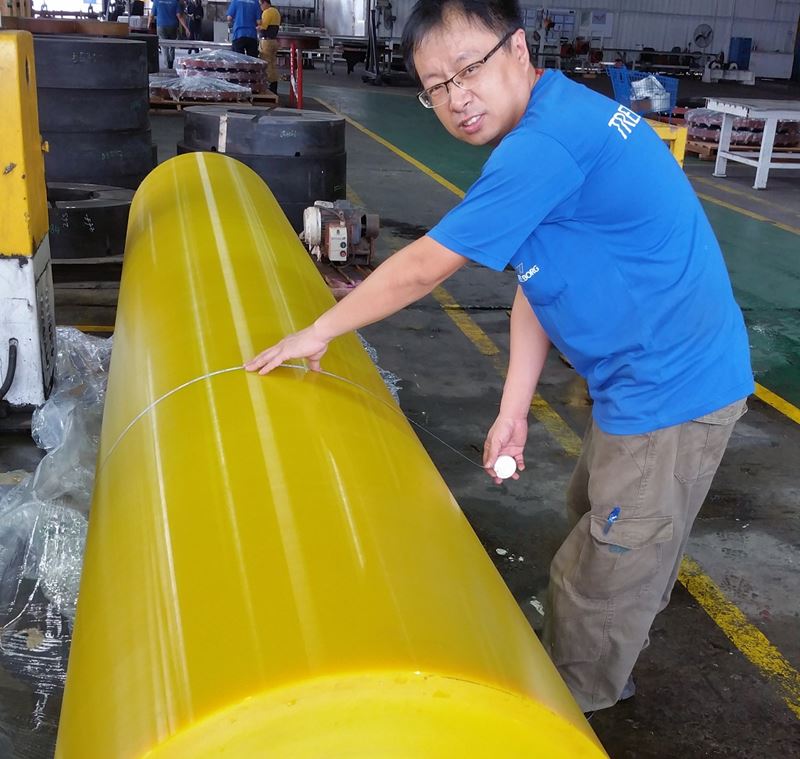

Vessel operators use our polyurethane tensioner pads and conveyor rollers to ensure that they get reliable performance under extreme conditions. We provide both recovery and new build services. Our range of products includes stinger rollers, vertical rollers, horizontal rollers, and tensioner track pads.

Prior to production, batch samples are subjected to rigorous tests including abrasion resistance to ensure the polyurethane pads and rollers are suitable for concrete coated pipes.

With a range of polyurethane hardnesses (83~95 shore A) to cater to different load specifications, our pads and rollers have a high load-bearing capacity.

Trelleborg uses specially selected polyurethane with high degradation resistance in seawater, and selected polyurethane formulated with additives to enhance it’s ozone and UV resistant attributes for the pads and rollers.

| Physical properties | Specification |

|---|---|

|

Hardness / shore A |

90 |

| Tensile strength / psi | 4,500 |

| 100% modulus / psi | 1,100 |

| 300% modulus / psi | 2,100 |

| Tear strength, D470 / pli | 85 |

| % Elongation | 420 |

| Compression set (22hrs at 70°C / % | 30 |

| Cured specific gravity | 1.10 |

Extreme abrasion resistance for concrete coated pipes

High load-bearing capacity

Excellent seawater resistance

Excellent ozone and UV resistance

Short delivery

Offshore pipe laying