By combining glass and air, manufacturers can incorporate high performance micro sized hollow glass or plastic microspheres (also known as microballoons) and macrospheres embedded into a thermoplastic of thermoset polymeric matrix, producing closed-cell foam materials to meet demanding strength and weight specifications.

Material properties

- Low density

- High strength to weight ratio

- Low thermal conductivity

- Low coefficient of thermal expansion

- High glass heat distortion temperature

- Low water absorption

- High bulk modulus

- Low dialectric constant

- Low acoustic impedance

Material benefits

- Tailored tot meet demanding strength, weight and electrical specifications for customers in a variety of markets

Applications

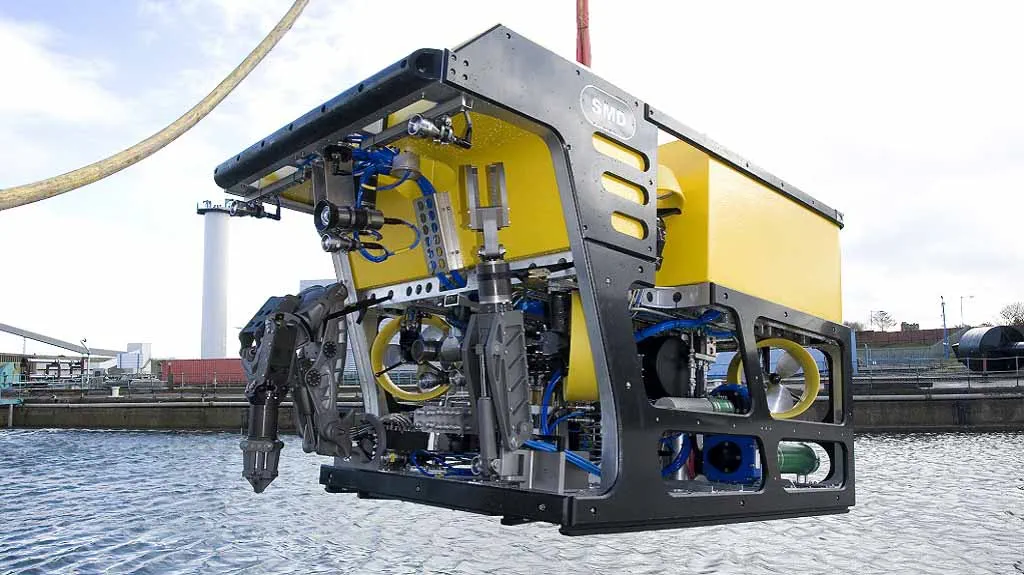

- ROV/AUV robot buoyancy vehicles

- Buoyancy modules/units

- Down hole technology

- 5G telecommunications

- Thermoforming plug assist

- Tooling boards for automotive and aerospace applications

- Acoustic applications such as smart gas meters