Reduce CO2 emissions and noise

Watertight Solutions

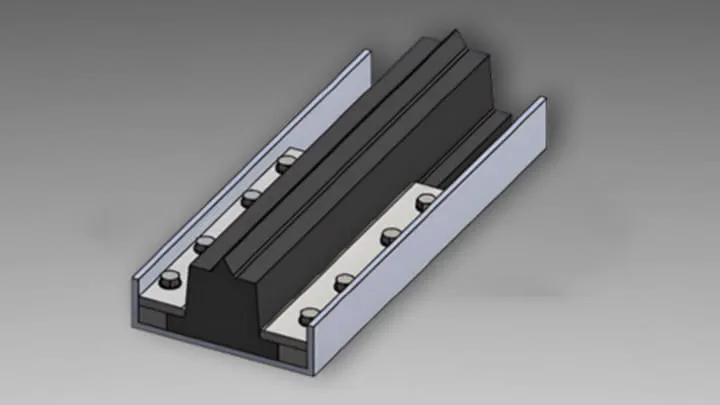

While creating a watertight dry dock may seem straightforward in theory, the reality is far more complex. To increase operational efficiency, working conditions, and avoid environmental risks, non-engineered extruded seals or wooden solutions are not enough. Trelleborg Marine & Infrastructure’s dry dock sealing systems are engineered for superior watertightness, featuring a unique polymer structure and installation clamps.

Delivered as a fully continuous design, the system eliminates weak points and streamlines installation by being custom-manufactured to match door specifications. Additionally, the rubber compound used in the gasket’s body is tailored to meet the specific characteristics and demands of each dry dock, ensuring optimal performance and reliability.

Delivered as a fully continuous design, the system eliminates weak points and streamlines installation by being custom-manufactured to match door specifications. Additionally, the rubber compound used in the gasket’s body is tailored to meet the specific characteristics and demands of each dry dock, ensuring optimal performance and reliability.

Delivered as a fully continuous design, the system eliminates weak points and streamlines installation by being custom-manufactured to match door specifications. Additionally, the rubber compound used in the gasket’s body is tailored to meet the specific characteristics and demands of each dry dock, ensuring optimal performance and reliability.

Delivered as a fully continuous design, the system eliminates weak points and streamlines installation by being custom-manufactured to match door specifications. Additionally, the rubber compound used in the gasket’s body is tailored to meet the specific characteristics and demands of each dry dock, ensuring optimal performance and reliability.Benefits

No auxiliary pumps required

Engineered solution

Designed to your specification

Less fixation material

Less steel required

High tolerance bandwith

Excellent load absorption

High compression capacity

Less damages

Continuous design

Lower maintenance need

Solutions

Dry Dock Sealing System

Real-world Success Stories