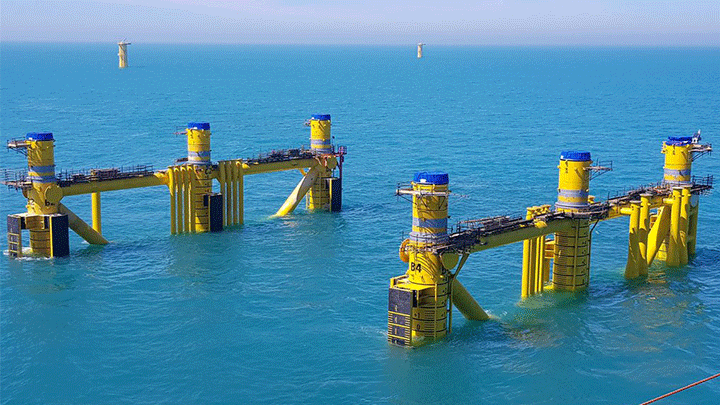

The float-over installation method is a highly effective and proven technique for positioning the heavy topside of offshore oil & gas platforms or offshore wind substations at sea. The process involves a heavy transport barge delivering the topside structure to the installation site. At this point, the barge carefully maneuvers into position between the jacket legs, aligning the topside with the substructure before ballasting it slowly into place.

Given the harsh offshore conditions, our float-over solutions are engineered to ensure seamless transportation and installation, safeguarding both the topside and substructure throughout the mating process.

Our Leg Mating Units (LMUs) are crucial during this operation, enduring significant vertical and horizontal compression as the topside deckleg cans come into contact with the jacket legs. To manage barge sway and stabilize the mating process, our Sway and Surge Fenders (SSF) come into play. Following this, our Deck Support Units (DSUs) facilitate the transfer of the topside's weight from the barge to the substructure, ensuring a smooth and controlled transition.

Engineered with precision, LMUs feature a robust steel structure with high-performance elastomeric pads. These pads, whether installed on the topside or substructure, absorb substantial loads and minimize the risk of damage during weight transfer. They effectively manage both static and dynamic forces, as well as horizontal movements induced by sea conditions, throughout the float-over operation. Once installation is complete, the topside leg cans are securely welded to the substructure.

Tailored for each project, our LMUs are subjected to stringent testing to guarantee superior performance and reliability. Proven across numerous global projects, our LMUs exemplify the highest standards of safety, quality, and engineering excellence in float-over installations.

Benefits

Applications

- Oil & gas topside

- Mining and LNG terminal construction

- Offshore Wind High Voltage Direct Current (HVDC)

- Decommissioning topside