Our Module Bearings (MB) for FPSO and FLNG applications are expertly engineered to handle heavy loads with precision, providing exceptional control, dampening, and protection. These advanced laminated rubber bearings are installed between the hull stools and modules on the vessel, allowing for effective accommodation of axial, shear, and rotational movements. This integration significantly mitigates load shifts and reduces noise, enhancing overall operational efficiency.

Utilizing state-of-the-art modeling techniques such as Finite Element Analysis (FEA), we accurately predict stress-strain behavior and analyze the fatigue life of our bearings. This rigorous approach ensures that each MB is designed to meet specific project demands, offering flexible support for vertical, horizontal, and rotational loads. The result is a resilient elastic link between rigid structures, which not only reduces material fatigue but also optimizes load distribution and vibration dampening.

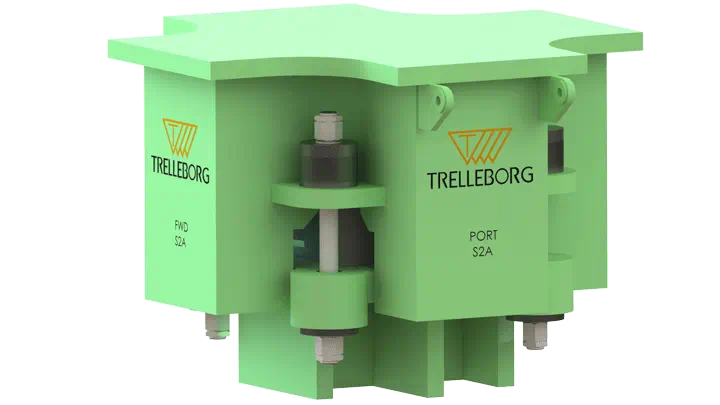

Our MBs are meticulously manufactured from layers of rubber and steel, which are vulcanized together to form a robust yet flexible bearing capable of supporting substantial loads. Often lined with steel, these bearings are engineered to accommodate a wide range of axial motions, displacements, and rotational movements across various designs.

We provide a comprehensive range of high and medium load bearings tailored to meet specific project requirements. Widely used in the offshore oil and gas industry, particularly in FPSOs and FLNGs, our MBs deliver essential vibration isolation for processing modules. Additionally, our specially formulated elastomer compound offers superior resistance to oil-based process liquids, ensuring long-term durability and reliability in challenging offshore environments.

Benefits

Applications

- FPSO

- FLNG