Product Groups

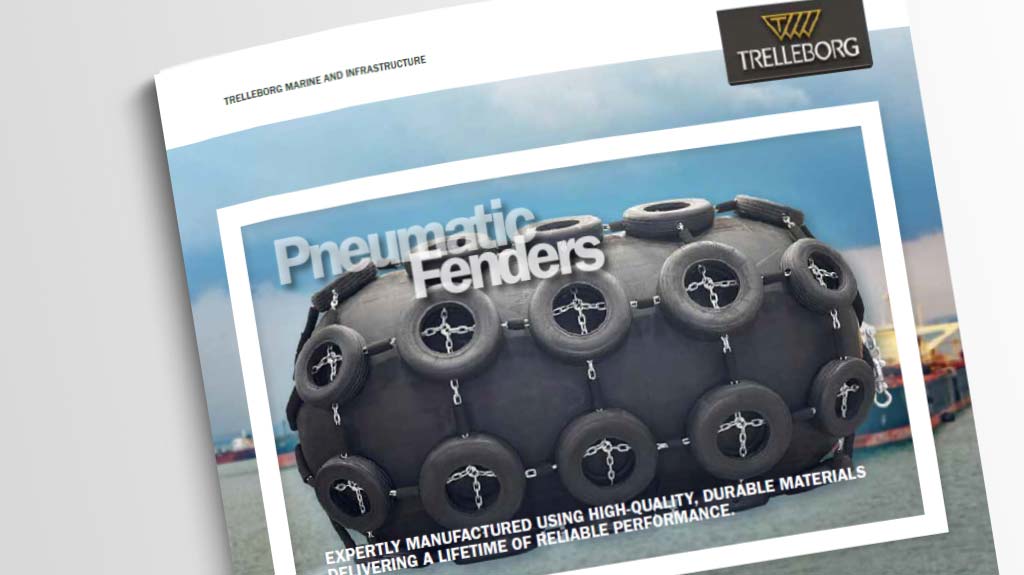

Floating Fenders

Floating Fenders are ideal for permanent and semi-permanent port applications and for offshore ship-to-ship transfers. Fast and easy to deploy, Trelleborg’s ISO 17357-1:2014 quality assured fenders ensure large clearances are maintained between the hull and jetty or other vessels. Risk of damage during mooring is minimized, protecting people and cargo. Trelleborg supplies a wide range of sizes and in standard or high-pressure versions. Smaller fenders can be supplied as Hook type. Larger fenders are commonly fitted with a chain-tyre net (CTN) for added protection. For navy ships, a grey body is also available.