Aerospace

As airplane designs focus on flying at higher altitudes and speeds for longer periods, the many hydraulic systems onboard must adapt. Today's conditions can include temperatures above 600°F (315,5°C), temperatures as low as -65°F (-54°C), and pressures up to 5,000 psi (345 bar)

This article was originally published in the August 2020 issue of Fluid Power Journal. It is reposted by permission.

Automotive & eMobility

Matching Elastomer Seals to Biofuel Applications

As the world attempts to reduce its dependence on fossil fuels, biofuels are now a reality. Brazil and the U.S. were early adopters of this alternative fuel for transportation but now its use is expanding in Europe, with Germany, France and Spain leading the way.

By Harlan Hart, Technical Manager e-mobility for Trelleborg Sealing Solutions.

Recognising that a specialised sealing solution was needed for e-Mobility applications, Trelleborg Sealing Solutions has developed two new seals that could help noticeably extend the distance travelled by electric vehicles between charges, as Harlan Hart, technical manager, e-Mobility, explains

When Electric Vehicles Take Over

By Jeff Kerns, published in "Machine Design Magazine"

Are supply chains, materials, and drivability of EVs helping or hurting?

First appeared in Machine Design

New Seals Reduce Friction for Electric Vehicle Adoption

By Harlan Hart, Technical Manager e-Mobility for Trelleborg Sealing Solutions, published in "Machine Design Magazine"

Increasing electric vehicles driving range is more than just a matter of batteries and motors.

First appeared in Machine Design

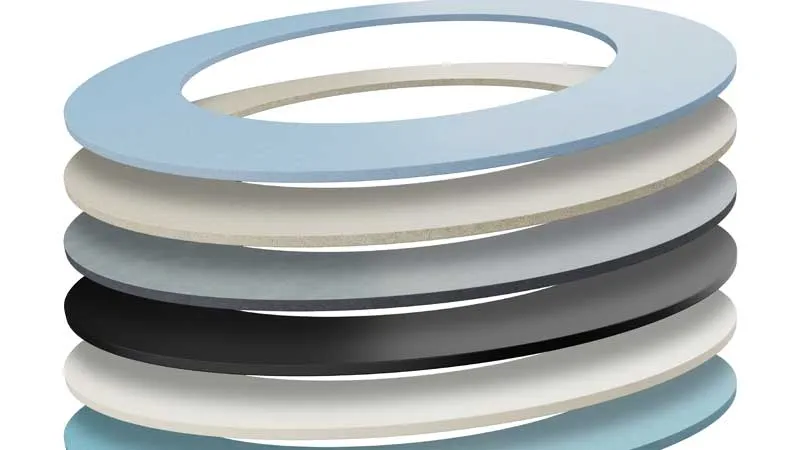

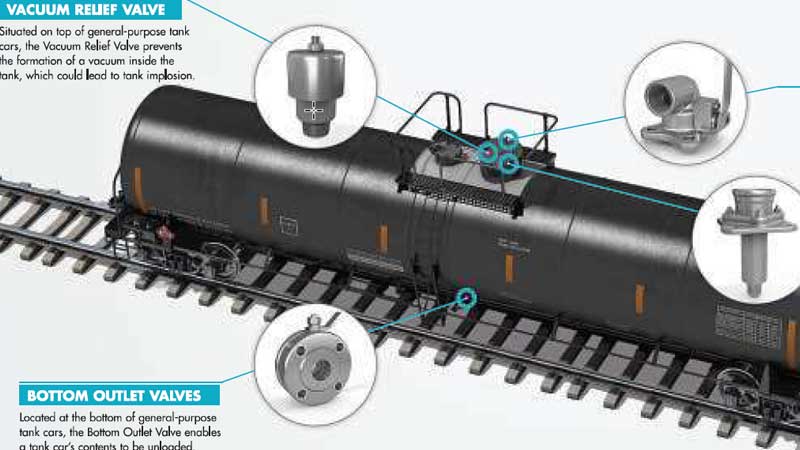

As a matter of flat: The importance of high-quality flat seals in chemical transportation

Reprinted with permission from Bulk Transporter. Find the original article at BulkTransporter.com

Secure Transport of Chemicals - Sicherer Transport von Chemikalien

By Marco Schildknecht, Segment Manager Chemical & Processing Europe, Trelleborg Sealing Solutions

Even when exposed to the most aggressive chemicals, the two sealing materials Isolast J9503 and Isolast J9567 perform very well. They seal reliably under extreme conditions and have a long service life.

This article is in German and was originally published in August 2022 in cav - Prozesstechnik für die Chemieindustrie It is reposted by permission, copyrights are reserved to the publication.

Chemical Transportation

Energy

Sealing Considerations for Fire-Safe Valves

A valve that can temporarily survive a fire scenario gives personnel time to escape and find safety. "Fire safe" is the term used to describe valves that survive temperature extremes from a stimulated blaze. They can be choke, ball, gate or other designs and typically operate with a valve stem that rotates, reciprocates or is a quarter-turn type.

By Eric Bucci, Trelleborg Sealing Solutions

Originally published by Chemical Engineering

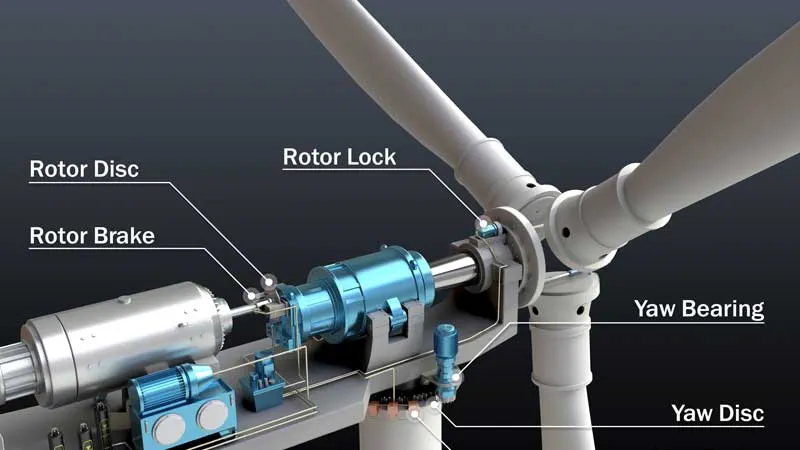

Bearing considerations for offshore wind platforms

Trelleborg's Orkot composite bearing materials are well suited for demanding high-load applications

like offshore wind platforms.

Byline: Mark Hampton, Product and Innovations Manager, Trelleborg Sealing Solutions

Originally published by Bearing Tips.

Seal testing options for hydrogen storage and transport

As the world transitions towards a net zero future, hydrogen is growing in importance as one of the key elements that will help deliver a more sustainable future.

This article originally published by Design World

Maximizing wind turbine efficiency through optimized hydraulic sealing

Advanced seal designs that prevent wear, increase service life, and reduce friction can ensure uptime in pitch cylinders and brakes.

This article original ran in Sealing & Contamination Control Tips

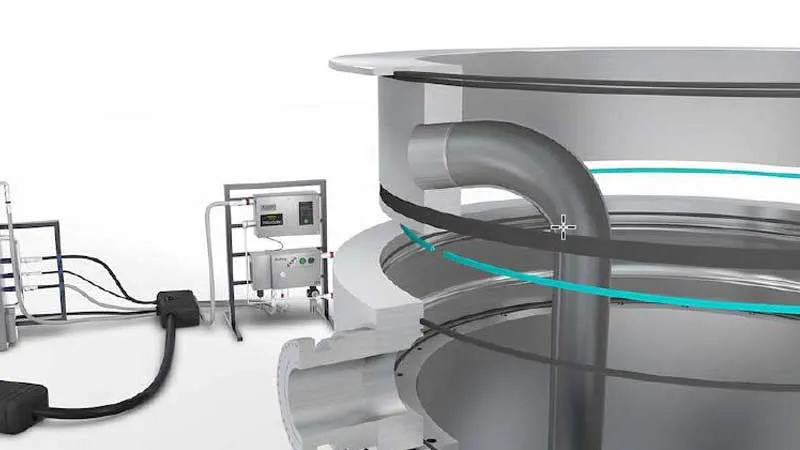

Minimizing Equipment Downtime with In-situ Seal Welding Technology

The ideal solution is for completion of any seal repairs or replacements on FPSO vessels to be completed offshore, in-situ, to speed up the process and minimize equipment downtime.

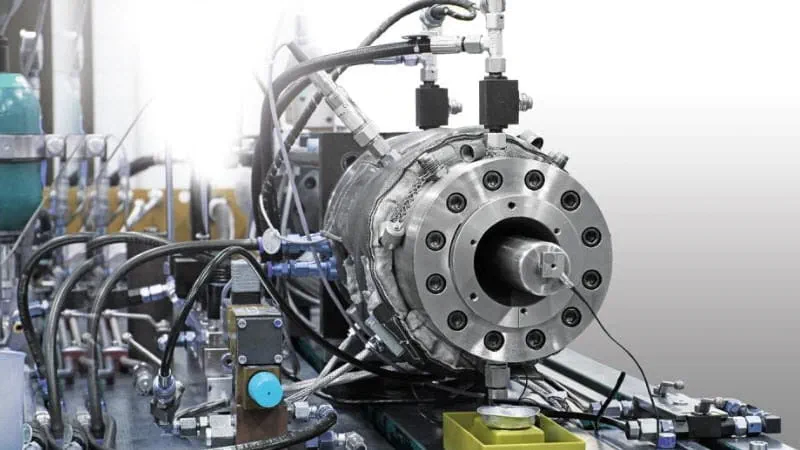

Trelleborg introduces XploR S-Seal

By Eric Bucci, published in "Rubber & Plastics News"

Trelleborg Sealing Solutions recently launched XploR S-Seal and XploR FSSeal, extrusion-resistant elastomers the company developed for demanding high temperature and high-pressure sealing environments in the oil and gas industry.

Trelleborg's tensioner cylinder seals exceed 20-year lifecycle rating

By Mary Gannon

Seals used in offshore rig tensioner cylinders must meet the same rigorous lifecycles as the

cylinders themselves. Because offshore environments are harsh and installation and maintenance

can be difficult, tensioner cylinders must have a 20-year life. That was why, more than 20 years

ago, Trelleborg Sealing Solutions conducted research, determining that its seals could last this

necessary lifecycle.

Perfluoroelastomer (FFKM) elastomers offer exceptional thermal stability, outstanding long-term compression set and almost universal chemical compatibility – delivering long life in the most aggressive of media, including hydrocarbon and aqueous media, common within oilfield applications.

As the oil and gas industry evolves, sealing materials are required to work effectively in more challenging environments. This article details the effects of exposure to water-based hydraulic fluids and High-Pressure/High-Temperature (HPHT) fields on common sealing materials.

Fluid Power & Off-Highway

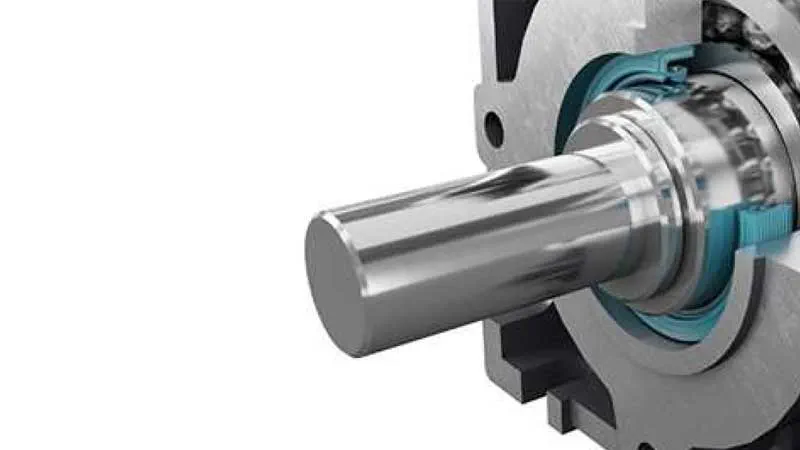

From managing contamination caused by dirt and mud to helping precisely move heavy loads at construction sites, seals used in hydraulic motors, gearboxes and pumps for rotary fluid power applications face significant demands. To meet the challenges, seal suppliers are investing in advanced test rigs...

Originally published in Fluid Power World Magazine

The Australian mining industry presents unique challenges when it comes to equipment durability and operational efficiency. This article examines the role of sealing technology in addressing those challenges. It provides an overview of how advanced sealing solutions are engineered to perform under extreme conditions, ensuring equipment reliability, reducing downtime, and maintaining safety standards in demanding mining environments. It will also cover the key considerations in selecting the right sealing materials and designs for specific mining applications.

Originally published by Australian Mining

How Hydrogen could shape the future of Fluid Power

A partner focused on innovations in hydrogen sealing can provide a comprehensive suite of solutions designed to address future challenges for fluid power applications. Trelleborg’s H2Pro™ portfolio of over 20 materials exemplifies this dedication.

Originally published by Fluid Power Journal

Aiding in the Balancing Act: Removing the Burden of Innovation for Fluid Power Customers

By Michael Cook, Global Segment Director Off-Highway, Trelleborg Sealing Solutions. Originally published by Fluid Power Journal

We need to look at ways to help each other formulate new solutions with minimal effects on daily business operations. One way to do this is by pursuing a shared innovation approach across the fluid power supply chain.

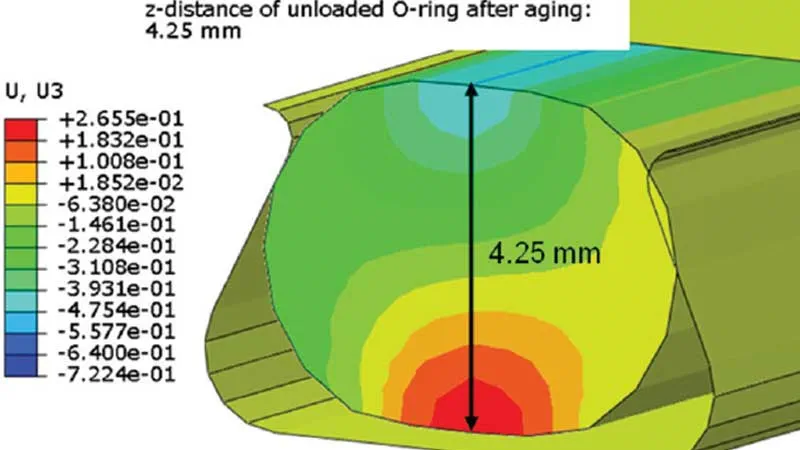

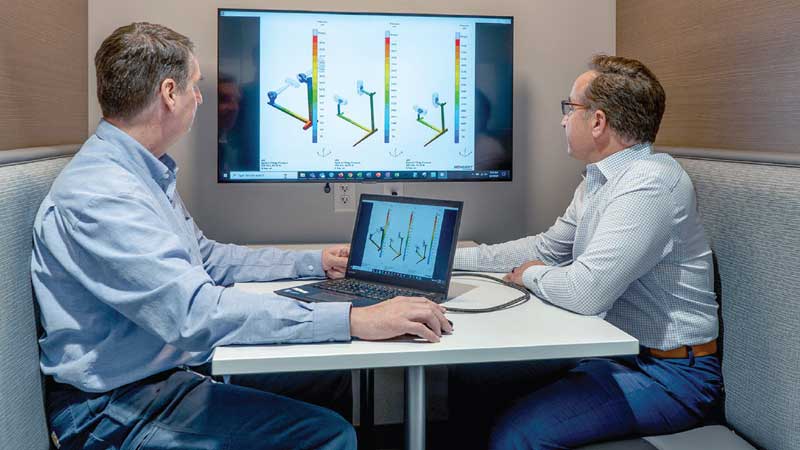

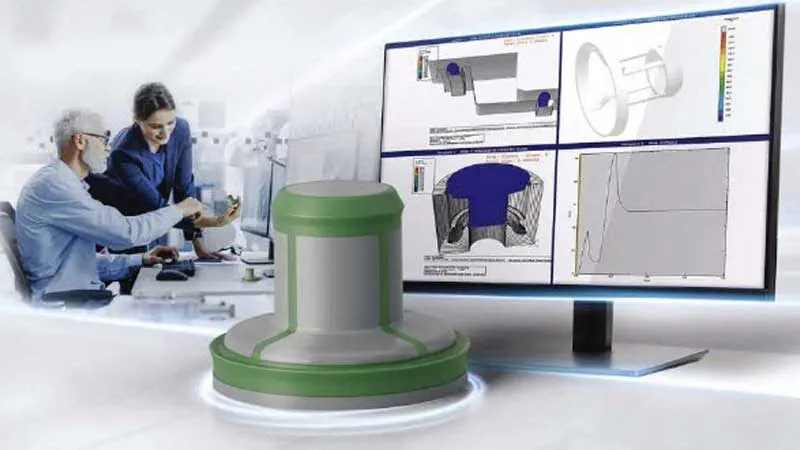

Simulations reveal valuable information about Fluid Power Components

This article was originally published in the Fall/Winter 2023 issue of Your World in Motion and is shared with permission from the Canadian Fluid Power Association (CFPA). To learn more about CFPA and to read the full issue at no cost, visit https://cfpa.ca/.

To achieve optimal efficiency, fluid power applications and their sealing components need good friction characteristics and long life to reduce maintenance. Engineering simulations can help original equipment manufacturers (OEMs) succeed in an environment where the demands for efficiency are increasing.

Why stocking standard products pays off for OEM and supplier relationships

By Scott Christensen, originally published by "Sealing & Contamination Control Tips"

Original Equipment Manufacturers (OEMs) and their tier suppliers rely on sealing partners for a wide range of services and capabilities. An experienced and knowledgeable sealing supplier can provide everything from high-quality custom sealing solutions and FEA analysis to online tools and resources for engineers.

All Around the World: Circular Sustainability for Fluid Power

In today’s environmental and economic landscape, it is critical for fluid power component manufacturers and seal suppliers to incorporate sustainable methods into design, manufacturing, and production practices through design thinking for circularity and circular products.

This article was originally published in the November 2022 issue of Fluid Power Journal

Spotlight on Sealing Solutions for Fluid Power and Off-Highway

Ensuring performance in extreme conditions, industrial seals meet unique application needs.

First appeared in Machine Design

No-Leak Zone: The Mighty Mechanical Face Seal

Mechanical Face Seals, also called lifetime seals, floater seals, duo cone seals or toric seals are important to the long-life function of heavy equipment in agriculture, construction and mining.

This article was originally published in the February 2022 issue of Fluid Power Journal. It is reposted by permission.

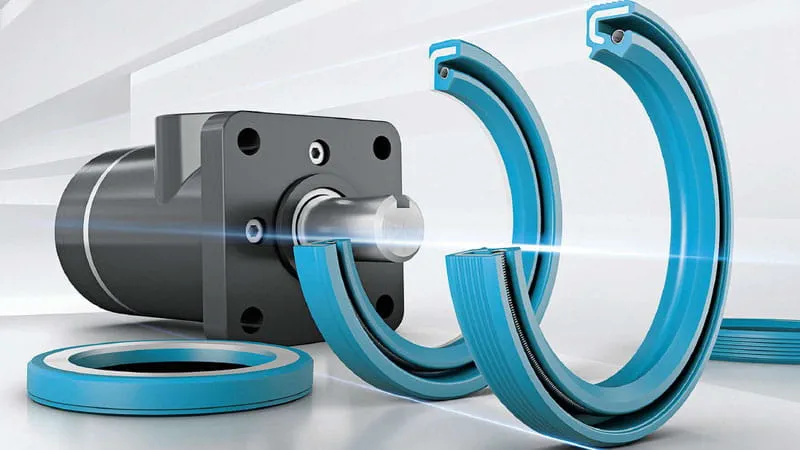

Advancements in Double-Acting Rotary Seals Prove More Effective

By Beth Figliulo, Fluid power segment manager, published in "Electronic Component News", Dec. 2018

How specialized Rotary Seals are alleviating fluid power pressure build-up for high-speed, high-pressure applications

Modern machinery, equipment and motors fitted with hydraulic cylinders are becoming more powerful, which means that the hydraulic systems therein are increasingly subject to higher operating pressures and temperatures.

The right seal reduces contamination in hydraulic systems

Learn what causes contamination and how to choose seals that protect against it.

Trelleborg Sealing Solutions has developed a unique engineered seal– specifically for use within Central Tire Inflation systems. Turcon® Roto L is the first ever active seal, engineered to only provide sealing when required. Eliminating friction and torque, this extends the seal life of axle systems and can significantly reduce fuel consumption for vehicle operators.

Zero-Leak Wipe Systems Fluid 'Weepage'

Hybrid robots combining hydraulic and electric systems are becoming more common in assembly lines and warehouses. Hybrid hydraulic and electrical designs require special care when specifying hydraulic sealing systems because weepage of even a light coating of hydraulic fluid can negatively affect electrical system performance.

This article was originally published in the February 2022 issue of Fluid Power Journal. It is reposted by permission.

High Modulus Plastics Can Play a Key Role in Off-Highway Vehicles

By Tom Zozokos, Product Line Director, and Beth Figliulo, Fluid Power Segment Manager Americas, Trelleborg SealingSolutions.

Co-injection molding is one technology of interest for those designing hydraulic systems for off-highway use. This allows two polymers to be combined in a single operation to create multiple functions in one component.

This was originally published in OEM Off-Highway.

Boosting performance in hydraulic systems with alternative coatings

By Beth Figliulo and Michael Cook, Trelleborg SealingSolutions.

Taking a holistic approach to sealing solutions in hydraulic systems using chrome alternatives helps engineers achieve optimum function.

Materials for Maximum Wear Ring Performance

Published in "Flow Control", May 2018

Read how Wear Rings can extend the life of a hydraulic system

Food & Beverage Processing

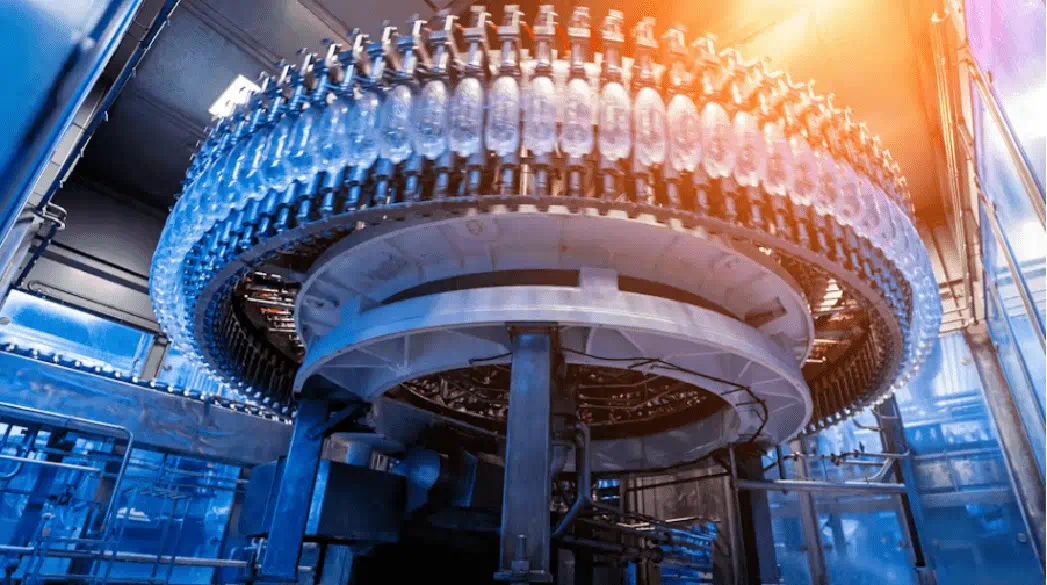

Processing Q&A: Rotary fillers with Trelleborg's Caio Beraldo

Each piece of equipment and machinery used in the food and beverage processing industry is different and has a unique set of sealing requirements. Caio Beraldo, technical manager for food, beverage and water at Trelleborg, discusses the uses and sealing needs for rotary fillers.

This article appeared on Processing Magazine’s website

Processing Q&A: Horizontal mixer sealing with Trelleborg's Caio Beraldo

From mixers and food pumps to valves and fillers, the range of equipment and machinery used in the food, beverage and water industry is diverse. Each has its own set of sealing requirements and understanding these critical components takes expertise.

This article appeared on Processing Magazine’s website

Processing Q&A: Vertical mixer sealing with Trelleborg's Caio Beraldo

Trelleborg's Technical Manager for Food, Beverage and Water, recently connected with Processing to discuss the uses and critical sealing components for vertical mixers.

Selecting the right seals for food and beverage processing

Understanding common seal materials and factors that affect performance can help ensure the seling solution best meets the requirements for the application

Engineered Solutions for Smart Appliances with LSR Processing

The Research and Markets Institute (researchandmarkets.com) projects the global household appliances industry to reach an estimated value of US$ 324.2 billion by 2019. Amongst the major drivers are growing affluence of the middle-class population in emerging markets, higher disposable incomes, and more per capita spent on lifestyle products in increasingly urbanized environments.

Product change without aroma carryover

(Article language: German)

Trelleborg Sealing Solutions has partnered with Krones, a specialist in beverage bottling, to analyze the reasons behind unintentional flavor carryover during the filling process. The companies found elastomer sealing components to be a relevant factor in aroma carryover and that the selection of the optimum sealing material is crucial in preventing the transfer of flavors from one filling process to the next.

David Kaley — Trelleborg Sealing Solutions; Edited by Mike Santora

With stainless steel and other metals so predominant in industrial food manufacturing equipment, it may seem unusual to suggest a more significant role for plastic wear rings and bearings. But for a broad range of food production and transportation machines, advanced polymers are an effective way to reduce friction and handle load instead of traditional metal bearings.

Trelleborg Seals help keep food and beverage industry clean

By David Kaley, published in "Rubber & Plastics News"

One of the most important aspects for the food and beverage industry is sterility. Preventing cross-contamination on the plant floor is crucial. Any company creating pieces of equipment needs to adhere to the industry's strict regulations.

Smart Engineering Solutions for Smart Appliances with LSR Processing

By Ursula Nollenberger, published in "appliance DESIGN"

The global household appliances industry is seeing a steady influx of technologically advanced appliances that deliver innovative, smart features to save the user time and make life more comfortable. This article demonstrates the role custom-engineered LSR parts have in this segment.

Industrial Automation

Robotics Tomorrow conducts a Q&A with Segment Manager David Kaley to learn more about our Stefa Mini Solutions and how they are alievating industry challenges.

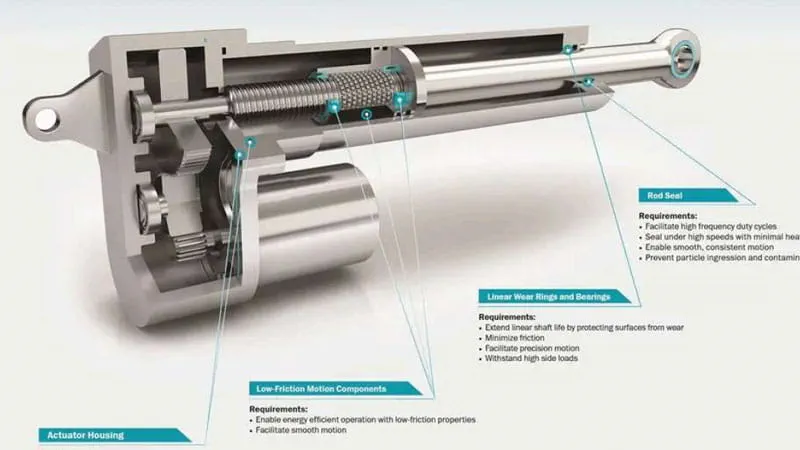

Achieving high and consistent speeds in linear actuators can be a challenge and is determined by the motor, gearbox, shaft size, thread pitch, bearings, lead screws and seals. Seal material and design is often a limiting factor for speed and a common failure point for linear actuators.

Originally published by Power Transmission Engineering

David Kaley, Trelleborg global segment manager for industrial automation, shares his expertise on speed reducers covering what they are, how they work and key considerations for correct sealing in this article.

Originally published by Power Transmission Engineering

Trelleborg shares Insights on Sealing Needs for Industrial Robots

Robots in industrial applications need to operate with precision to accurately perform within their work envelopes at specific speeds and accelerations. This type of precise movement requires the help of several seals.

Originally published by Power Transmission Engineering

Trelleborg shares Insights on Sealing Needs for Electric Motors

From electric motors and linear actuators to robots and gearboxes, the range of equipment and machinery used to crate automation in industrial applications is divers. Each has its own set of sealing requirements and understanding these critical components requires many years of experience. In this article David Kaley, Trelleborg's global segement manager for industrial automation, shares his insights on sealing needs for electric motors.

Originally published by Power Transmission Engineering

Motors and More: Achieving Greater Effieciency in Industrial Automation Applications

Originally published on Automation.com

Industrial automation is highly beneficial because it decreases production times, improves quality and increases productivity in a world where

customers expect quick turnaround times.

By Darren Conway, Global Product Line Director, Trelleborg Sealing Solutions

Many industrial sectors, including aerospace, semiconductor, automotive and biopharmaceutical, require rotary seals as original equipment manufacturers (OEMs) switch from hydraulic to electric motor systems for greener solutions and improved product performance.

Polymer Materials

High-performance plastics (HPPs) excel in high-temperature environments, high-pressure applications and demanding mechanical settings. With their ability to reduce weight, improve energy efficiency and resist corrosion, HPPs are valuable in sectors such as automotive, aerospace, industrial automation, processing industries and semiconductors.

Originally published by Plastics Technology

High-Performance Plastics: The Value and Challenges of High-Volume Precision Molding

The use of high-performance thermoplastics can reduce time and expense during design, prototyping and manufacturing. They are recyclable, able to bond to differing materials and lighter than their steel counterparts.

Originally published by Machine Design

There is no one-to-one replacement

What opportunities and risks the seal supplier Trelleborg sees in the impending ban on PFAS substances (per- and polyfluoroalkyl substances), which is causing nervousness among manufacturers, processors and users.

This is the way—to safe chemical transport

By Thijs Menzel. Reprinted with permission from Bulk Transporter Magazine. Find the original article at BulkTransporter.com

Chemical compatibility, material testing, root cause failure analysis among the critical keys to success, sealing expert says

The right seals and materials keep chemicals moving

ByThijs Menzel

The world relies on chemicals to provide the essentials of modern life and they are the basic building blocks of everyday items; from the fertilizers that help grow our food to the beds we lie on, from the shoes on our feet to the cars that we drive. Transporting those chemicals safely to where they are needed, is a major logistical effort that requires advanced sealing technology.

Biolubricants & Seals: Users and their providers need to pay attention to fluid compatibilities

By Joe Savina, published in "Processing Solutions"

Biolubricant use is on the rise as companies look for more sustainable ways of doing business. Read this article to find out more about the special design considerations required due to how these lubricants may react to equipment components and seal materials.

Published on "ChemInfo", May 2018

The chemical compatibility of a seal with the fluids in a system is critical to obtaining a reliable, long-lasting seal. Here are some considerations for choosing the right material for a given chemical sealing application.

Polyurethane (PU) materials offer outstanding wear, extrusion and abrasion resistance with good elasticity and low compression set.

Looking Beyond Chemical Compatibility Charts: Matching Plastic and Elastomer Seals with Fluids

By Lucy Heyduk and Tim McCulfor, Trelleborg Sealing Solutions

Chemical compatibility charts are often used as a quick and concise way to match the proper fluid with a seal. However, there is much more to consider with the chemical compatibility of a seal in relation to the fluids in a system. This information is critical to gaining a reliable and long-lasting seal — and the selection process can be daunting.

This article was first published in Bulk Transporter.

Seal Design & Technology

Where the rubber meets the road for component design and manufacturing

The development of a custom rubber seal can be challenging.

Relying on industry specialists and considering potential manufacturing

methods and production volumes will enable you to navigate the

innovation process.

This article was first published in Design World.

Inventory Management Systems Play an Essential Role Now and Into the Future

As the economy reopens and demand for manufactured products returns to normal, it has become challenging to manage inventory of the parts needed for production. While no one product or service can solve all of these problems, inventory management systems have become an increasingly useful tool for managing labor and supply chain issues. This article reviews the current situation and how one new automated inventory management system can help alleviate some of the pain of C-Class inventory management.

From Deformation to Calibration: Installing O-Ring Energized Piston and Rod Seals

By Beth Figliulo and Michael Cook, Trelleborg SealingSolutions.

Avoid seal installation issues that lead to leaks and lost productivity.

Composite Simulation Grows MORE ROBUST

By Kenneth Wong

The transition from metal to composite is one of the most recent significant changes in manufacturing.

The former material is isotropic, exhibiting uniform stretching and bending behavior in all directions. By contrast,composites are anisotropic. They stretch, bend and break differently in different directions, based on how the fibers are woven together and how the laminates are bonded. This fundamental difference throws many traditional simulation protocols and practices into chaos.

Reduce Vibration and Avoid Stiction in Seals

By Holger Jordan, fluid power segment manager, Trelleborg Sealing Solutions

Stick-slip is not always a big issue, but sometimes it can significantly

degrade performance. Potentially, it can cause damage, such as cracks in

steel work and strength loss, and even health problems for operators.

We look at solutions to combat stick-slip to lower vibration as well as to create damping solutions.

When one is better than many

By Ursula Nollenberger; Trelleborg Sealing Solutions; Published in “MEDengineering” (edition 2/2020)

As medical devices become ever more sophisticated and smaller in size, the challenge for the component manufacturer is how to fit multiple functions into a limited space. Multi-component LSR technology offers a solution to this, that in addition, provides designers with the latitude and flexibility to enhance their applications.

By Michael Cook and Kelly Volpenhein; Published in "Fluidpower Journal"

This article was originally published in the February 2019 issue of Fluid Power Journal. It is reposted by permission.

LSR for Added Value Industrial Applications

With global engineering and production facilities, state of-the-art cleanrooms and advanced automated processes, Trelleborg Sealing Solutions already offers its medical device, biotech and pharmaceutical customers specialized custom molded solutions that enhance their product offerings.

By Beth Figliulo, published in "Hydraulics & Pneumatics"

Understanding a seal's function isn't difficult - it keeps fluids in and contaminants out. Understanding how to get this done most effectively in a specific situation is an entirely different matter.

Semiconductor

Damping within Vacuum for Front-end Semiconductor Processes

By Kevin Kaufenburg, Semiconductor Business Development Specialist, Trelleborg Sealing Solutions

Manufacturing the latest design of tiny transistors presents challenges for semiconductor original equipment manufacturers (OEMs). As transistors shrink beyond ten nanometers, vacuum environments for semiconductor processes play a critical role...

This article was originally published by Semiconductor Digest.

Trelleborg Medical Solutions

Providing Biopharmaceutical Manufacturers with Cutting-Edge Material and Assembly Solutions

Article originally published in BioProcess International

Trelleborg experts leverage a reinforced polypropylene (PP) composite material´to make thin, light chromatography columns, using significantly less material than is needed for traditional options.

Device Development Excels in Rapid Development Centers

Design and material choices can have a long-term impact on manufacturing costs and effieciencies for medical device manufacturers. When they work together with experienced component manufacturers from the start of a project, they can save time, reduce costs, and produce premium quality products, while keeping an eye on the goal of a smooth transition to serial production.

Handy medical devices make life easier for people with chronic conditions, and automated dosing systems are gradually replacing regular injections of essential medication. Trelleborg cooperated with WACKER to develop a microinjection pump, the very heart of such devices.

Single-Use Systems: The Future of Biopharmaceutical Processing

Single-Use systems represent the future in biopharmaceutical processing of therapeutic drugs with significant advantages

over traditional reusable stainless-steel systems and partly disposable systems.

Water & Sanitary

Addressing Sealing Challenges Associated with Smart Meters

Smart gas meters enable companies, households and municipalities to remotely access data and device functionality through a network, such as Wi-Fi, a portal or a cellular phone network. The U.S. smart meter market is projected to reach $7.69 billion by 2027 at a CAGR of 10.47%, according to Allied Marketing Research.

By Jerry Schmitz, Global Segment Director, Trelleborg Sealing Solutions