Gutteling LNG White hoses can be supplied in two different types; Gutteling LNG White for LNG bunkering, Ship to Shore and industrial applications and Gutteling LNG White STS for Ship to Ship and LNG Bunker operations.

The reliability and safety has been proven during an extended design and qualification program. Since 2005 Gutteling LNG White STS hoses are in service for Ship to Ship LNG transfer operations around the World. They can be used in combination with loading arms and flexible pipelines. Gutteling LNG White hoses are produced and certified to international standards like EN 13766, IMO IGC, EN 1472-II, EN 12434 and PED regulations.

Design

WHAT MAKES US THE INDUSTRY LEADER

TYPE APPROVALS

A Type Approval is the mechanism which guarantees the consistency of the entire product range. In other words, a hose produced today is the same as one produced two years ago or two years from now!

INNOVATION

Gutteling stands always in front of new innovations. As an active member in Global guideline committees we guide operators and industrial partners to a safe future.

FAMILY

Following the company’s 25 year anniversary in 2015,

it is exciting to see that several employees are celebrating their 25th anniversary as well. It is the strength of our family that drives Gutteling forward.

TRUST AND CONSISTENCY

The fastest path from “I don’t know you” to “Do whatever you think is right” is consistency in all Composite Hose deliveries and predictability experience in Composite Hose technology.

GUTTELING CHEM BLACK HOSES

GUTTELING CHEM GREEN HOSES

GUTTELING CHEM RED HOSES

GUTTELING VAPER YELLOW HOSES

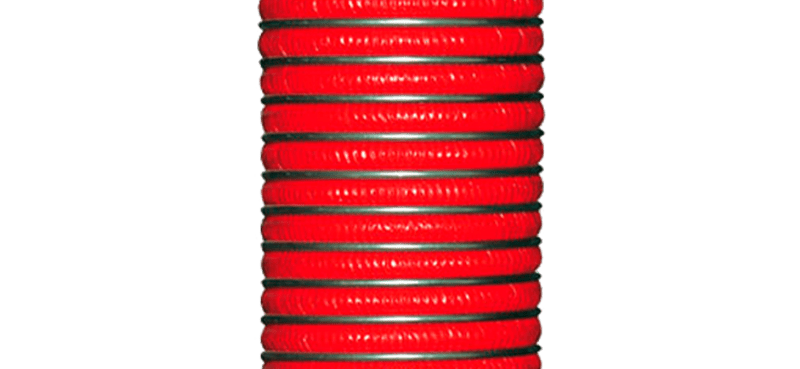

GUTTELING LNG WHITE HOSES

GUTTELING LNG WHITE STS HOSES

GUTTELING LPG WHITE HOSES

GUTTELING CHEM WHITE HOSES

GUTTELING BIO GREEN HOSES

GUTTELING TANKTRUCK BLUE

GUTTELING OIL BLUE HOSES

Contact us

Gutteling B.V. (head office)

Pelsertstraat 9 Rotterdam , 3044 CH Netherlands