We measure ourselves on your success

Our experienced teams are focused specifically on serving the medical markets and delivering value to customers globally through a strong set of core capabilities.

What are you looking for?

to support you from the earliest stages through to serial production and beyond

Equipment

to support the development of safe, timely and effective biological therapeutics

-

03.02.26

-

08.12.25

-

03.11.25

Products & Manufacturing Capabilities

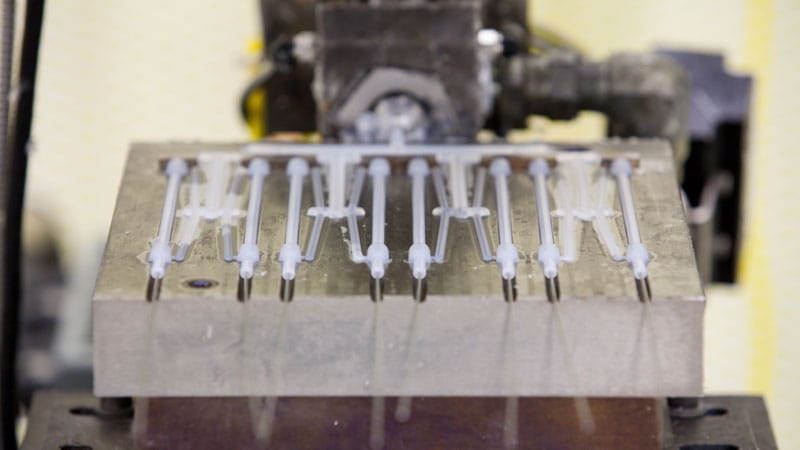

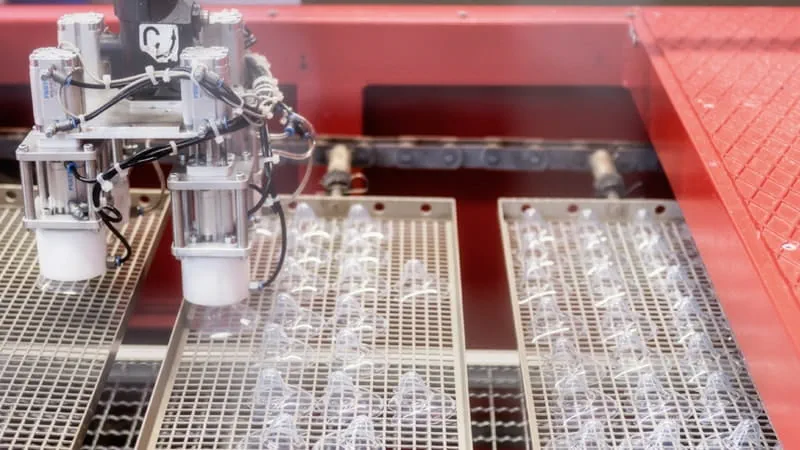

Excellence in Manufacturing & Quality

Global manufacturing and quality excellence to bring leading edge technology and an in-depth understanding of the challenges our customers must overcome to reliably develop and manufacture medical components and devices.

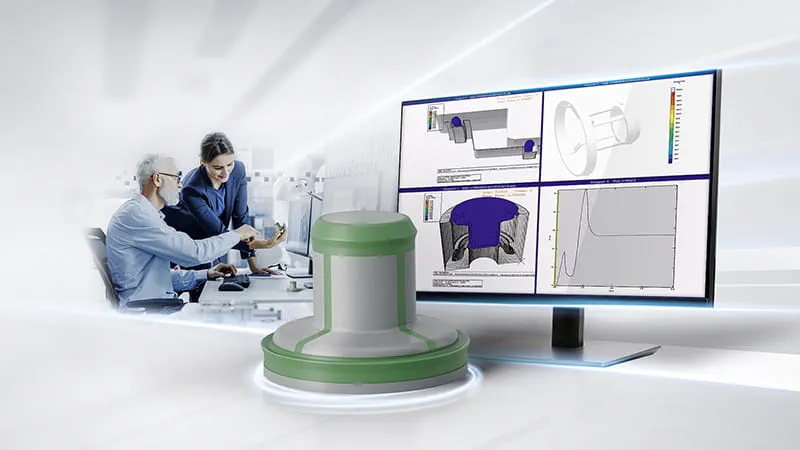

Engineering Expertise

Decades of experience enables Trelleborg to reliably manufacture complex designs to tight tolerances, optimize designs for ease of manufacturing, automate manufacturing processes and to develop novel solutions for customer challenges.

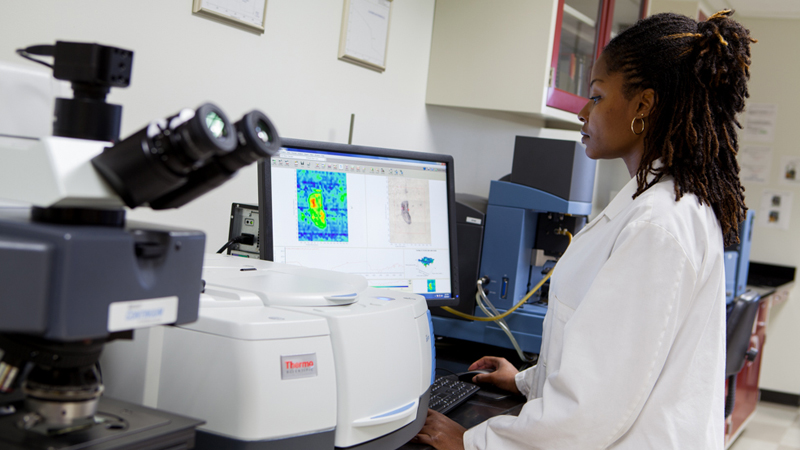

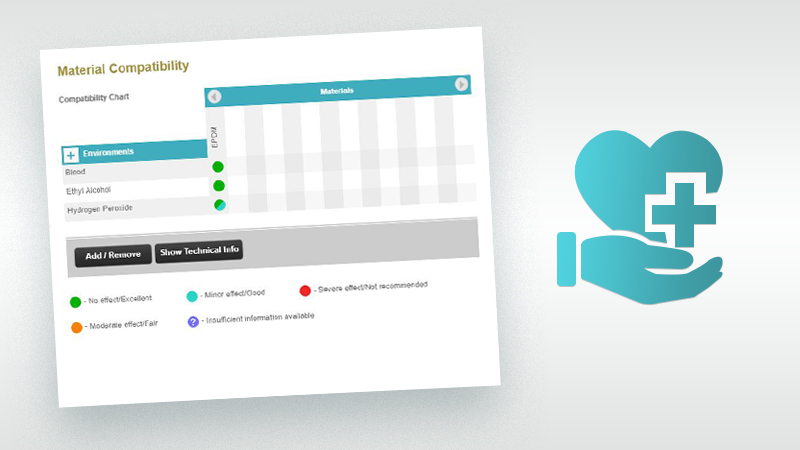

Deep Knowledge of Polymer Materials

Trelleborg finds novel solutions to customer challenges through our understanding of the interactions of materials, the manufacturing environment and the customer’s application.