FEA

- Latest techniques and software

- Reduces time to market

- Increases design quality and reliability

- Reduces overall costs

Using the latest FEA techniques and software, Trelleborg Medical Solutions accelerates time to market, quality of design and reduces overall costs of new and existing product designs.

Trelleborg Medical Solutions combines FEA with world-class engineering resources to design, develop and manufacture leading-edge solutions for the medical industry. By simulating the performance and behavior of a component within a virtual environment, rapid modifications and design iterations can be tested for viability; a process that would take years with conventional methods.

When FEA methods are combined with engineering expertise and a portfolio of tried and tested materials, the optimal material or product design for an application can be determined, leading to increased performance and reduced downtime.

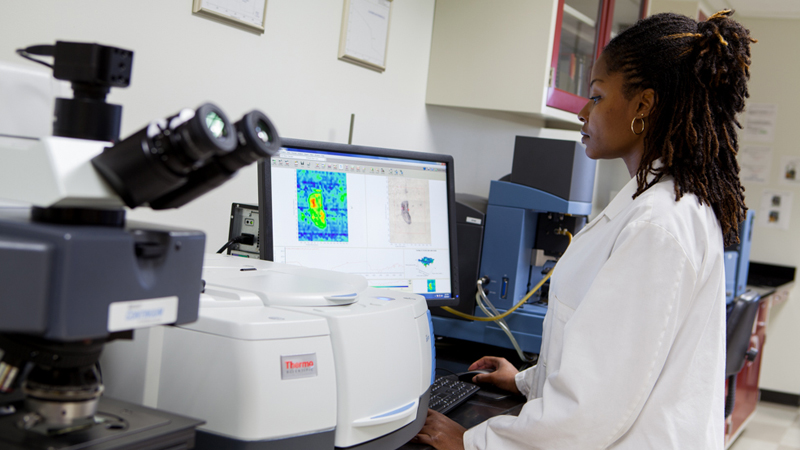

Failure Analysis

Optimize solutions based on detailed analysis of seal failure

- Analysis to reduce downtime and increase productivity

- Determine cause of seal failure

- Suggest new materials or improved designs

Failure analysis helps determine the underlying causes of seal failure to help select a more effective material or product for an application. By examining a failed seal and the application in which it was used, subsequent failures can be avoided. Seal failure can be caused by anything from loss of compression set to chemical degradation.

Trelleborg Medical Solutions supports customers with the analysis of the cause of failure and provides recommendations on more suitable materials or improved designs to reduce downtime and increase productivity.

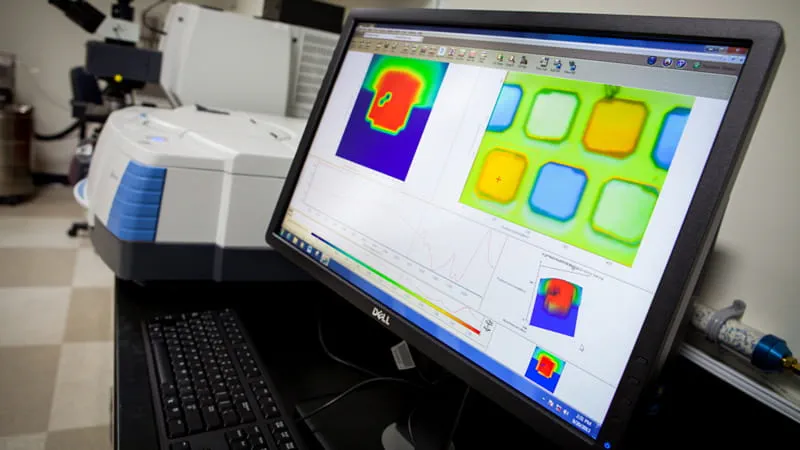

Product Testing

Key Benefits:

- Customized test methods aim to replicate application conditions

- Proven solutions with defined performance potential

- Reduced development time

- Increased confidence in the selected solution

- Global coverage for product testing; Americas, Asia and Europe

- Continuous Testing

The product test laboratories at Trelleborg Medical Solutions are constantly testing our seals and bearings to prove performance capabilities in service and identify the limits of each product. In-house custom-designed test equipment is used alongside testing in application through customer partnerships.

Typical test parameters include:

- Reciprocating, rotary and helical motion

- High and low temperature and pressure conditions

- Compatibility to a wide range of fluid media

- Short term screening and long-term endurance

- More Effective Solutions

Outputs include the condition of the seal, process media and mating parts, leakage and friction. Trelleborg Healthcare & Medical design engineers and applications engineers work closely with test engineers to ensure that test and application environments are closely matched.

Final validation of seals and bearings should always be conducted by the customer in an application test. However, the aim of our validation processes our aim is to ensure that customer tests are successful first time and that ultimately the most effective solution is specified.