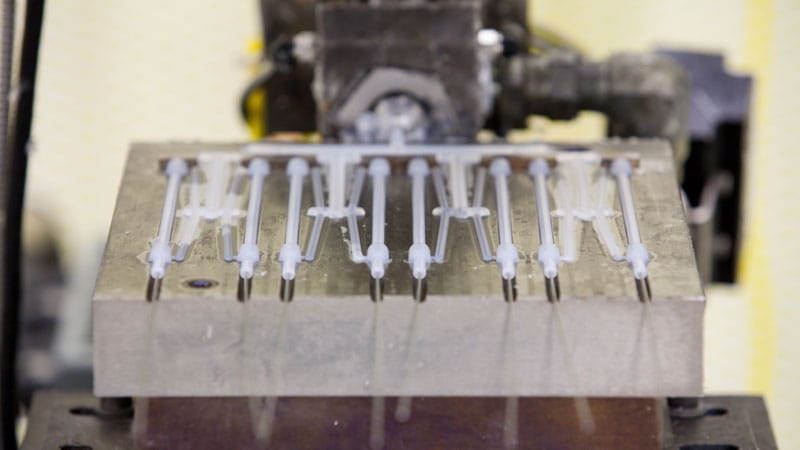

Overmolding is a process in which the finished component of a different material, usually a thermoplastic or metal substrate, is overmolded with LSR in a liquid injection molding process in either a semi-automated or fully automated process. This method of production lends itself to smaller production quantities or to cases where, due to the substrates, an extra step is necessary to apply bonding technology.

Advantages of Overmolding:

- Custom composite products can be produced in combination with thermoplastic, metal, LSR components, as well as with silicone tubing

- Suited for medium size production runs

- Eliminates the risk and cost associated with secondary assembly

- Greater design latitude in applications

- Cost-effective solutions

Fully-bonded components are available in a variety of hard-soft or soft-soft combinations. For components requiring a HCR silicone material, Trelleborg Medical Solutions employs compression, injection, or transfer molding technologies from prototype to multi-cavity serial production tools.

Understanding Molding Complexity to Reduce Device Complexity

Overmolding is a great way to achieve a variety of aesthetics and functionalities in your medical device. Whether its additional colors, grips, flexible components or to enclose one part within another, our team of experts utilize overmolding to produce unique medical devices.

Applications

Overmolding technology has significant advantages in terms of product reliability and total cost of ownership for the customer with applications ranging from hospital and home care equipment and devices, biotechnology, and fluid management.