Single-use Solutions for Fluid Path Systems

Applications

With its BioPharmaPro™ portfolio, Trelleborg Medical Solutions helps biopharmaceutical companies bring innovative, safe, effective and timely biological therapeutics to improve patient outcomes. Our innovative products and materials are designed for use in numerous critical biopharmaceutical processing applications and supports companies from small batch through to serial production.

BioPharmaPro™ Products & Capabilities

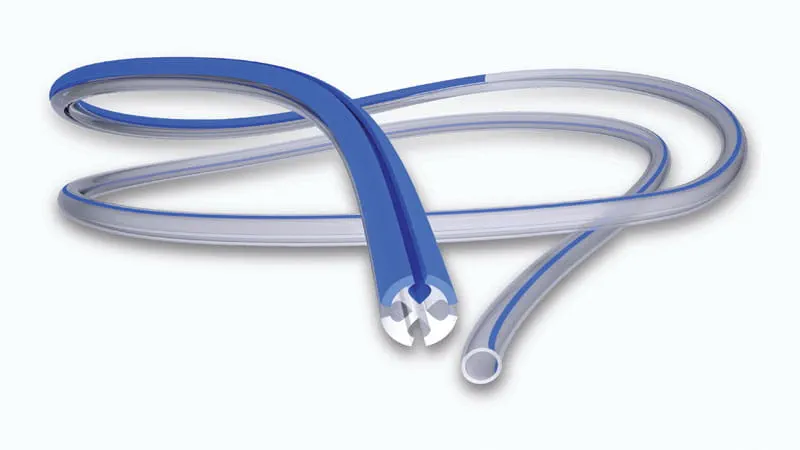

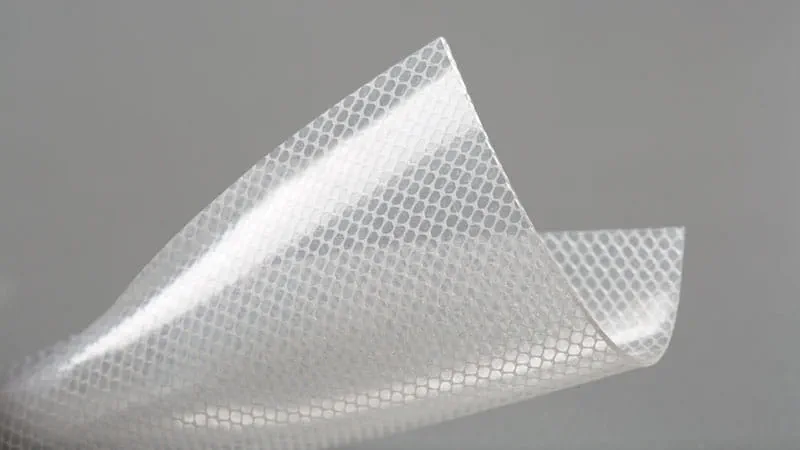

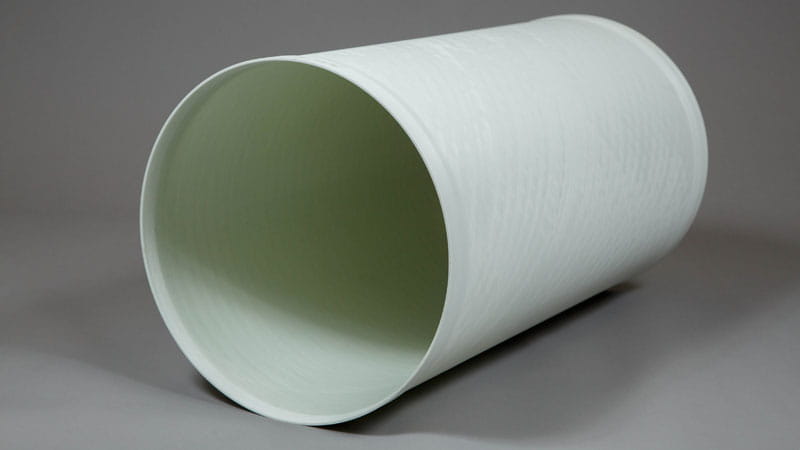

Trelleborg Medical Solutions supports biopharmaceutical companies with a full range of products, from single-use tubing and tubing sets and custom molded parts to full assemblies for filtration or chromatography equipment with advanced composite columns. Our facilities utilize automation, in-house tooling, state-of-the-art processing equipment, and cleanroom production to deliver effective, safe and high-quality products and solutions.

Integrated Solutions

Trelleborg Medical Solutions takes the BioPharmaPro™ product and solution portfolio a step further by delivering value-added fluid path assembly solutions. Bringing new fluid path systems to market faster means we can make an impact on more patients’ lives. At Trelleborg Medical Solutions, our engineers collaborate closely with customers to move as fast as possible through the design, testing and qualification, and commercialization phases of product development, while paying attention to quality and cost. And once our customers’ solutions are on the market, we strive to provide consistent, reliable supply to the agreed upon quality standards.

How our integrated solutions help:

- Custom solutions designed to meet unique customer needs

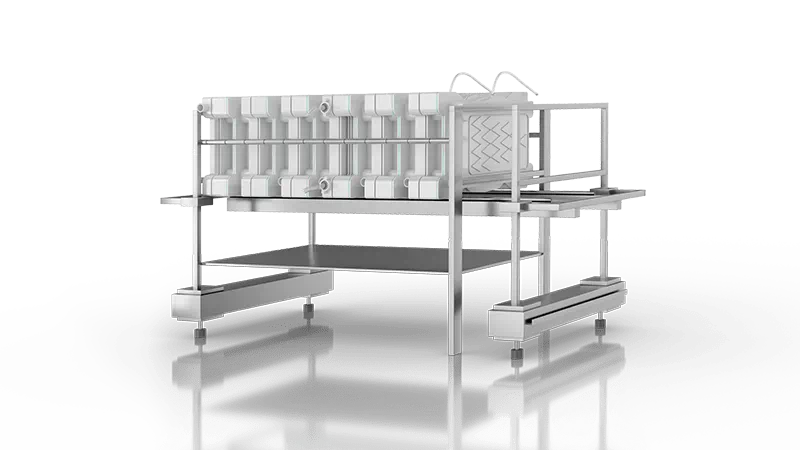

- Integrated solutions range from tubing sets for single-use applications to full equipment assembly, such as chromatography systems

- Support from the earliest development stages through to full serial production

- Our design and material expertise, paired with simulation technology, facilitates the development of the best design for functional solutions

- Reduces risk in the supply chain by consolidating suppliers

- Saves costs through bundled purchasing processes, consolidated audits and shipping and logistics

- Rectifies design and manufacturing issues before a product goes to the market

- In-house assembly and testing in Class 7 and 8 cleanrooms ensure consistent high-quality

- Time and money savings enable you to focus on your core competencies and remain agile for the future