Enabling solutions for challenging applications

Integrate multiple functionalities and meet compliances requirements

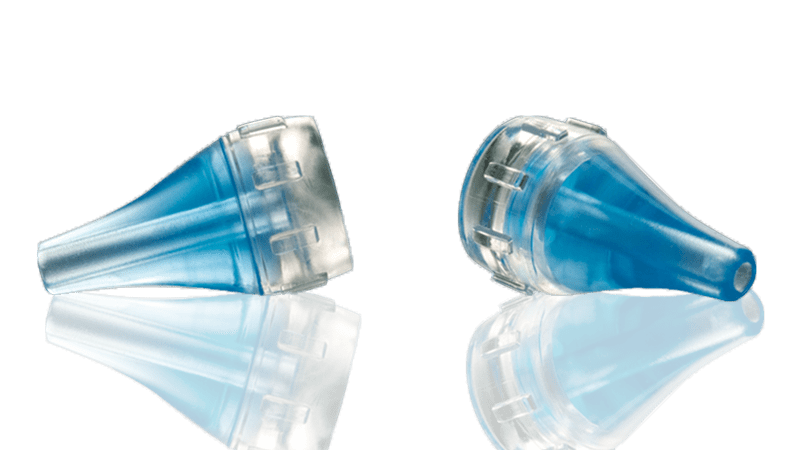

One of our most outstanding capabilities is the simultaneous injection of liquid silicone rubber (LSR) in combination with engineered plastics, Multicomponent LSR Technology. In what is commonly referred to as 2K, 2-shot, multicomponent injection molding or co-injection, our LSR experts employ highly advanced and sophisticated tool and process engineering to develop the most innovation solutions, combining two, three or more individual materials into one fully-bonded, robust component.

Enhanced processing options for more hygienic designs

Trelleborg Medical Solutions is at the forefront of tool, process and automation technology for multicomponent LSR liquid injection molding. In a fully automated and closed loop system, either a combination of thermoplastic and LSR or two dissimilar grades of LSR are co-molded into a bonded component that offers a wealth of benefits in both assembly and function of the finished product.

A second process option for two component parts, suited for lower production runs and commonly applied by Trelleborg Medical Solutions is overmolding. Here, LSR is injected over either a thermoplastic or metal component to create a fully bonded part.