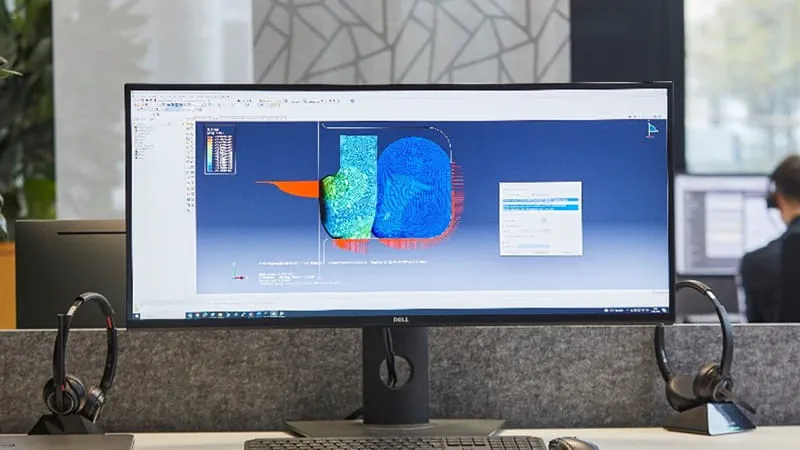

Discover our R&D Capabilities

To meet ever-evolving market needs, we invest continuously in R&D. With a global network of over 15 R&D centers, we specialize in developing innovative products and materials with our customers to create tailored solutions for tomorrow’s challenges.

Extensive Materials and Formulations

Our database includes over 9,000 unique material formulations, designed to tackle even the most complex sealing challenges. These include:

- Elastomers

- Thermoplastics

- Thermosetting polymers

- Composites

Our materials are engineered to perform in highly demanding environments, withstanding extreme temperature ranges and high pressures and demonstrating wide-ranging chemical compatibility, all while adhering to strict industry standards.

Proprietary materials and formulations encompass our

- H2Pro® hydrogen sealing materials

- FoodPro® EPDMs

- Isolast® perfluoroelastomers

- Turcon® PTFE-based materials

- Zurcon® engineered plastics

- Composite bearing materials Turcite®, Orkot®, HiMod®

- Turel® Elastomers

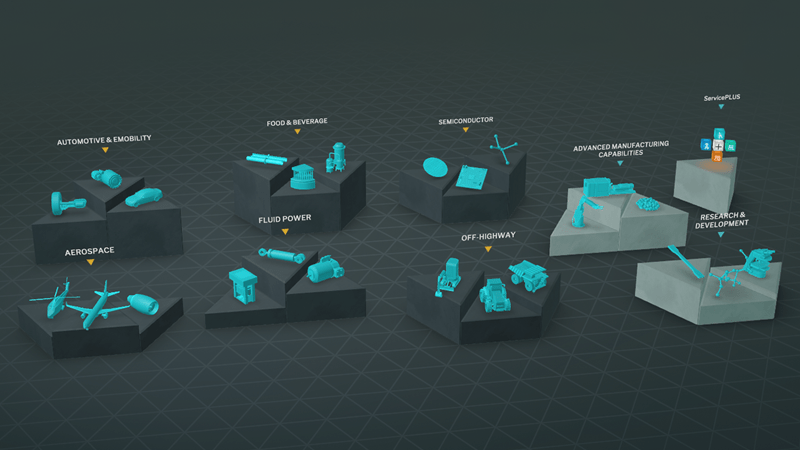

Our Portfolio

Trelleborg Sealing Solutions is equipped with world-class testing, certified to ensure the highest quality standards:

- 200+ test rigs for linear and rotary hydraulic and rotary seals, as well as special test rigs for application-specific customer requirements

- Custom testing incorporating customer hardware

- Certifications: ISO 9000, IATF 16949, ISO 13485, ISO 14000, ISO 17025

- 250+ material testing devices including TGA, DMTA, DMA, DSC, GPC, FT-IR, REM, EDX, tensometer, durometer, rebound equipment and more

- In-house developed products, including AQ-Seal®, Double Delta®, Glyd Ring®, Stepseal®, Variseal®, Wills Rings® and bespoke designs for radial shaft seals.