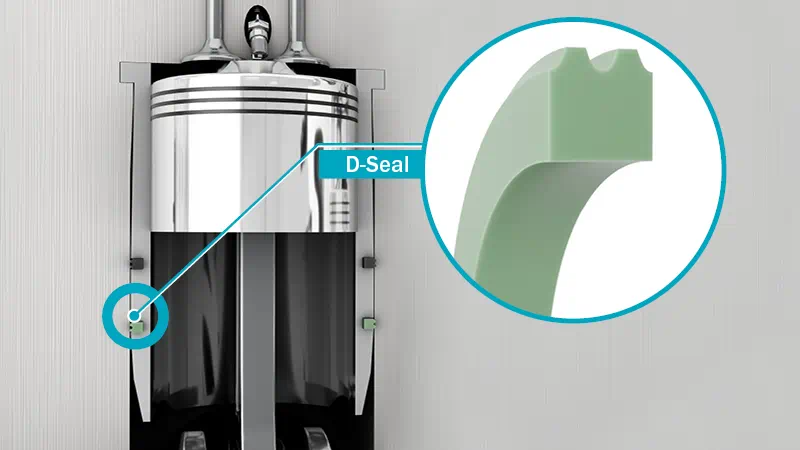

APPLICATION EXAMPLE: D-SEAL FOR CYLINDER LINER

Animation: D-Seal

Combined sealing and damping for critical truck engine and transmission applications

|

Pressure: |

2 to 5 bar |

|

Movement: |

Static |

|

Media: |

Oil, cooling water |

|

Temperature: |

Cooling water (+110 °C) and oil (+120 °C) |

|

Dimensions: |

inner diameter: 120 – 160 mm, cross-section: 3 – 7mm |

|

Materials: |

E7T41 (EPDM) for cooling side and V7T40 (FKM) for oil side, |