Minimizing the risk of spills - all the way down the line

Two key decisions are required when commissioning a safety transfer system.

- Determine whether to fit a Breakaway Coupling (BAC) or Emergency Release Coupling (ERC).

- Confirm the specification of the chosen system.

The Technical Team will advise and assist in confirming the most reliable and efficient option for the specific operation.

A defined separation point within the transfer system

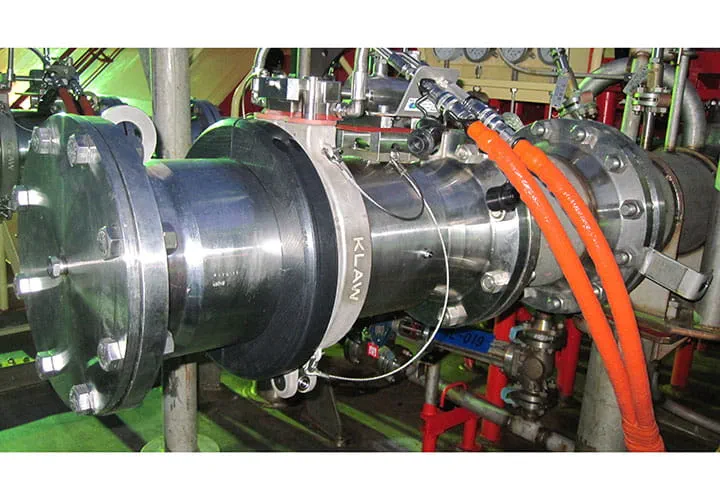

A defined breakaway element within a transfer system allows separation and controlled flow shut-off when stress occurs on the system.

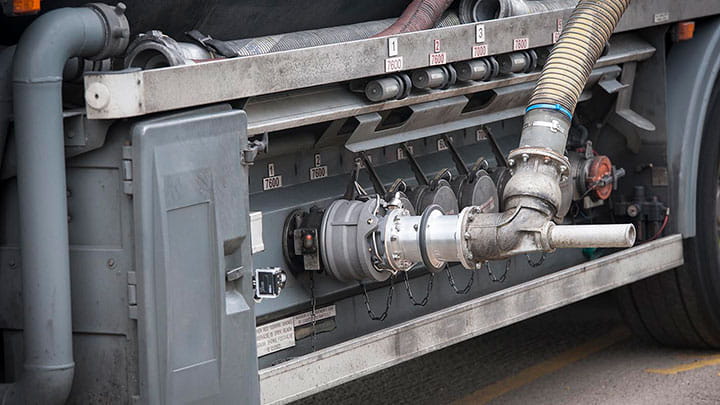

Stress is caused either by pressure surge or inadvertent vehicle movement (vessel, truck, railcar or any other receiving or sending component within the transfer system).

Deciding on a Breakaway Coupling or Emergency Release Coupling

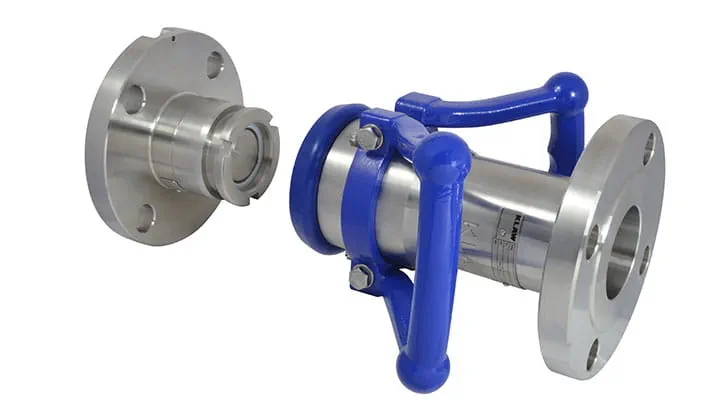

Breakaway Couplings have Breakstuds that hold the two halves of the coupling together. Its purpose is to resist external loads and line pressure up to a pre-determined point. The Coupling then activates when subjected to forces higher than the breakload setting.

Emergency Release Couplings offer a release collar mechanism that resists operating loads via a cable or hydraulic system.

The Dual Release option utilizes both cable and hydraulic methods.

The Emergency Release System is designed to the specific needs of the operation and each option is carefully assessed during specification to ensure the system is correct for the application.

Meeting the expectations of modern and efficient operations

The KLAW range has been designed and developed to deliver reliable transfer solutions that meet the expectations of today’s environment and evolving regulations.

Choosing KLAW means the operator has taken precautions in delivering a safe and reliable product transfer system.

Contact Us

How can we help?