EMEA Local for Local - Building Resilient Supply Chains Together

PFAS Transition

A session exploring the remaining uncertainties around what regulation might mean in practice and the potential timescales for adoption of new rules.

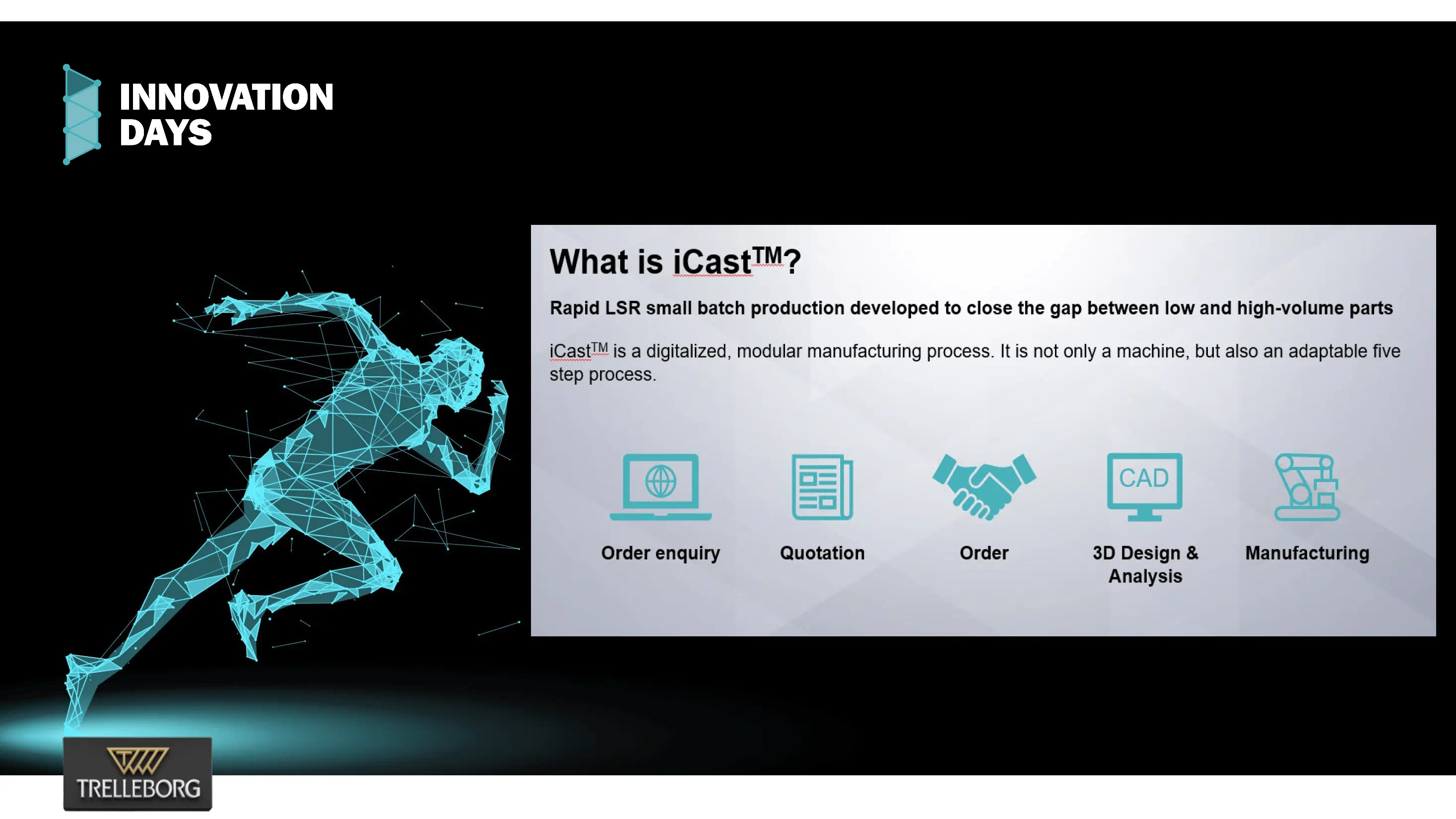

Advanced Manufacturing Technology

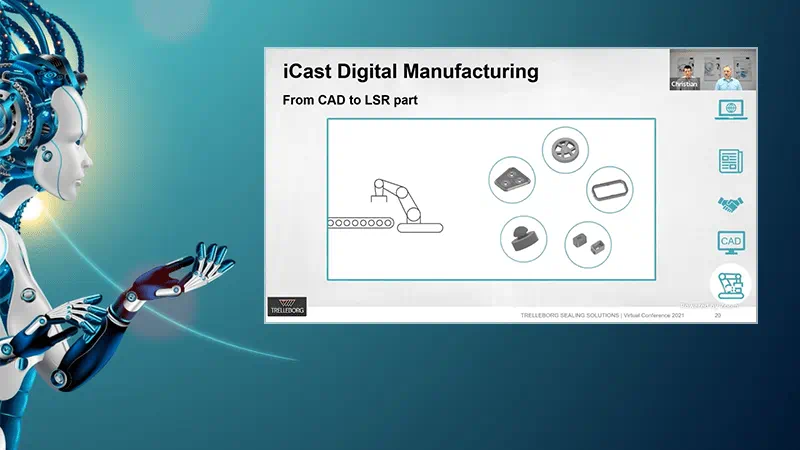

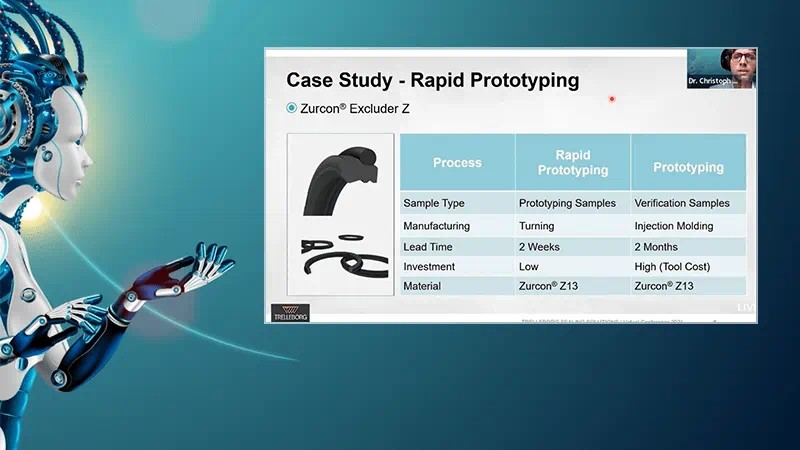

Trelleborg experts Jarno Burkhardt and Christoph Schuele will highlight Trelleborg's in-house additive manufacturing capabilities combined with innovative internal production processes that create added value and support product development as well as small batch production. Trelleborg's innovative iCast™ technology opens the door to a wider range of design options and enables faster time to market and lower development costs.

This session will highlight the manufacturing of Advanced Composites, using Automated Fiber Placement and In-situ consolidation. Trelleborg expert Reid Hislop will also examine industry use cases and discuss the latest solutions using this technology, including Advanced Composite Bearings.

Watch to learn more and see first-hand how these products are produced!

discuss challenges and solutions surrounding the transformation of manufacturing processes with the emergence of Industry 4.5, as priorities shift to sustainability, speed-to-market, and supply chain resilience.

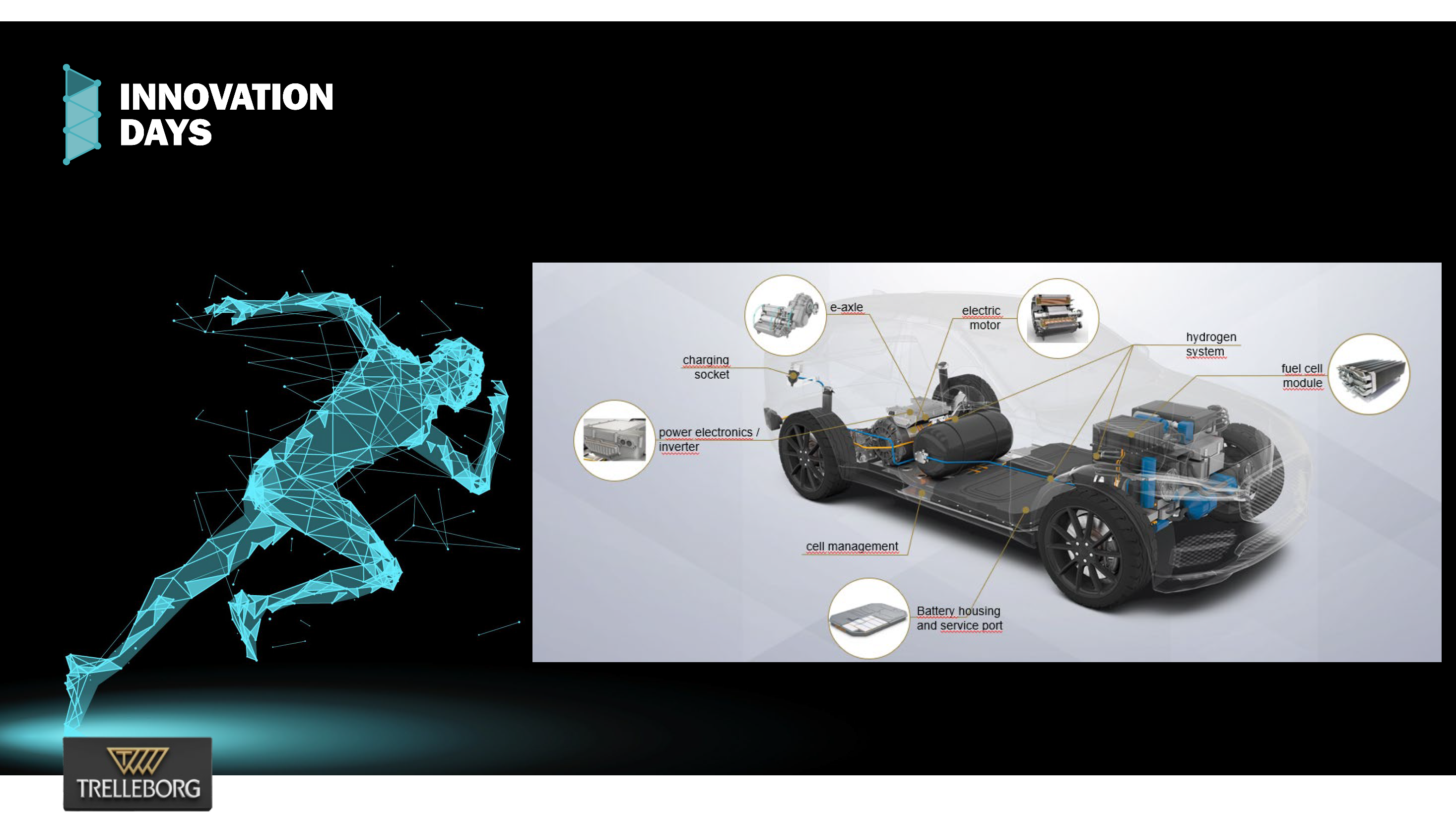

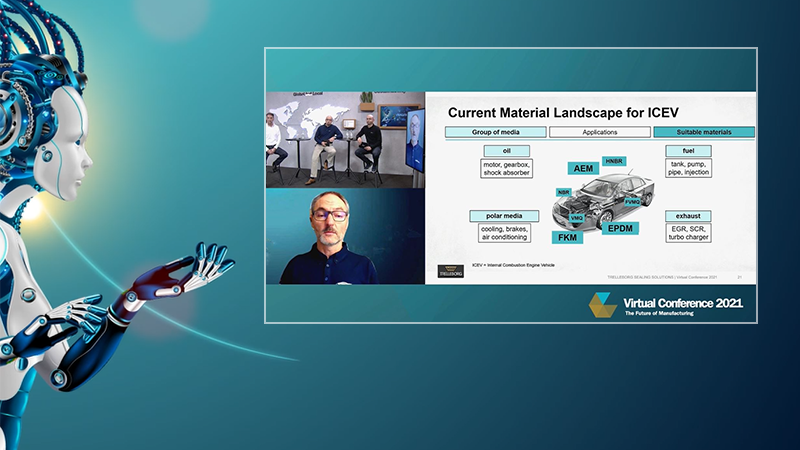

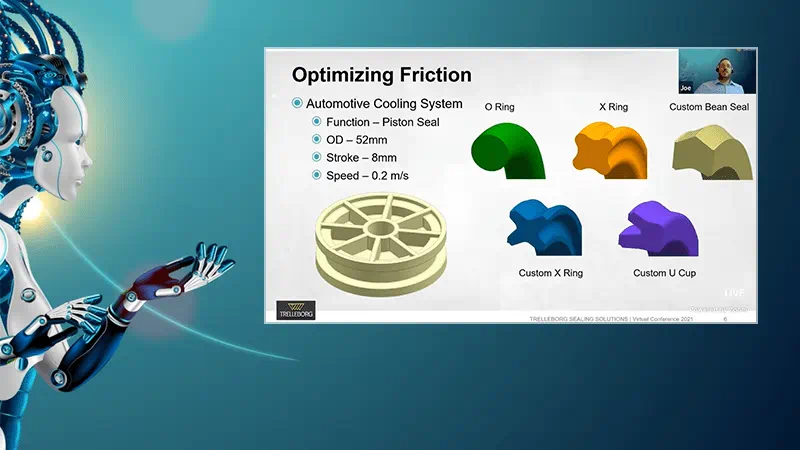

Automotive & eMobility

- Change of customer requirements: Media, Temperatures, Pressures

- New Material portfolio: AEM, FKM, EPDM, LSR

- Examples

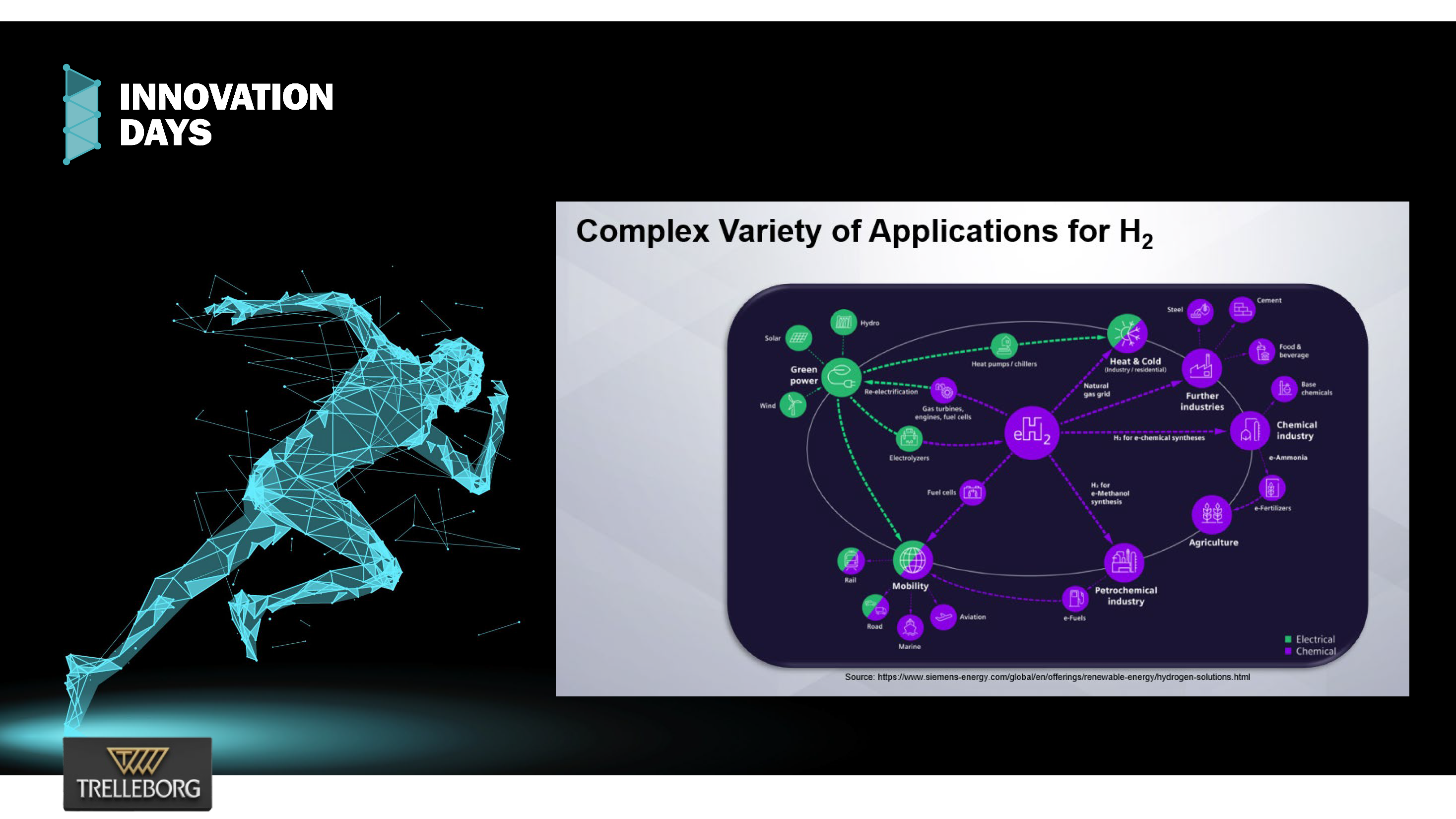

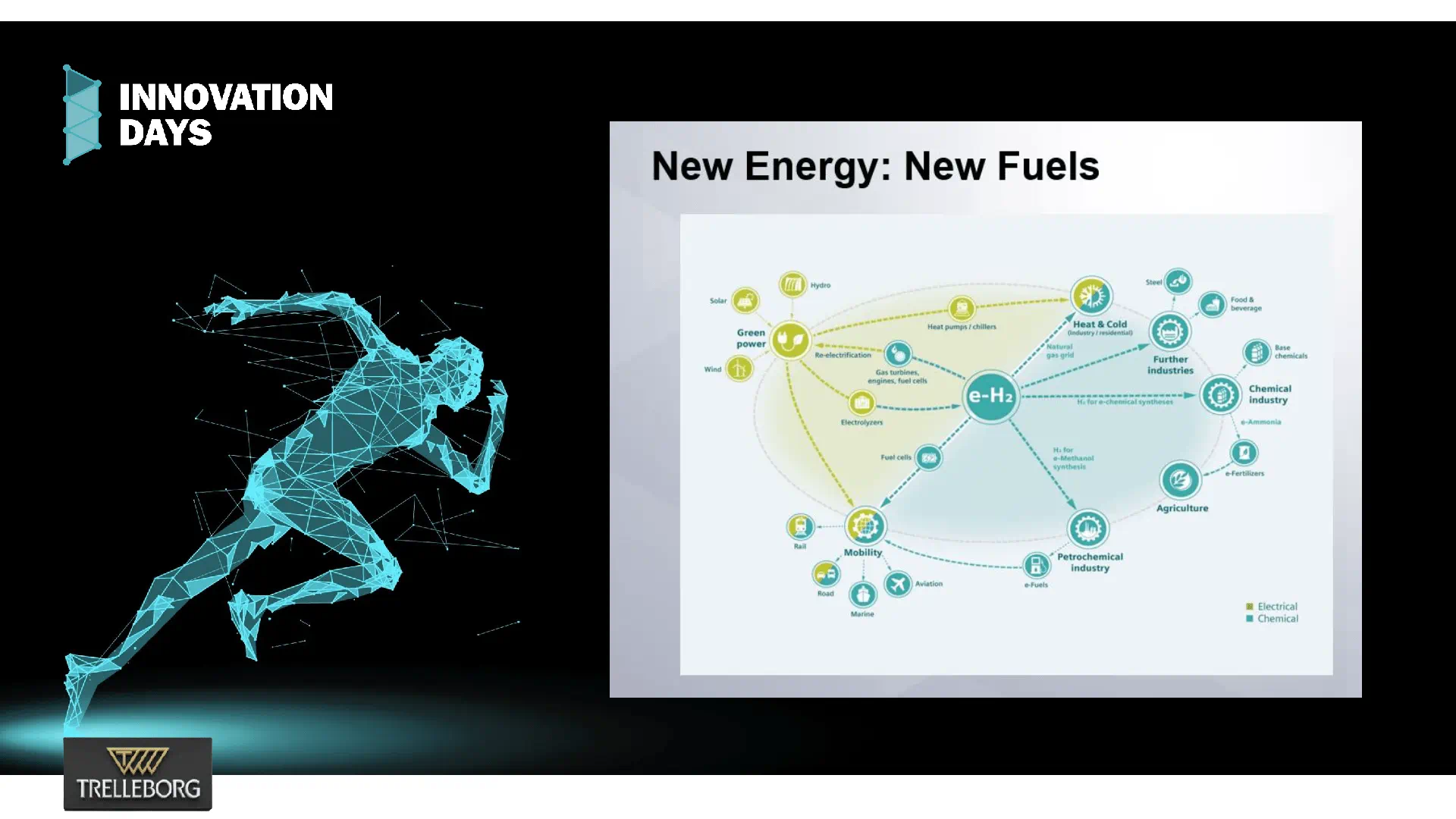

- Hydrogen: the difficult one

- New requirements in eMobility

- Materials and process

- Detection and Solution

- Online and onsite live demonstration

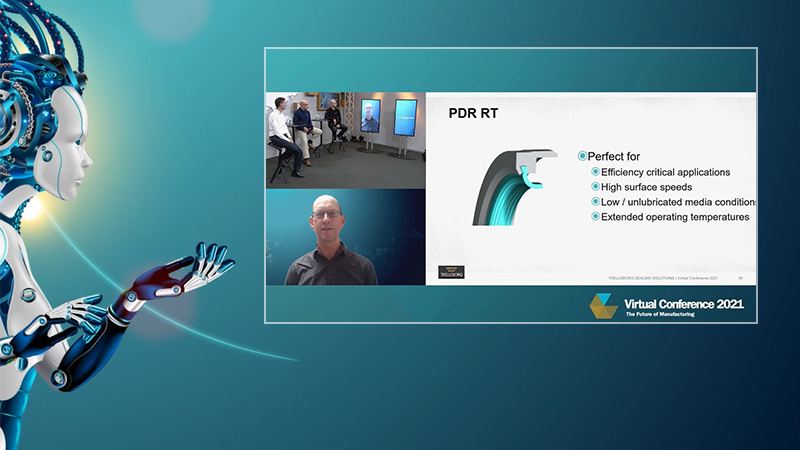

- The unique sealing challenges of the electric drive unit

- Why high-speed rotary seals are necessary for e-axle applications

- Lubrication in transmissions and material compatibility

- Two new HiSpin® seals specially developed for use in eMobility applications

This session covers:

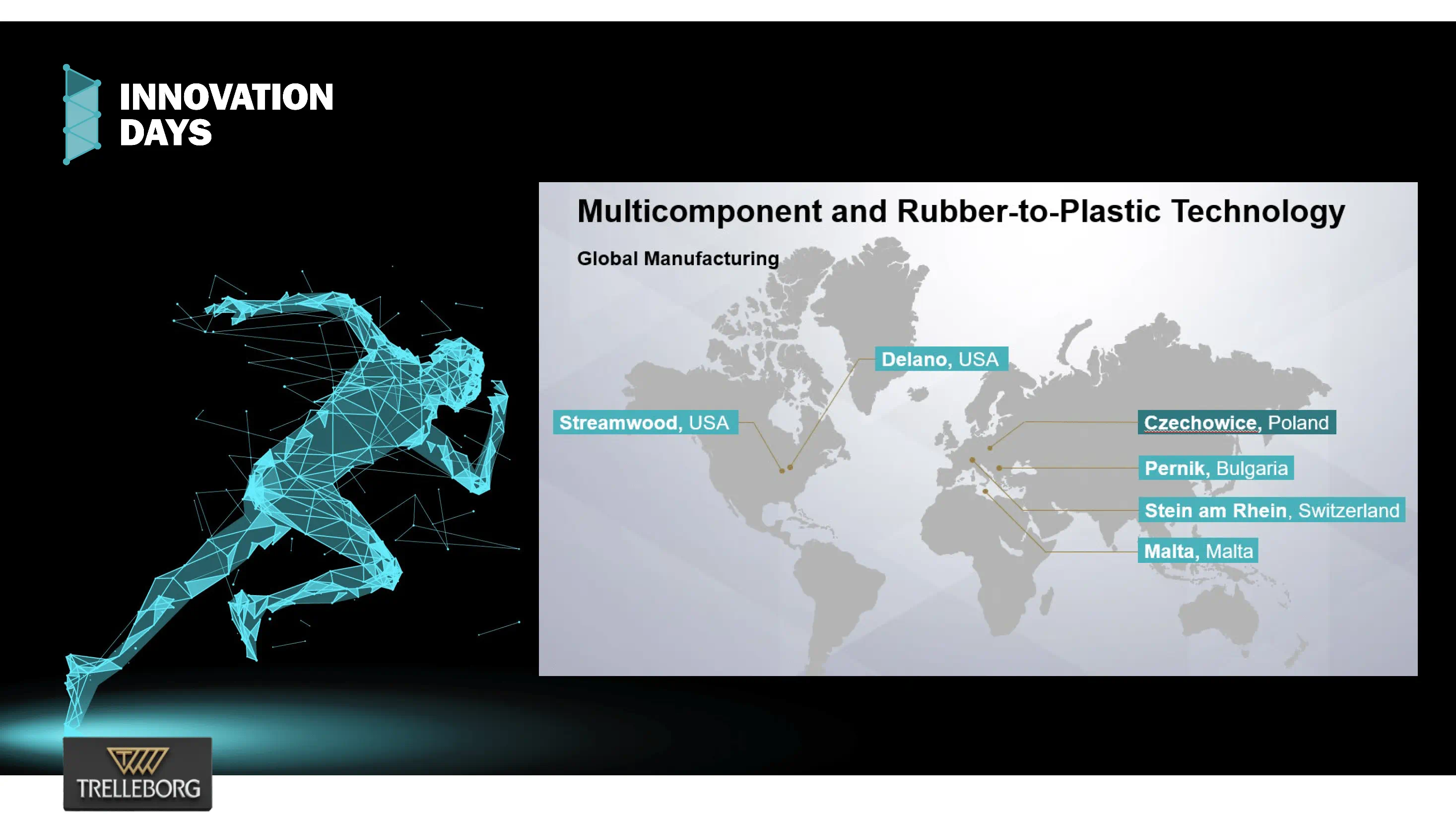

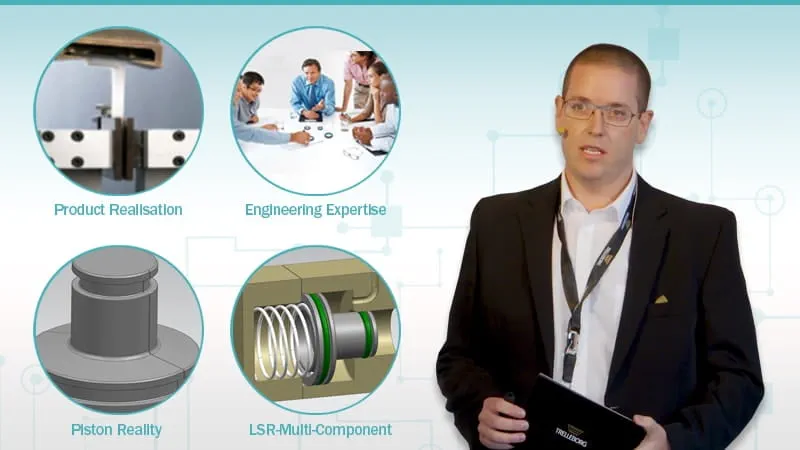

- Material combinations: Thermoplastic, Elastomers, Metal

- Different processes: All-in-one, Overmolding

- Manufacturing advantages

- Sealing and additional features

- Online and onsite live demonstration

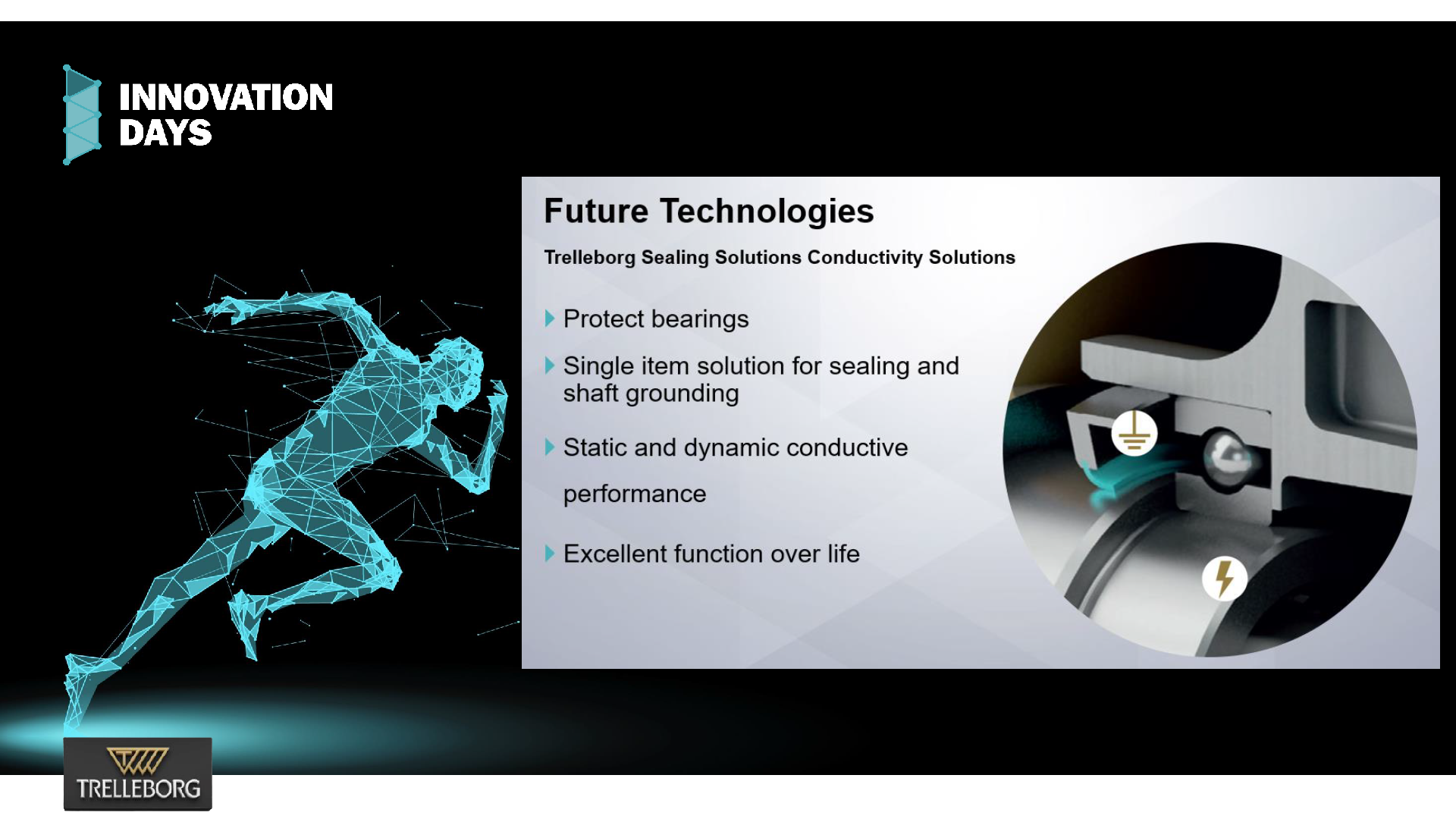

- Target requirements

- Material and design

- Special features: Dry run sealing and Conductivity

Rubore® technology combines the steel or metal part with the rubber sealing component into one single piece. In addition to simplifying the manufacturing process, Rubore® two-in-one products are cost-effective and offer advantages in sealing performance.

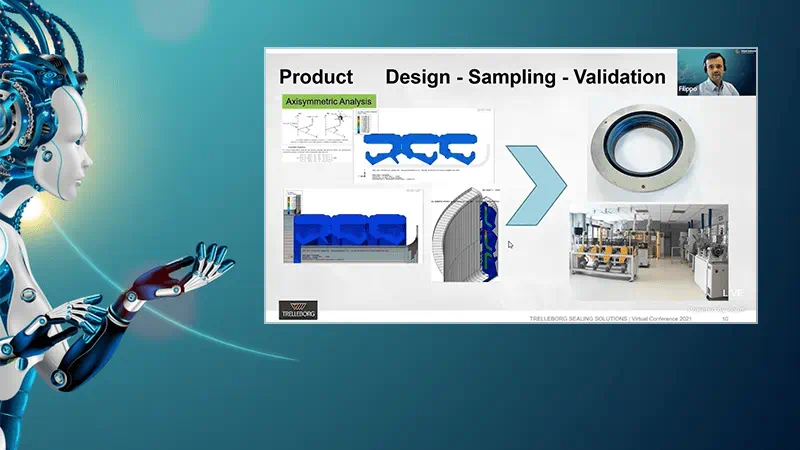

Bringing Products to Market Faster

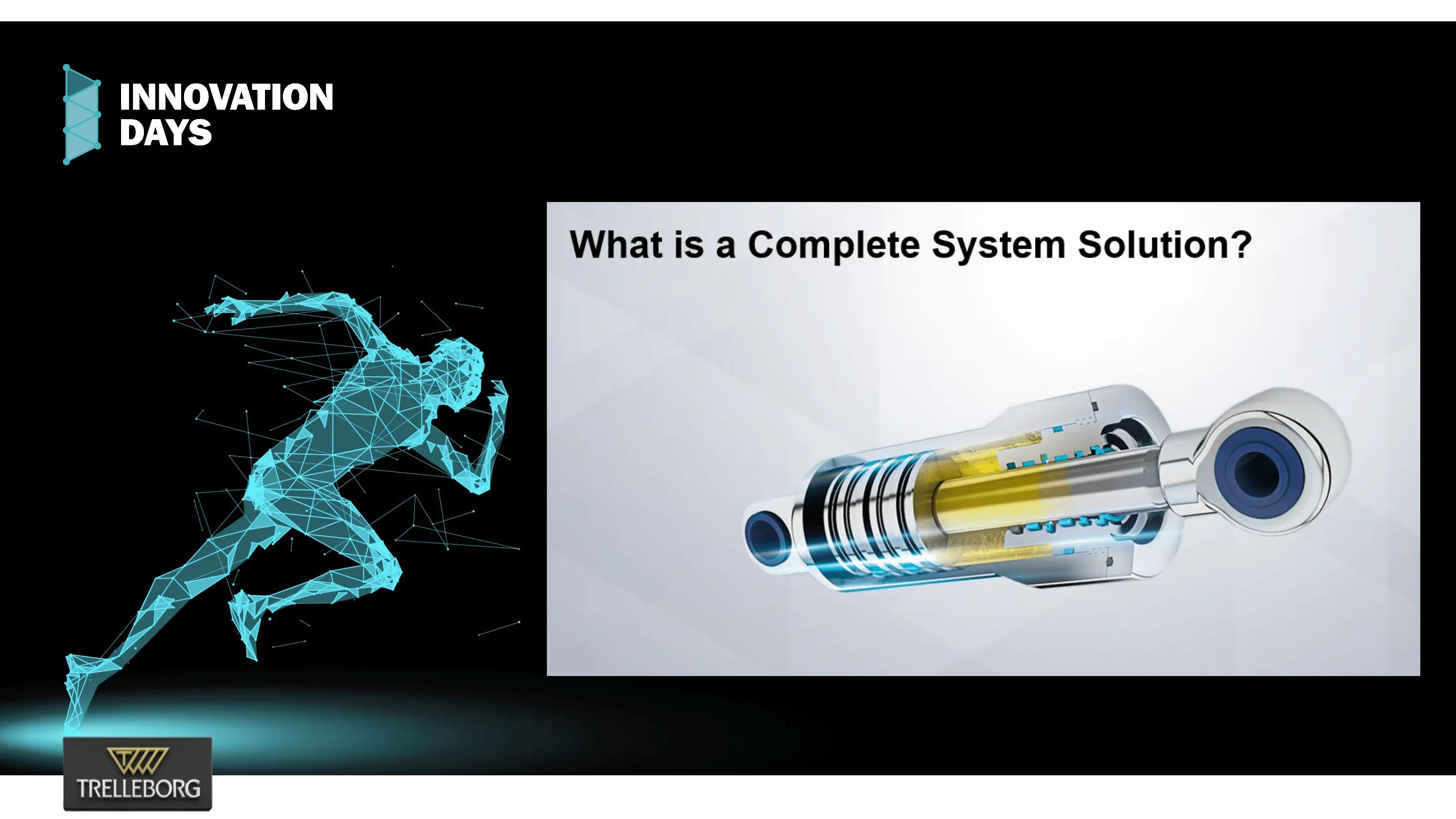

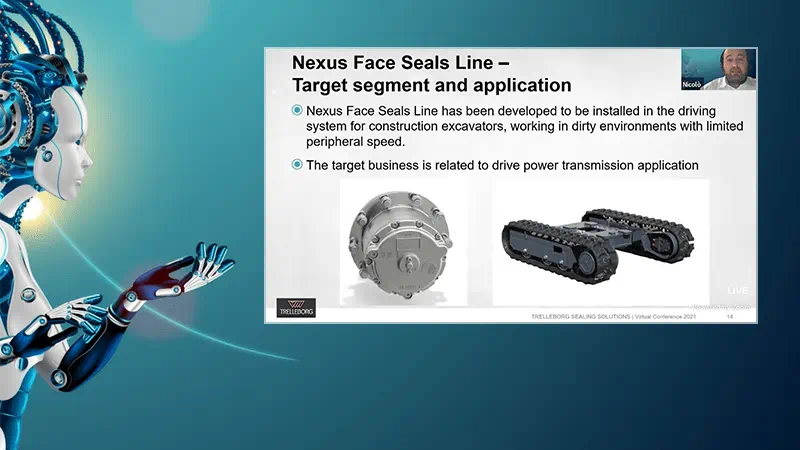

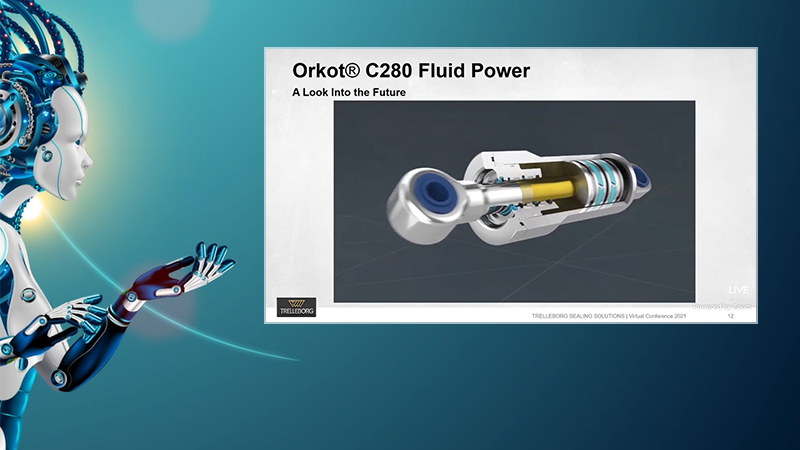

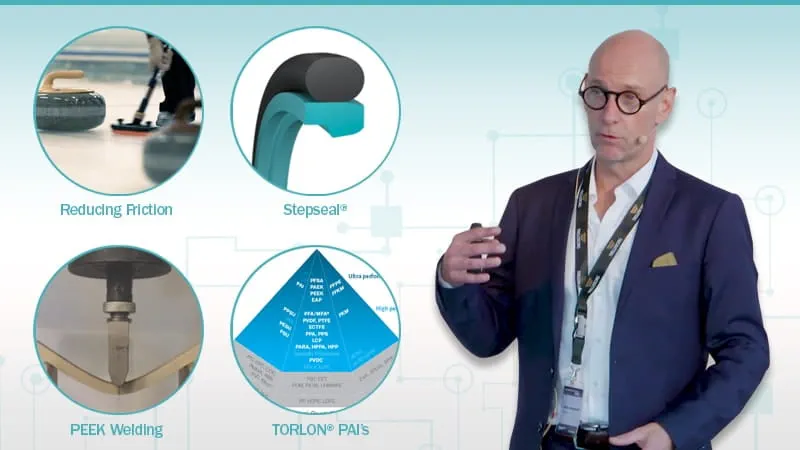

Fluid Power & Off-Highway

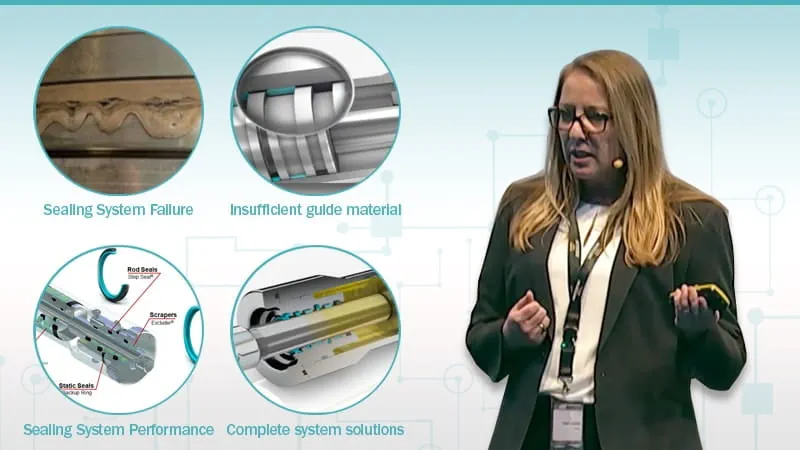

This session will give an overview of the considerations and benefits that lead to such a choice and highlights the most innovative ‘system solutions’ offered today for fluid power applications.

- Sealing system failures

- Sealing system performance and design

- Slydring® product lines, materials and design

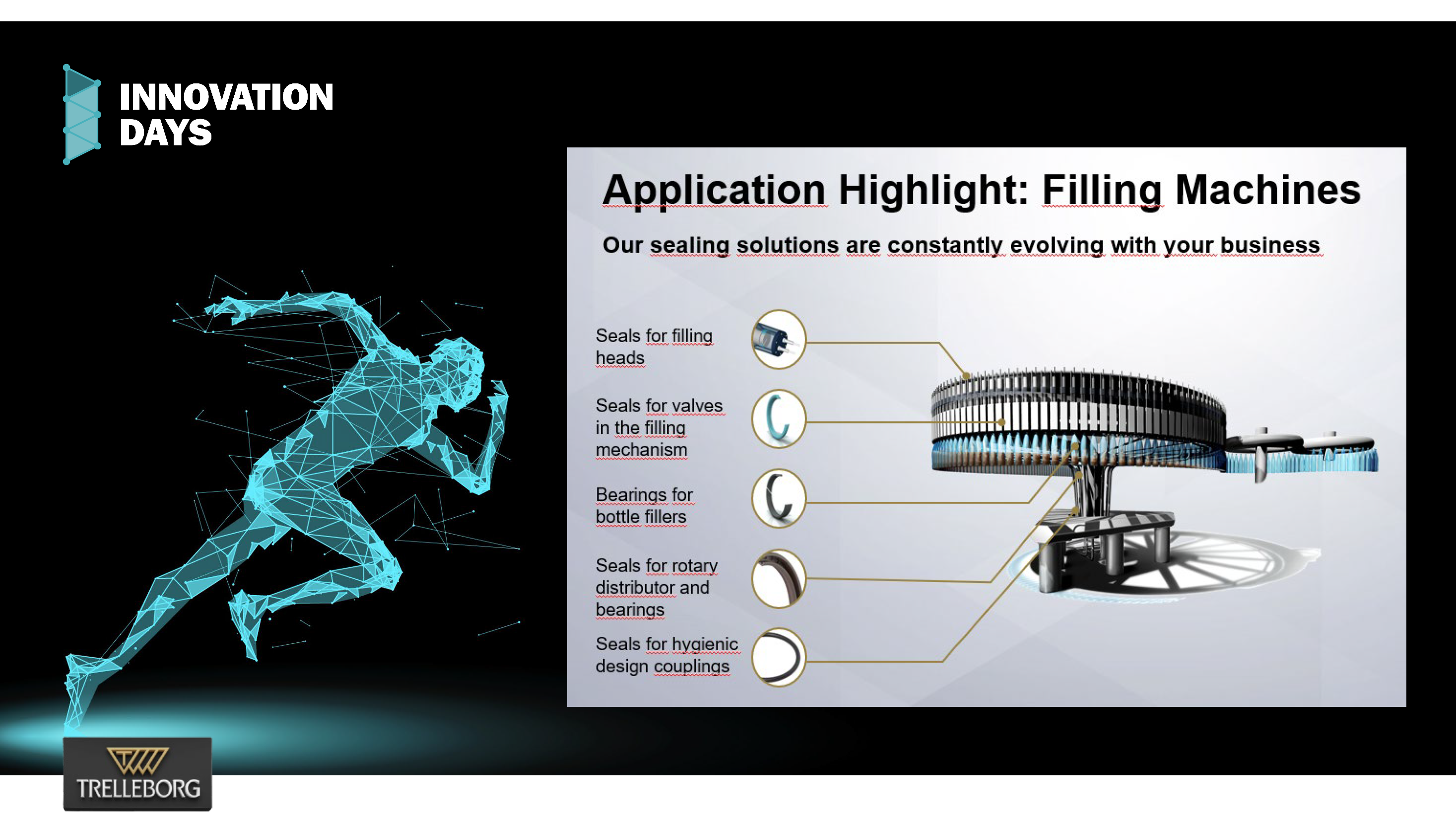

Food, Beverage & Potable Water

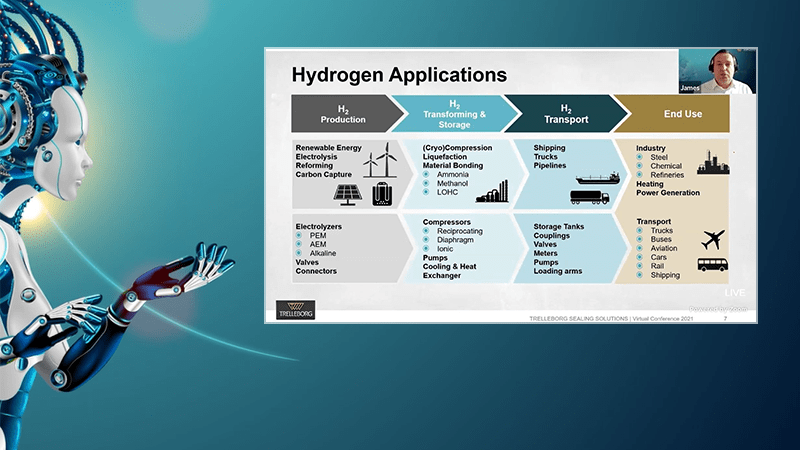

Hydrogen & Energy

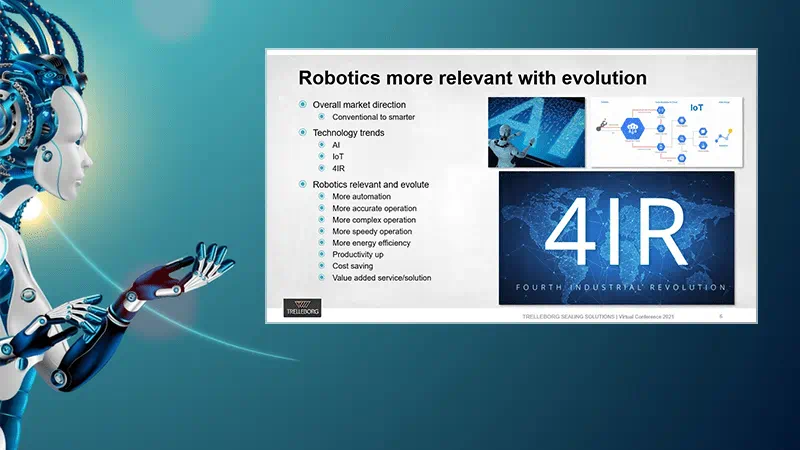

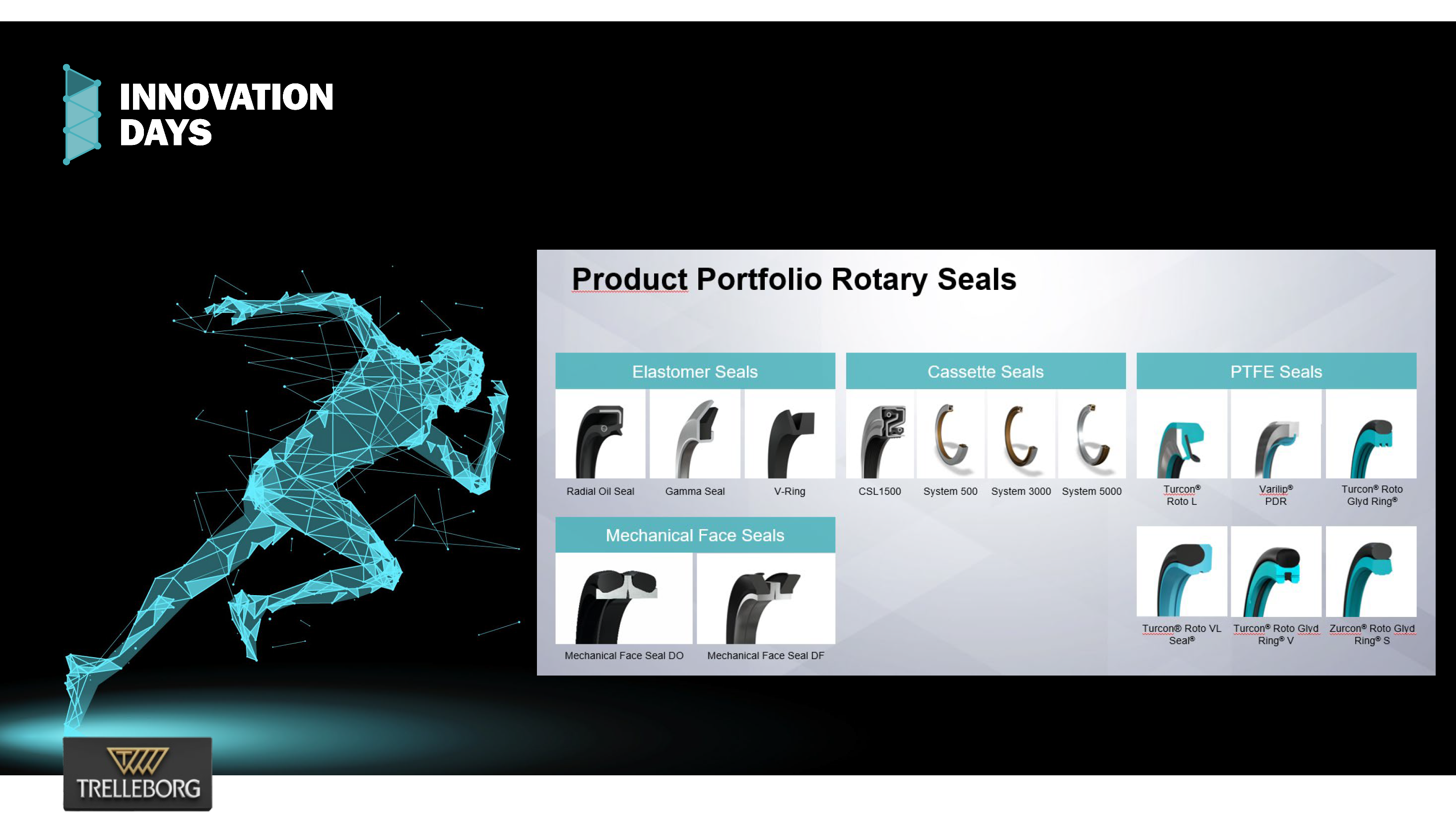

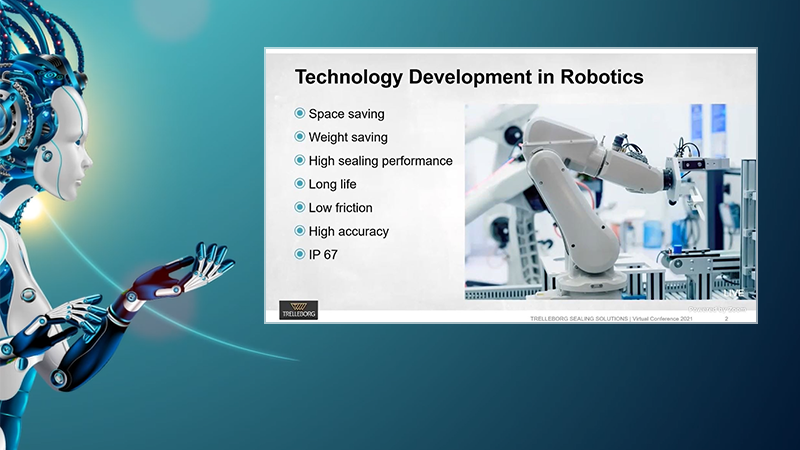

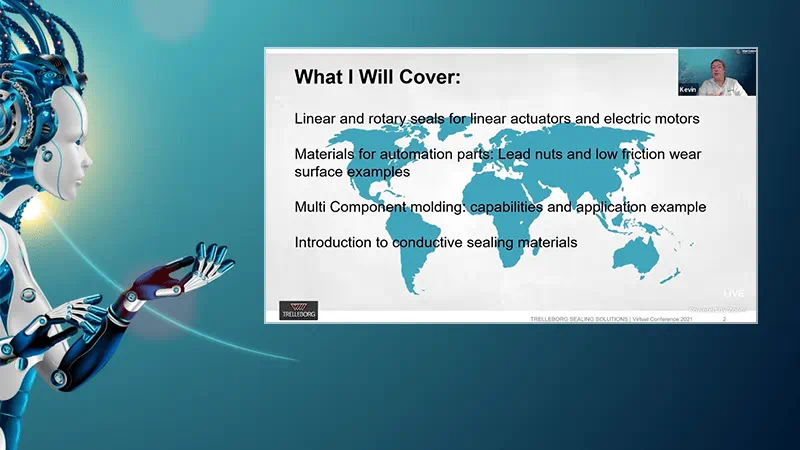

Industrial Automation

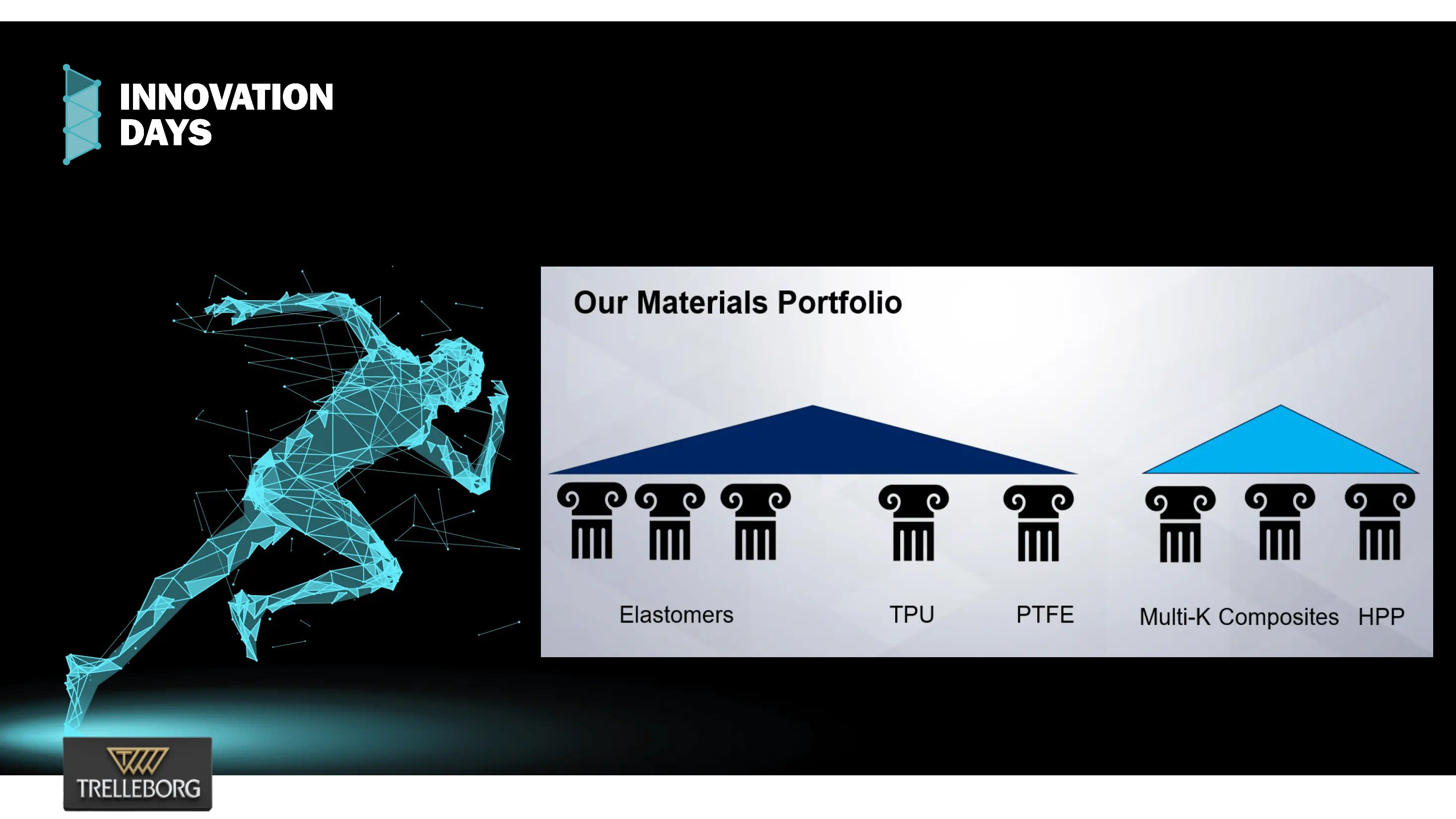

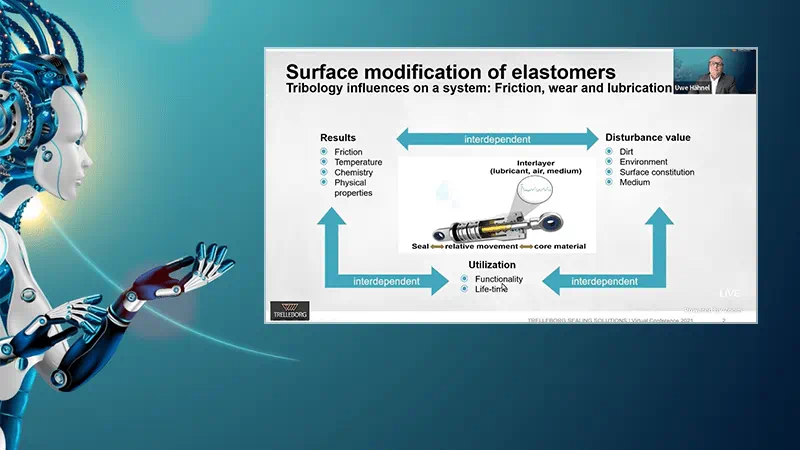

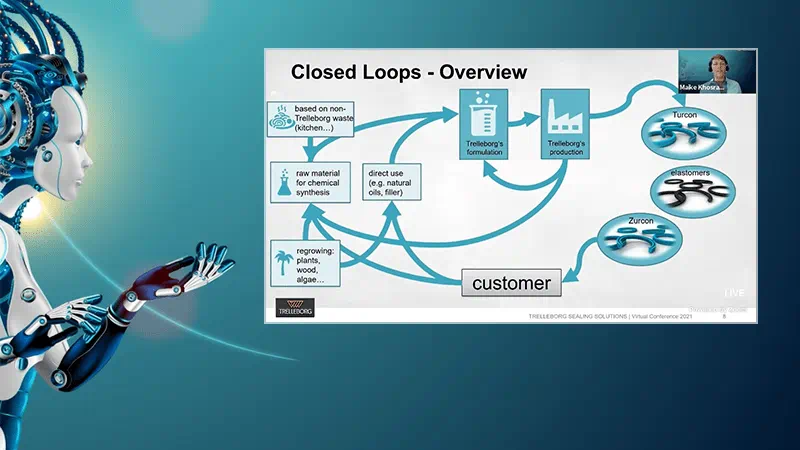

Polymer and Sealing Technology

Research & Development Capabilities

This session covers:

- The stick-slip effect and its prediction by numerical methods

- How to develop stick-slip free sealing systems by using advanced simulations

- Ensure a safe and robust function of hydraulic systems

- How a well-designed “Damping Seal Concept” can prevent stick-slip effectively

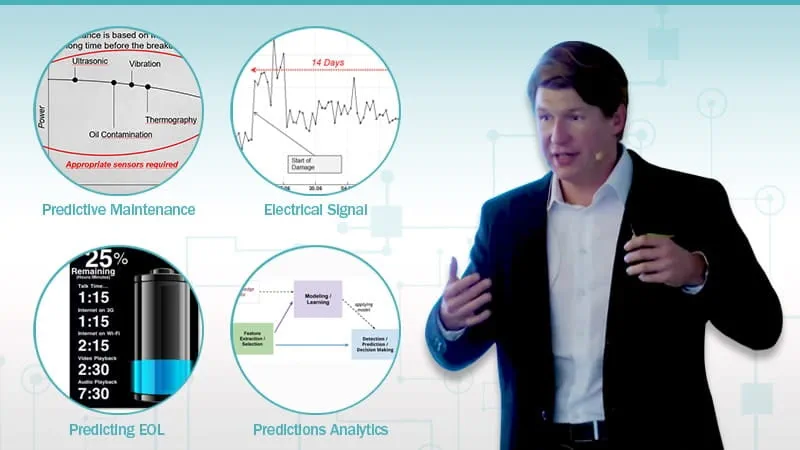

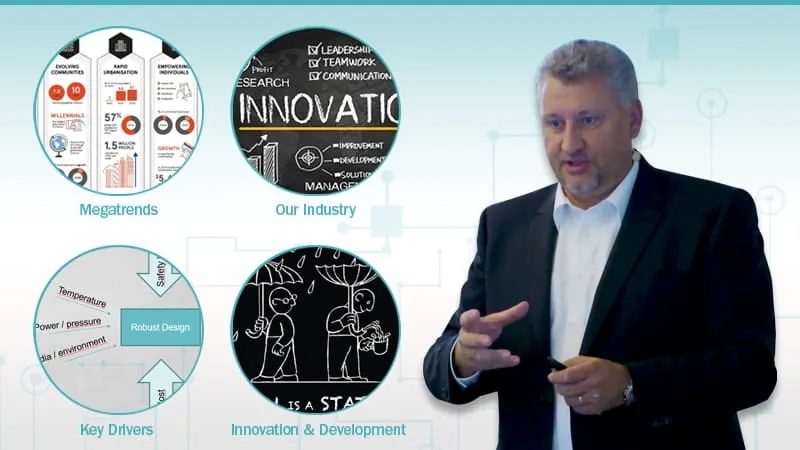

Services, Tools & Trends

- Maintenance strategies

- The industrial Internet of Things (IIoT)

- Smart products, smart services and smart manufacturing in Trelleborg Sealing Solutions

- Increasing technology

- Improving energy efficiency

- Growing digitalization

- Electrification

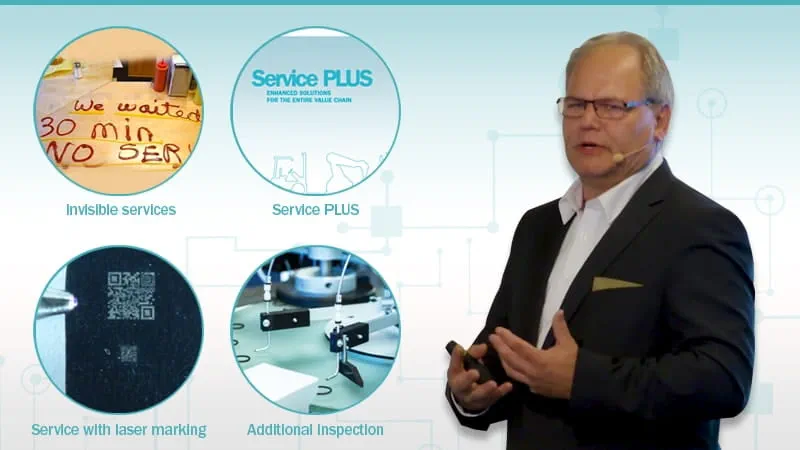

In this presentation Uwe Haehnel, Director Lead Group ServicePLUS & Strategic Projects, talks about the diversity of ServicePLUS and the different stages of service:

- Engineering

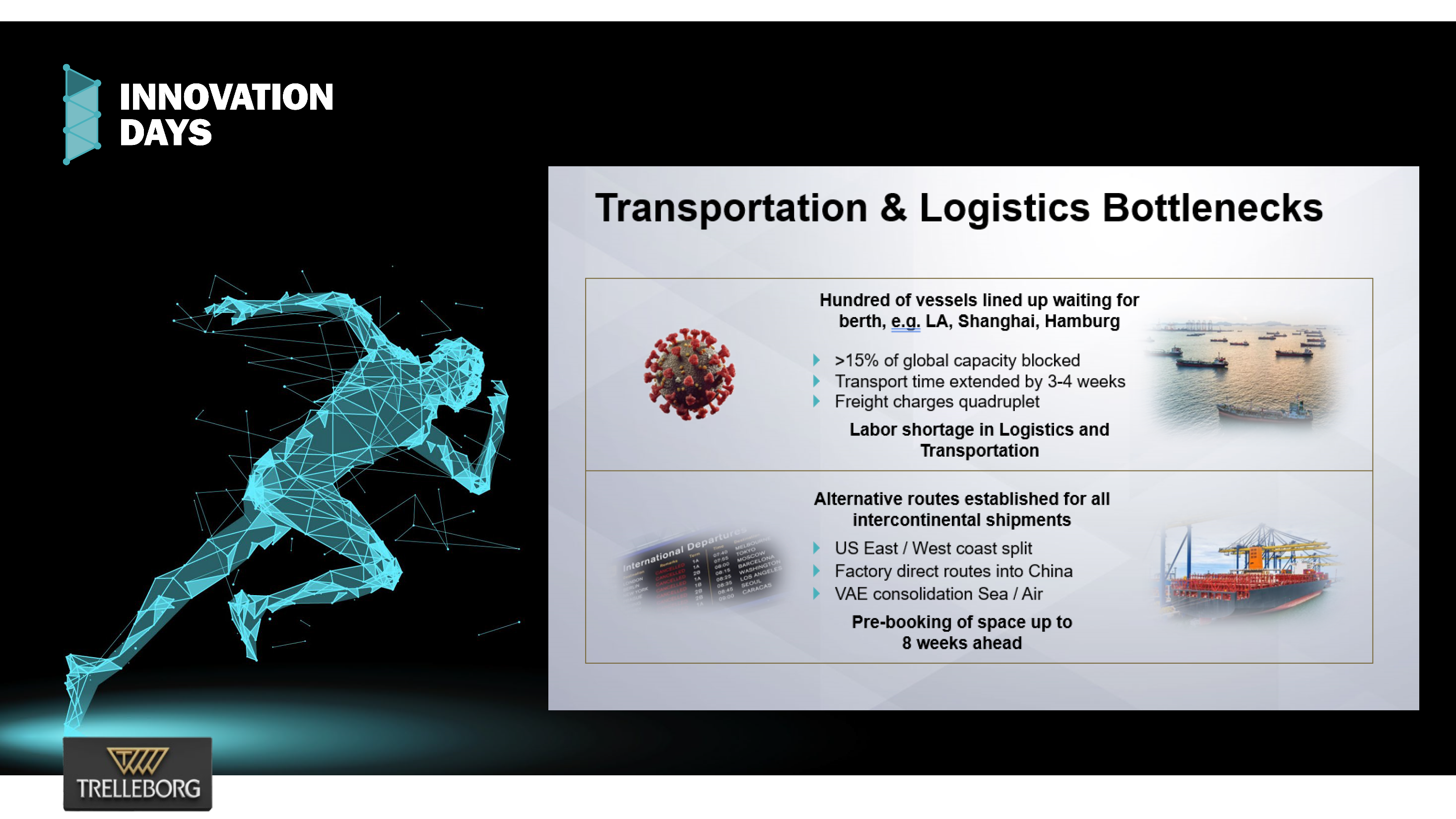

- Logistics

- Manufacturing

- Aftermarket

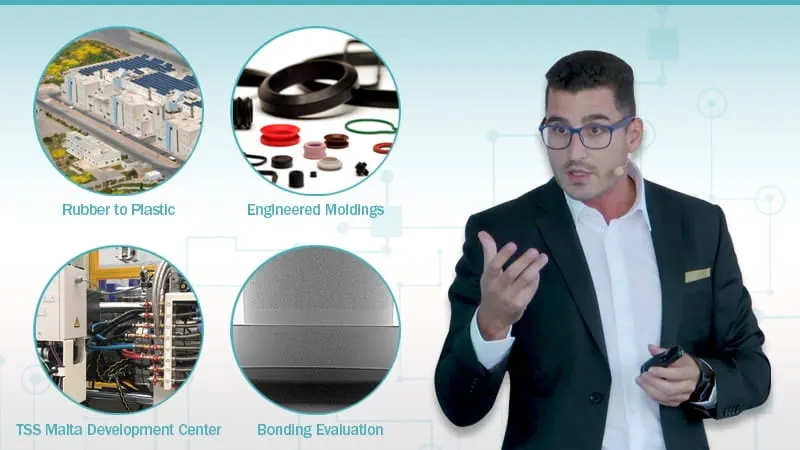

In this presentation, Neal Borg, Product Manager, explains a product that consist of two components – thermoplastic and elastomer which are bonded together.

This session covers:

- Decreased number of assembly steps

- Less handling and part management

- Compact designs and seal configurations

- Variety of target material groups

- Material innovations in high performance thermoplastics

- Performance and media resistance

- Low friction, reliability and lifetime extension

- Functional integration and additional capabilities of materials

Semiconductor

- Learn the new Isolast® PureFab™ FFKM material range, and the unique characteristics of the different materials

- Determine how extensive competitor benchmarking helps identify the best offering and reduces risk when qualifying new materials in highly sensitive environments

- Discover how this material saves time & costs for semiconductor manufacturers