Increasing efficiency, ensuring safety and extending service life are key in the development of innovative high-speed aerospace applications. Our new HiSpin® HS40 and HiSpin® PDR RT seals, specifically designed to perform at high rotational speeds, are the perfect match for cutting-edge solutions. Seals to Optimize Performance at High Rotary Speeds.

Our new family of HiSpin® seals has been developed to meet the ever-growing demand to provide seal integrity at increasingly higher rotational speeds for aerospace applications

Virtual Showroom

HiSpin® PDR RT

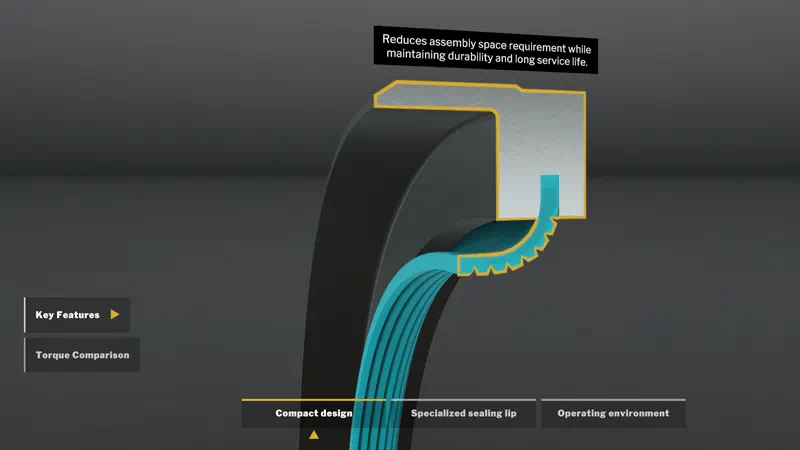

HiSpin® PDR RT optimizes the performance of rotary wing aircraft gearboxes by ensuring essential lubrication and simultaneously preventing leakage at high rotational speeds.

Unique sealing design

The unique design of the sealing lip in the HiSpin® PDR RT ensures effective lubrication on one side of the seal and a dry shaft on the other side. Withstanding extremely high speeds at high temperatures, with minimum friction and minimum power loss, it maintains lubrication within the gearbox while keeping the shaft dry.

The superior high-speed sealing capability of the HiSpin® PDR RT, not only matches the needs for high speed rotary seals in helicopter gearboxes but also provides longer lifetime of the gearbox assembly, resulting in a better service life for the helicopter and ultimately it contributes to increased safety.

Features and Benefits

- Capable of operational surface speeds up to 60 m/s and beyond

- Bi-directional sealing capability

- Compact design reduces assembly space requirement

- Wide temperature range, from -60 °C to +200 °C

- Ability to handle pressure

- Excellent sealing performance with and without lubrication

- Extremely low friction and heat development

- Wide media compatibility

- Negligible shaft wear

- Design optimized for durability and long service life

HiSpin® HS40

With outstanding low friction capabilities, HiSpin® HS40 has been designed to withstand the demanding conditions of high-speed electric aerospace applications, such as electric hoists and electro mechanical actuators.

Innovative design and materials

A unique hydrodynamic feature within the HiSpin® HS40 helps reduce frictional torque. Simultaneously, oil back-pumping leads to improved sealing performance without causing any damage to the shaft.

The seal is manufactured from our proprietary XLT high-performance Fluoroelastomers (FKM) elastomer range. This provides outstanding resistance to extreme engine conditions resulting from high motor speeds and aggressive synthetic fluids. Testing of the new generation XLT compounds has proven that these low temperature FKM grades outperform and extend the temperature performance capability of traditional FKM elastomers.

Features and Benefits

- Works at high speeds up to 40 m/s

- Bi-directional sealing capability

- Compact design to reduce assembly space

- Wide temperature range, from -45 °C to +200 °C due to XLT FKM

- Ability to handle run out

- Excellent sealing performance in different lubricated environments

- Exceptional low frictional torque

- Reduction of heat development

- Proven compatibility with various eMobility transmission and other aggressive fluids

- Negligible shaft wear

- Easy installation

- Cost effective solution

- Available in different outer diameter configurations, e.g. partially rubber covered