Internal Joint Seals by Trelleborg provide long-haul leak protection at Hong Kong International Airport

The challenge: Updating an aging pipe system with minimal disruption to travelers

Hong Kong International Airport is one of the busiest airports in the world, employing 60,000 staff and serving over 53 million passengers in 2024.

The airport adopts an extensive cooling system using purified seawater to keep visitors in the Terminals cool and comfortable in Hong Kong’s subtropical temperatures. Originally installed during the airport’s construction in 1998, this system efficiently utilizes seawater for multiple purposes. After running through the cooling system inside the airport building, the water is collected by a network of segmented underground concrete drainage pipes and recycled as the main source to water the plants within the airport..

In the past 6 years, leakage was detected at certain sections of the drainage pipes. Although the overall quality of the pipe network is good, an inspection in 2019 uncovered that its concrete joints had corroded, with the leakage contaminating the grey water pipes used to maintain plants inside the terminal building.

To prevent damage to the plants from the water’s high salinity, as well as potential future damage to neighboring utilities such as electrical cables and gas pipes, Airport authorities chose Trelleborg to help update their system.

The key challenge of this project was that any upgrade required the air conditioning system to be shut down, limiting the installation window to the system’s routine ‘off’ hours between midnight and 4 am. If the system were shut down any longer, the temperature inside the terminal building would rise to an unacceptable level, causing disruption to customers.

The airport therefore needed a solution that could extend the life of the existing pipe system and be installed within these tight time constraints, while causing minimal disruption to airport travelers.

The solution: Precision reinforcement with internal joint seals

Although airport authorities initially considered a global restoration of the pipe system using the cured-in-place pipe lining (CIPP) method, they ultimately decided against this approach. This is because the suspected leakage points were not in the main body of the pipe – for example, as a result of cracking – but instead were isolated to the jointed areas, which had corroded over time. This made a focused approach more cost-efficient, with the added benefit that it was less disruptive to airport operations.

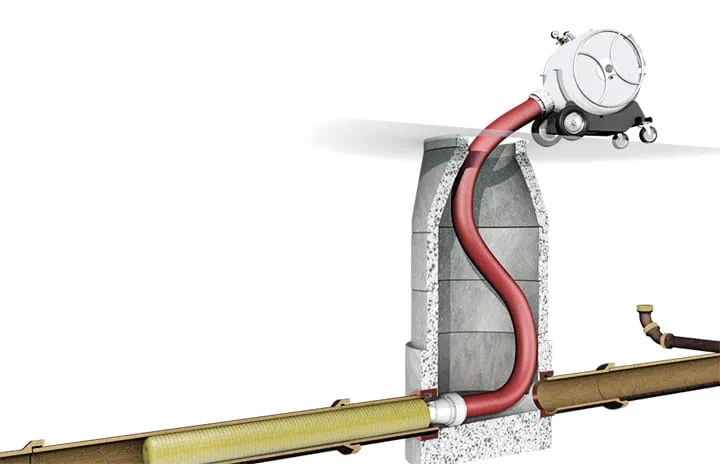

The project team selected Trelleborg’s Internal Joint Seals to address the leaking pipe joints. These seals are designed to bridge the joint using a durable, flexible rubber material, securely joined at the ends with a high-strength vulcanized splice. To ensure a reliable and lasting fit, the seal is then ‘locked’ in place using non-magnetic stainless steel expansion bands.

The key advantage of internal joint seals is their swift installation time, thanks to a unique self-aligning WedgeLock system. These WedgeLock assemblies increase the expansion band diameter and ensure an even distribution of compressive force on the rubber seal without requiring specialized tools or additional process steps.

This allowed the internal joint seals to be installed quickly and efficiently, requiring minimal resources. As a result, the pipes became operational in no time, with only a few additional checks necessary.

The results: Smooth installation for a system that is fit to fly

The installation of Trelleborg’s Internal Joint Seals was swift and effective, with six to eight joint repairs completed in the pipe network per night during the four-hour installation window. This enabled the restoration of one section of pipe each night, delivering the equivalent value of a full-length pipe restoration in a fraction of the time.

The entire project was completed in just one month, with installation taking place three nights per week.

The results were impressive: water leakage stopped, restoring water quality in the grey water pipes and enabling the airport to continue its water-efficient method for maintaining plant life.

The installation also prevents potential future damage to essential infrastructure that could have caused hazards to employees and customers, or even shut down airport operations.

Trelleborg’s solutions did all of this at minimal cost and with minimal disruption to customer experience. As aging infrastructure becomes a growing issue in dense metropolitan areas like Hong Kong, this project is a reminder of the importance of targeted preventative action with precision solutions and high-performance sealing technology.

For more information contact: