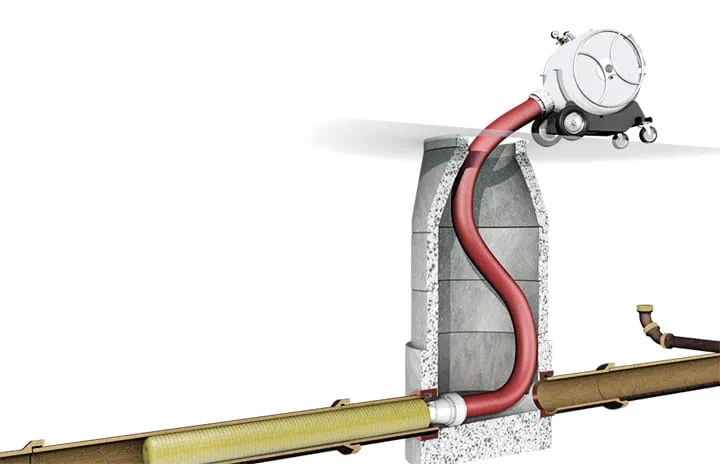

Trelleborg MultiFlex 1D & 3D Liner: The new generation of flexible pipe rehabilitation

The MultiFlex 1D Liner is ideal for nominal diameters from DN 30 to DN 200 and impresses with its final wall thickness of ≥ 3.0 mm. It can handle multiple bends up to 90° and is temperature resistant up to 100 °C when used with a calibration hose.

- Production without transverse seams up to 90 m in length: No transverse seams mean fewer weak points and greater structural integrity

- Final wall thickness ≥ 3.00 mm: Benefit from additional stability and durability, ideal for applications under high pressure and stress conditions

- Curing without calibration hose up to 80 °C: Saves time and effort during installation by curing the liner at higher temperatures

- Optimal impregnability: Ensure even and complete saturation of the liner for optimum adhesion and strength

- Higher burst pressure resistance: Greater safety and load-bearing capacity in critical applications

- Easier expansion: Facilitates installation, especially in tight or hard-to-reach areas

Both liners are compatible with various curing processes – from ambient temperature to hot water and steam to light curing – and can be processed with resin systems such as Trelleborg HC120+ or RayCure UA.

Approved quality – with certainty

The MultiFlex Liner in combination with the HC120+ epoxy resin has been approved by the German Institute for Building Technology (DIBt). The approval number Z-42.3-468 confirms the high quality and safety of the system for use in trenchless pipe rehabilitation. The liner thus meets all requirements for a permanently reliable and standard-compliant rehabilitation solution – even in public areas.

Request a free sample now!

See the quality of the new MultiFlex Liner for yourself. Request your free sample today and experience the next generation of pipe rehabilitation.

For more information contact: