Application Examples

Determining the proper solution for a sealing and bearing application requires expertise in many areas, such as sealing technology, fluid dynamics and material science. Our seasoned engineers are able to provide the specialized expertise you need to balance all of your requirements -- operating performance, service life, cost and logistics.

- Wicket gate/Guide vane bearings

- Wicket gate/Guide vane linkage bearings

- Wicket gate/Guide vane thrust washers

- Turbine main shaft guide bearings

- Turbine main shaft seals

- Trash rake bearings and wear pads

- Lock gate bearings

- Kaplan runner blade bearings

- Kaplan hub seals

- Fish screen bearings and wear pads

- Operating ring vertical and horizontal wear pads

- Valve bearings

- Control gate bearings

- Servo motor bearings

- Servo motor seals

- Eccentric pin bearings

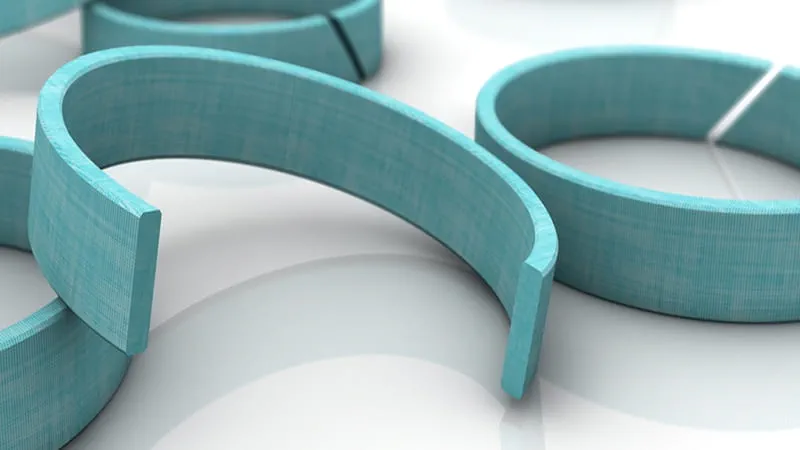

- Segmented mechanical face seal rings

- Fish pump steady bearings

- Spillway gate trunnion bearings

- Spillway gate thrust washers

- Bulkhead wear pads

Power Generation

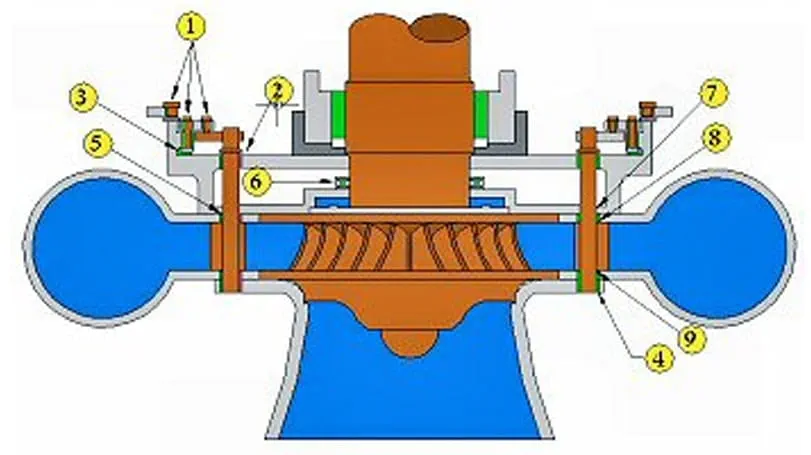

Francis Turbine

Trelleborg Sealing Solutions has been supplying Francis turbine manufacturers and power utility companies with high-performance bearings for many years. Orkot® self-lubricating bearings have replaced the classic greased bronze bearings on both new and refurbished Francis turbines for many years. Orkot® TLMM and Orkot® TXMM self-lubricating bearings eliminate the need for grease, allowing for a cleaner downstream environment. The unique low-friction capacity of Orkot® TXMM allows the material to operate completely dry or in submerged conditions. With excellent mechanical strength and wear resistance, this material performs with virtually no swell in water. Orkot® TLMM and Orkot® TXMM bearings are the proven choice for reliability, long life and superior customer service for Francis turbines.

Typical Operating Environment

Bearings used in Francis turbines are subjected to both wet and dry conditions, heavy side loads, misalignment and impact loads during their normal operating cycles. It is not uncommon to see bearing pressures as high as 2,000psi without the benefits of grease or water lubrication.

Recommended Products

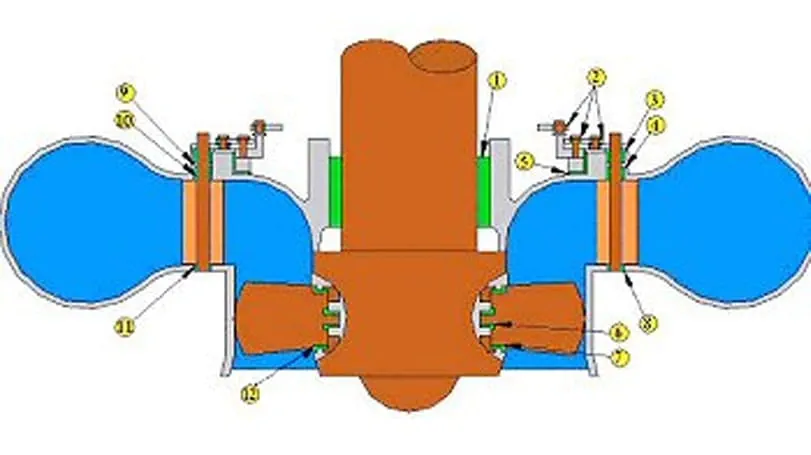

Kaplan Turbine

Trelleborg Sealing Solutions has been supplying Kaplan turbine manufacturers and power utility companies with high-performance bearings for many years. Orkot® self-lubricating bearings have replaced the classic greased bronze bearings on both new and refurbished Kaplan turbines. Orkot® TLMM and Orkot® TXMM self-lubricating bearings eliminate the need for grease, allowing for a cleaner downstream environment. The unique low-friction capacity of Orkot® TXMM allows the material to operate completely dry or in submerged conditions. With excellent mechanical strength and wear resistance, this material performs well with virtually no swell in water. Orkot® TLMM and Orkot® TXMM bearings are the proven choice for reliability, long life and superior customer service for Kaplan turbines.

Typical Operating Environment

Bearings used in Kaplan turbines are subjected to both wet and dry conditons, heavy side loads, misalignment and impact loads during their normal operating cycles. It is not uncommon to see bearing pressures as high as 2,000psi without the benefits of grease or water lubrication.

Recommended Products