Materials

Relying on decades of experience, working with leading equipment manufacturers and end users around the globe, we have developed a portfolio of materials that are ideal for automotive applications. From basic elastomer grades to leading edge high specification compounds; our innovative sealing materials help optimize performance while ensuring sealing integrity.

Specific Material issues in the Automotive Industry

Trend - Issue - Development

Fuel changes - Biofuels are more aggressive to elastomers than traditional fuels - Biofuel resistent materials

Emission regulations become more stringent - Reduction of particulate matter and NOX - Materials for selective catalytic reduction (Adblue)

Greater efficiency required - higher temperature and pressures - Materials to withstand temperature extremes

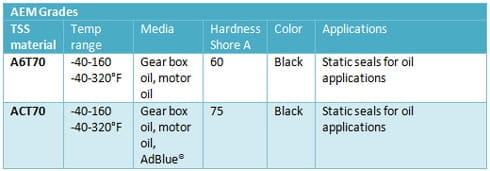

Ethylene Acrylate Rubber (AEM)

AEM is resistant to oil, heat and ozone. It exhibits good resistance to lubricating oils and greases (mineral or synthetic based containing aggressive additives), transmission/power steering fluids, water up to 100°C/212°F and in special circumstances also to dry and wet sour gases and blow-by. The operating temperatures for AEM range from -40°C/-40°F to 160°C/320°F, and for a short period of time up to 190°C/374°F. AEM closes the gap between HNBR and FKM.

The material has:

- Excellent weather & ozone resistance

- Very good heat resistance

- Low compression set

- Resistant to most oils, greases (even with aggressive additives)

- Good low temperature properties

Applications:

Typical applications for AEM are all kind of static seals in contact with oil as it happens in gear boxes, oil pumps, cam covers or others. Special formulations allow the usage in contact with AdBlue®.

Products:

- ECUs for gear boxes, cam cover & oil pan gaskets.

- AdBlue® injectors or QC’s

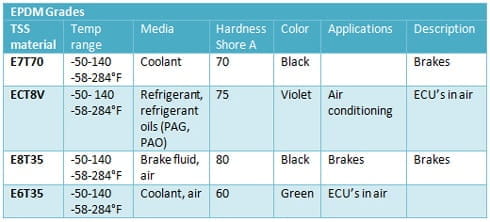

Ethylene Propylene Diene Rubber (EPDM)

Due to the saturated polymer chain, EPDM offers very good heat, ozone and ageing resistance. In addition it also exhibits an excellent low temperature behavior, as well as good insulating properties. The operating temperatures of applications for EPDM range from -45°C/-49°F to 150°C/302°F, and for a short period up to 175°C/347°F (with sulfur-cured types the range is reduced to 130°C/266°F).

The material has:

- Excellent resistance to weather & ozone

- Excellent resistance to phosphate esters

- Good resistance to oxidising chemicals (acids) and brake fluids

- Low swelling in water

- Outstanding resistance to hot water & steam up to 180°C

- Good heat ageing properties

- Excellent low temperature properties

Applications:

EPDM is typically used in applications with brake fluids (based on glycol), as radiator gaskets in contact with coolant, as O-rings in air conditioning to seal refrigerants or just as dust seals.

Products:

O-rings, gaskets

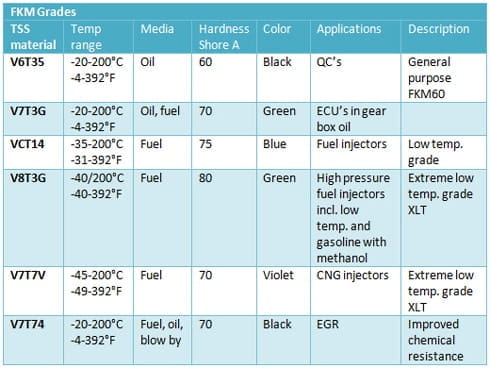

Fluorocarbon Rubber (FKM)

In automotive applications, FKM is known in particular for its very good resistance to fuel, oil and aggressive media as well as the excellent resistance to ozone, weathering and ageing. Depending on structure, fluorine content and used curing system FKM materials can differ with regards to their chemical resistance and cold-flexibility. The operating temperature of FKM ranges from -20°C/-4°F to 200°C/392°F, for a short period of time up to 230°C/446°F.

Special FKM grades can be used down to -45°C/-49°F.

The material has:

- Resistance to oil & grease

- (problematic additives!)

- Very good resistance to fuels

- Excellent heat resistance

- Excellent weather & ozone resistance

- Good acid resistance

Applications:

Due to high chemical resistance and low swelling in fuels (especially when containing ethanol and methanol) FKM can typically be found in the complete fuel supply chain (fuel injectors, quick connectors, high pressure pumps, etc.). Additionally, gaskets in ECUs for gear boxes are also a field of application.

Products:

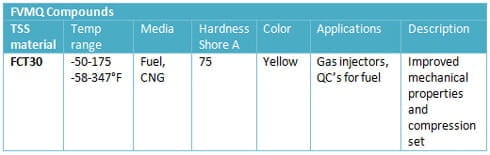

Fluorosilicone (FVMQ)

FVMQ (Fluorosilicone) has a good heat resistance, very good low temperature flexibility and excellent resistance to weather, ozone and UV rays. FVMQ offers a significantly better chemical resistance than standard silicones (VMQ) especially when used with hydrocarbons, aromatic mineral oils and fuels. Compared to VMQ the temperature range is slightly reduced from -50°C/-58°F to 180°C/356°F.

The material has:

- Very good chemical resistance

- Very good resistance to fuel and oil

Applications:

The main applications for this material are injectors for CNG and quick connectors for fuel rails

Products:

Mainly O-rings, membranes

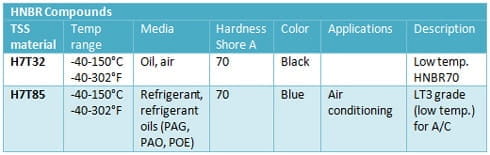

Hydrogenated Nitrile Butadiene Rubber (HNBR)

HNBR is made via selective hydrogenation of the NBR butadiene groups which improves the temperature and ozone resistance considerably. Due to the polymer structure, HNBR offers both resistance to polar and nonpolar media. The selection for dedicated automotive applications depends on the ACN content which can range from 18% to 50% (this influences the swelling in oil), as well as on the degree of saturation (this influences the heat resistance). HNBR offers extraordinarily good mechanical properties and abrasion resistance. The operating temperature ranges, when in contact with mineral oils and greases from -30°C/-22°F to 140°C/284°F and for a short period of time up to +160°C/320°F. Special types can be used down to -40°C/-40°F.

The material has:

- Superior heat resistance up to 140°C

- Superior environmental resistance

- Improved resistance to polar fluids

Applications:

Due to the good abrasion resistance and oil resistance, the main applications are actuator seals for gear box applications. In addition, HNBR is often used in air conditioning applications

Products:

Lip seals, O-rings, static seals

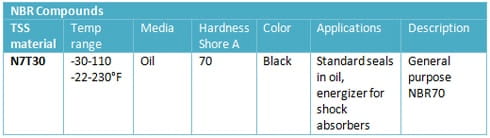

Nitrile Butadiene Rubber (NBR)

As with HNBR the properties of Nitrile Rubber (NBR) depend mainly on the ACN content which can range from 18% to 50%. In general NBR shows pretty good mechanical properties. Due to the unsaturated polymer chain the maximum operating temperature is limited to +100°C/212°F (for a short period of time up to 120°C/248°F), while the minimum temperature can go down to -30°C/-22°F (suitable formulated NBR can be used down to -50°C/-58).

The material has:

- Good oil resistance

- Moderate heat resistance, 125°C in oil / 100°C in air

- High tensile & tear strength

- Good abrasion resistance

- Non expensive

Applications:

NBR is widely used in contact with mineral based oils and greases as energizers for PTFE seals or in shock absorbers due to the excellent abrasion resistance.

Products:

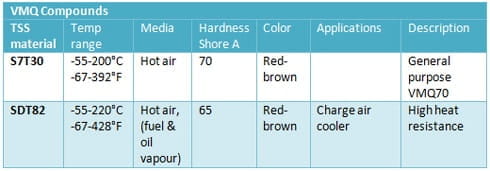

Silicone (VMQ)

Due to the different polymer composition VMQ (Silicone) shows excellent heat resistance combined with an extraordinary cold flexibility and a very good resistance to weather, ozone and UV rays. Specific formulations are resistant to aliphatic engine/gear oils and water up to 100°C/212°F. The suitable operating temperature ranges from -60°C/-76°F to 200°C/392°F (special grades up to 220°C/428°F).

The material has:

- Very good low and high temperature properties

- Excellent resistance to weather and ozone

Applications

Due to their heat resistance they are used as heat exchanger gaskets

Products:

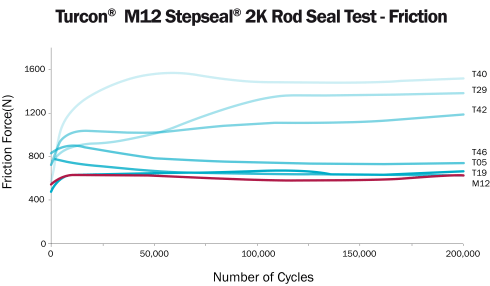

Turcon® M12: High performance PTFE

Turcon® M12 from Trelleborg Sealing Solutions is a PTFE based sealing material whose performance is unrivalled in key hydraulic sealing characteristics, such as friction, wear and high pressure operation.

Comprehensive testing has shown that no other PTFE based material can give such universally exceptional performance.

Turcon® M12 is now recommended by Trelleborg Sealing Solutions as the material of choice for a wide variety of automotive hydraulic applications including:

- Cylinders for convertibles

- Shock absorbers

- Active body control

- Avoids scratching on counter surfaces

- Low friction gives smooth movement

- Withstands high system pressure

- Outstanding wear resistance

- Good resistance to extrusion

- Resistant to virtually all media including a broad range of lubricants

- Extends seal life

The graph shows the friction characteristics from two seals placed opposite from each other in the same test chamber. The friction force of the Turcon® M12 is around half the value of the friction results for T40. These test results prove that Turcon® M12 has the lowest and most consistent friction characteristics.

XLT Materials

The XLT family is the latest innovative series of low temperature peroxide-cured fluoroelastomer grades from Trelleborg Sealing Solutions. XLT has been designed to specifically meet the challenging demands of automotive applications and is useful within high pressure direct injection applications.

Automotive trends affecting elastomer sealing materials

- Fuel changes – Materials need to be resistant to bio-fuel that are more aggressive to elastomers than traditional fuels.

- Stringent emission regulations – Seals must withstand different media, such as Adblue, used for selective catalytic reduction.

- Greater efficiency – Materials must be resistant to a wider temperature range and pressure extremes.

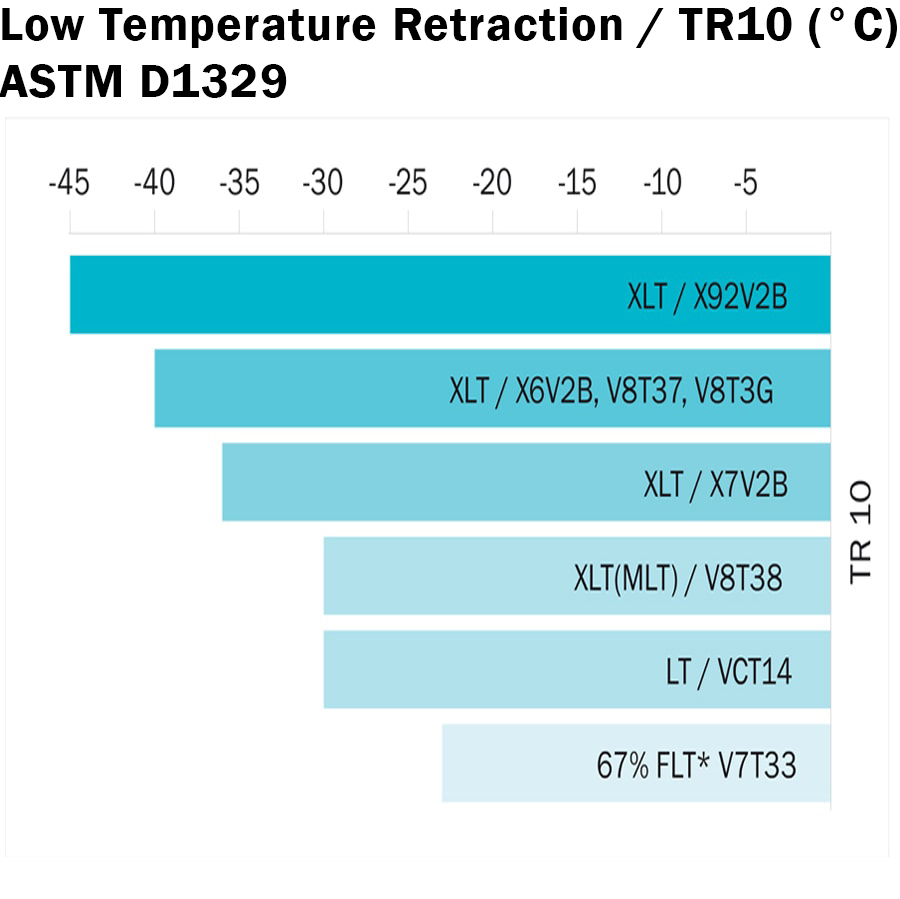

- Retraction (TR10) values ranging from -30 °C to -45 °C / -22 °F to -49 °F

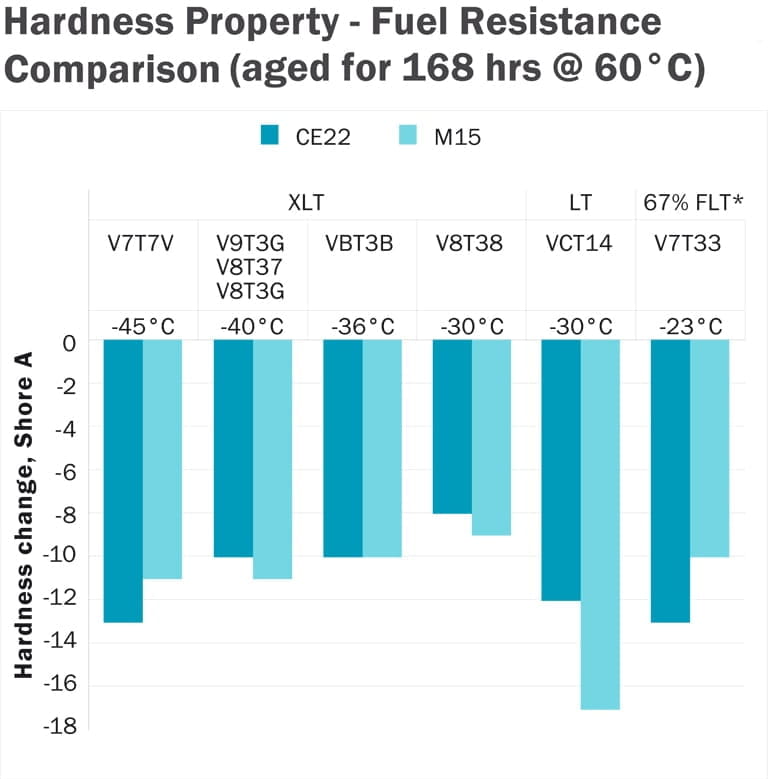

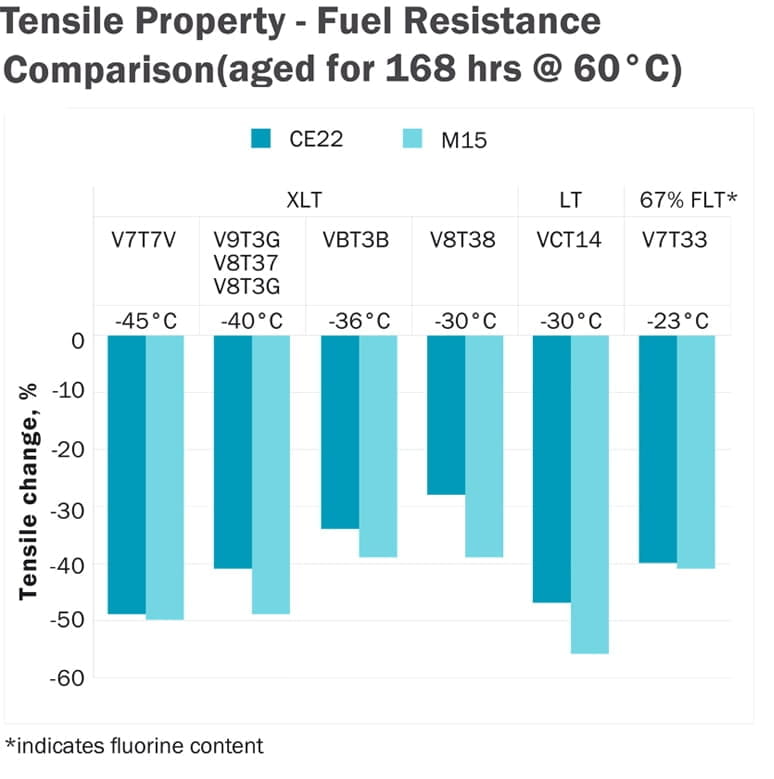

- Increased chemical resistance especially against aggressive ethanol and methanol fuel mixtures

- Increased sealing capability in aggressive environments, for example, in engines

- Excellent retention of mechanical properties

High pressure direct fuel injection

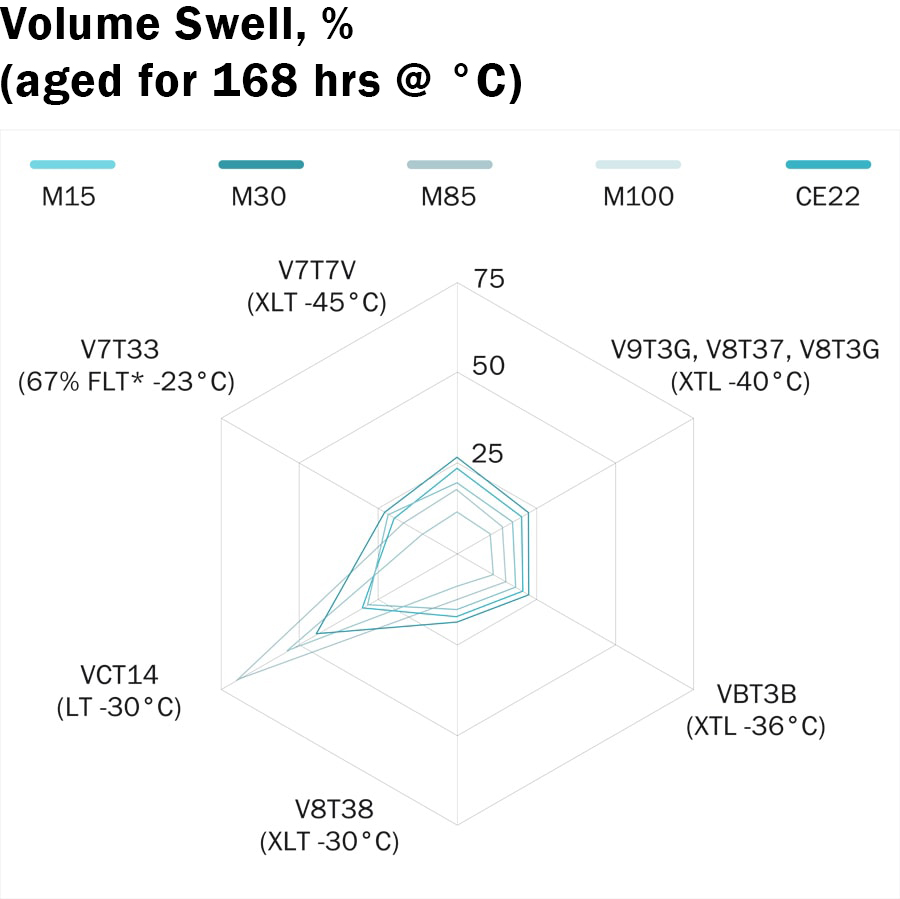

Testing of the new generation XLT materials in bio-fuel applications has proven that this family of materials outperforms and extends the temperature performance capability of traditional fluorocarbon elastomers, with comparably low volume swell and good retention of physical properties. They also demonstrate excellent chemical resistance against most media including more aggressive ethanol/fuel and methanol/fuel mixtures.

Optimized low temperature behavior

With TR10 values reaching - 45 °C /- 49 °F, excellent sealing capability is achieved, outperfoming other fluorocarbon elastomers.