The Isolast® PureFab® range provides the best performance in aggressive front-end processes including deposition, etch, ash/strip, plasma cleaning, and thermal processing such as atomic layer deposition.

The range comprises of leading-edge Perfluoroelastomers (FFKMs) that offer unique properties including high-temperature stability, high purity, exceptionally low trace metal content, and outstanding plasma resistance. This leads to reduced particle generation and ultra-low outgassing performance in high vacuum conditions, enabling end-users to extend their product maintenance cycles while ensuring that process yield is maximized.

To ensure purity of product, all Isolast® PureFab® seals produced and packed in a Class 100 (ISO5) cleanroom environment.

Virtual Showroom

Trelleborg Sealing Solutions offers a unique and focused material portfolio to match process chemistry, system location and tool complexity:

lsolast® PureFab® JPF10:

- Fully organic structure

- High purity

- Excellent fluorine and oxygen radical plasma resistance

- Low particle generation

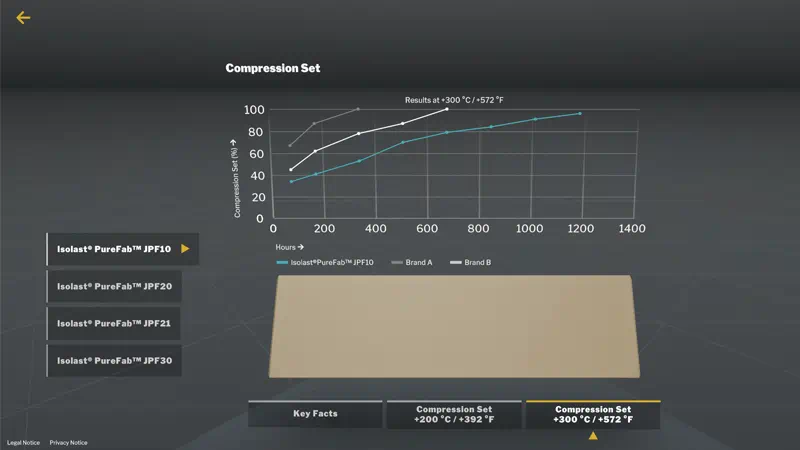

- High-temperature stability over +300 °C

- Excellent chemical resistance, including in steam and amines

- Suitable for processes including dry etching, stripping and remote plasma cleaning

lsolast® PureFab® JPF20:

- Advanced nanoparticle filler system providing minimal particle generation

- Maximum resistance to aggressive ion and radical rich plasma chemistries

- Excellent high-temperature stability to +320 °C

- Suitable for use in all etch processes and critical tool locations where there is a requirement for extreme plasma resistance

Isolast® PureFab® JPF21:

- Proprietary filler system provides excellent oxygen plasma resistance and dimensional stability

- Minimum particulation in NF3 plasma

- Superior sealing force retention over long durations even at temperatures over +300°C extends seal life

- Suitable for etch, deposition and diffusion processes

Isolast® PureFab® JPF30:

- Non-filled, translucent extreme purity material

- Extremely low trace metal content

- Unmatched thermal stability performance compared to competitors’ translucent materials, even at +300 °C

- Suitable for ash and strip processes as well as applications that require low-sealing force

Other materials in the Isolast® PureFab® range:

Isolast® PureFab® J9675:

- Fully organic formulation with excellent resilience

- Ultra-low outgassing performance for advanced node photolithography applications

- Suitable for damping applications where outgassing properties are critical

Isolast® PureFab® J9685:

- Outstanding thermal resistance

- Very low compression set

- Operates in high-temperature thermal processes up to 325°C

- Suitable for thermal processes such as ALD, oxidation/diffusion etc

Isolast® PureFab® J9610:

- Superior chemical resistance for wet process applications

- Very low extractables in aggressive wet process chemicals

- Suitable for CMP, ECD and wet etch applications

Products:

- O-Rings

- Custom-designed seals including rubber-to-metal and rubber-to-plastic bonded products, such as wafer handling products

- FlexiMold™ large-diameter joint free seals

- Centering Rings (NW, KF, ISO)