Current manufacturing techniques at Automated Dynamics were specifically developed over 30 years ago to help companies overcome the limitations of traditional materials and enable new capabilities for critical parts. Within the automotive sector, many of these parts are already being converted to lightweight fiber-reinforced composites, gaining significant performance benefits while also reducing weight. ADC is bringing these advantages of automotive composites to unforeseen heights.

With industry-leading expertise in the automated additive manufacturing of thermoplastic composites, we are working with leading manufacturers to create parts for real-world applications that also allow for scalable processing.

Current manufacturing techniques at Trelleborg Sealing Solutions were specifically developed over 30 years ago to help companies overcome the limitations of traditional materials and enable new capabilities for critical parts. Within the automotive sector, many of these parts are already being converted to lightweight fiber-reinforced composites, gaining significant performance benefits while also reducing weight. We are bringing these advantages of automotive composites to unforeseen heights.

With industry-leading expertise in the automated additive manufacturing of thermoplastic composites, we are working with leading manufacturers to create parts for real-world applications that also allow for scalable processing.

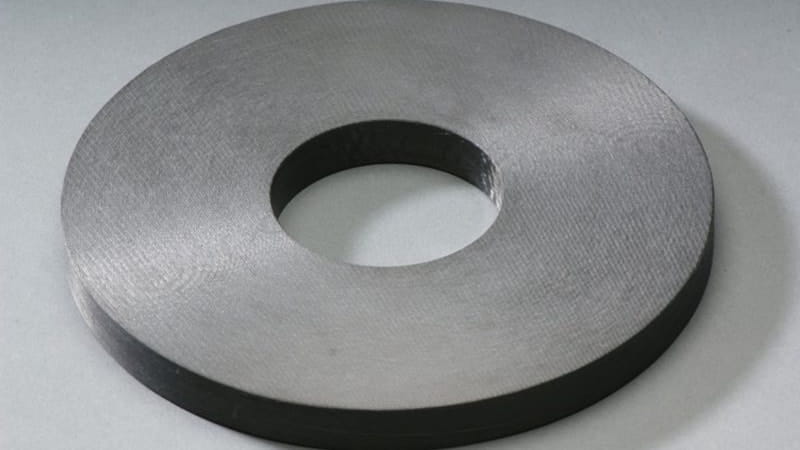

Advanced Composites

Using Automated Fiber Placement (AFP) technology and Trelleborg know-how, we are creating recyclable parts with the lightest weight, greatest fatigue resistance, highest vibration dampening, and best damage tolerance available. By entering the automotive market, we have demonstrated that high-performance parts can be realized even in an industry often requiring high-volume production. In-situ (on-the-fly) manufacturing, high-speed throughput (with our laser heating system), and an additive manufacturing process remove the need for post processing steps. Moreover, we enable residual advantages for the:

- Environment – parts are recyclable and decrease fuel usage

- Consumer – improved mileage and performance

- OEMs – continuous/high throughput manufacturing with new features and material options

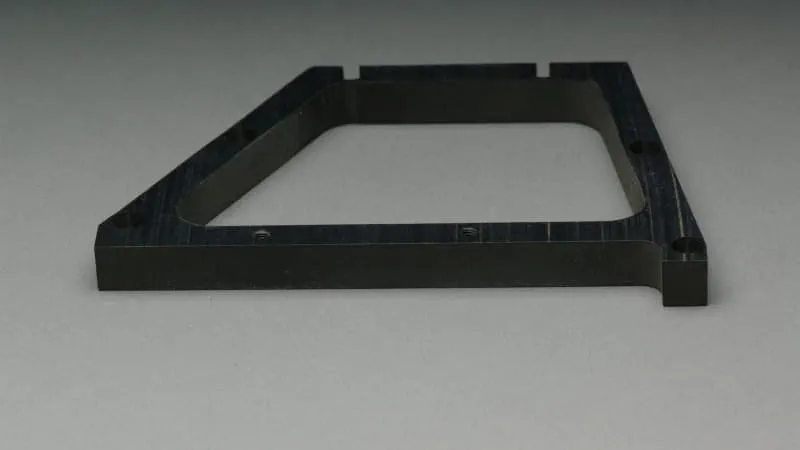

Unparalleled Innovation

Using Automated Fiber Placement (AFP) technology and ADC know-how, we are creating recyclable parts with the lightest weight, greatest fatigue resistance, highest vibration dampening, and best damage tolerance available. By entering the automotive market, ADC has demonstrated that high-performance parts can be realized even in an industry often requiring high-volume production. In-situ (on-the-fly) manufacturing, high-speed throughput (with our laser heating system), and an additive manufacturing process remove the need for post processing steps. Moreover, ADC will enable residual advantages for the:

- Environment – parts are recyclable and decrease fuel usage

- Consumer – improved mileage and performance

- OEMs – continuous/high throughput manufacturing with new features and material options