Materials

Mechanical Properties

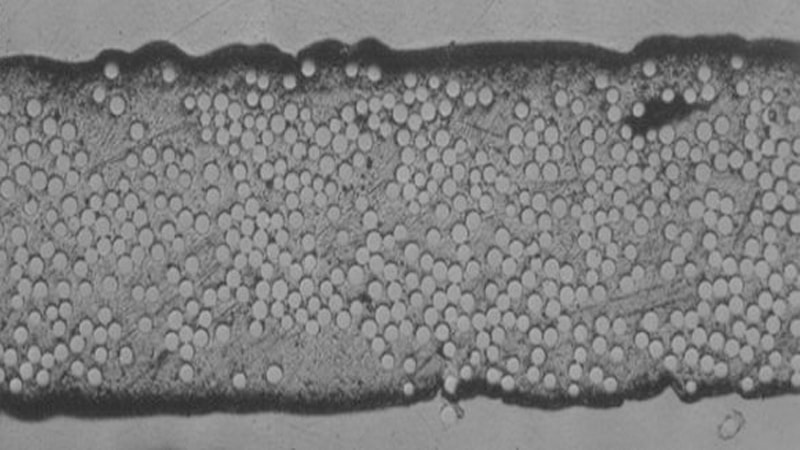

Our standard modulus grade carbon fiber/PEEK composite has 300,000 psi tensile strength with more than 540,000 psi tensile strength available in intermediate modulus and aerospace grade materials. For complete mechanical and material properties, find here the material data sheets

Low Coefficient of Friction

Engineering polymers filled with continuous graphite fibers in our parts offer an exceptionally low coefficient of friction and low wear. They are ideal for applications where high loads and high temperatures are required.

Low Coefficient of Thermal Expansion

Our carbon fiber composite parts can have a very low CTE (Coefficient of Thermal Expansion). We have the ability to design parts to match the CTE of a surrounding metal when required, or we can keep the CTE near zero and the part will grow very little at elevated temperature. This dimensional stability allows our composite parts, such as seals, to be fit with much tighter tolerances than a molded or metal part.

Survives Abrasive Media

Our thermoplastic composite parts survive abrasive media like granite that can grind other composite materials to shreds. Our S2 fiberglass/PEEK structures demonstrate excellent abrasion resistance (sliding and rotating motions) in a wide variety of conditions and is ideally suited for downhole drilling applications.