Trelleborg Presents its Focus on Healthcare & Medical at COMPAMED

Trelleborg Presents its Focus on Healthcare & Medical at COMPAMED

At the COMPAMED 2019 trade fair, Trelleborg Healthcare & Medical exhibits its advanced polymer solutions for healthcare and medical applications. From November 18 to 21, 2019, in Hall 8A at Stand F02, Trelleborg will demonstrate how it helps pharmaceutical and medical device companies improve patient quality of life by forming lasting partnerships with customers to develop innovative, reliable engineered polymer solutions for demanding medical, biotech and pharmaceutical applications.

Pooling competencies, continuing to grow

For over 20 years, Trelleborg has been developing and supplying silicone tubing, film and custom molded components, as well as elastomer and polymer seals, to manufacturers for their biotech and pharmaceutical equipment, and medical devices. Trelleborg Healthcare & Medical brings together all its global sales, development, design and manufacturing facilities to better meet its customers’ needs.

Linda Muroski Global President, Trelleborg Healthcare & Medical, says: "We are focusing our global expertise in healthcare and medical to provide our customers the industry-specific solutions they require. Creating a dedicated healthcare & medical operation strengthens our ability to respond even faster to customers’ requests, whether they be around new innovations, expanded capabilities or potential geographical expansion.”

Andreas Schmiedel, Technical Manager at Trelleborg Healthcare & Medical, adds: “For example, as specialists in healthcare and medical, we closely monitor changes in the regulatory environment, such as the new EU Regulation on Medical Devices 2017/745 (MDR) and revised ISO 10993. We are capable of proactively developing and recommending solutions to support our customers in meeting stringent requirements. One of our goals, through partnership, is to bring our customers’ solutions to market faster.”

Silicone tubing for long-term implants

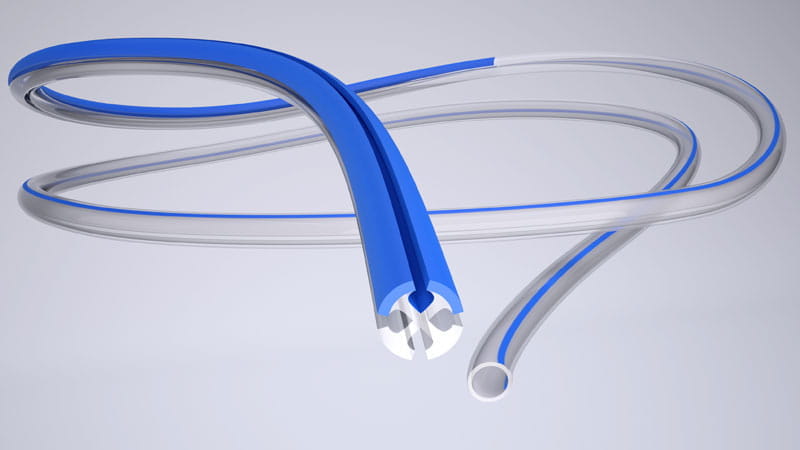

At COMPAMED Trelleborg will showcase its medical silicone tubes for long-term implants. Due to their biocompatibility and physical resistance, they play an important role in medical applications, both as conduits to transport liquid or as insulators for cables and sensors. The products must meet high precision, control and process stability demands, and also be implantable for up to several years. All long-term implantable silicone products are processed in cleanroom environments.

Trelleborg has developed a range of specialty tubing and hose. Tubes are available in a full range of sizes and are designed jointly with customers to meet their individual application needs. Examples include multi-lumen, flexible, kink-resistant and silicone tubing with a plastic core for minimally invasive instruments, catheters and probes.

Trelleborg’s patented GeoTransTM technology enables a significantly greater variation in the geometry of tubing, supporting unique, customer specific designs. For example, one lumen can be separated into two lumen (or two into one) during the extrusion process, eliminating the need for a molded component between the different segments. Additionally, lumen can be stopped and restarted or the dimensions of the tubing can be changed, which is often necessary for wound drains. Reducing the process steps in manufacturing saves time and decreases potential sources of failure, thereby reducing costs and mitigating risk.

Custom parts from initial design to serial production

Trelleborg Healthcare & Medical partners with customers from the initial design phase and prototyping through to supplying the product and bringing medical devices to market. Engineering and material expertise, together with a full portfolio of manufacturing capabilities, meets customer needs at every stage and accelerates time to market for new medical devices. Trelleborg facilities conform to ISO 13485-2016 to ensure medical devices and services meet customer and regulatory requirements.

Trelleborg Healthcare & Medical manufacturing facilities specialize in producing custom silicone and thermoplastic components, including micro-molded parts, parts with complex geometries and multi-component parts. In-house toolrooms develop high precision Liquid Silicone Rubber (LSR) tooling combined with advanced automation technologies to support production volumes ranging from prototype to high-volume serial production.

A range of value-added services, including slitting, drilling, cutting, bonding with medical grade adhesives and final assembly is available. These services are performed in a highly automated state-of-the-art production environment and all of it will be on display at COMPAMED.

Silicone film for burn and wound treatment

Also on show at COMPAMED, are Trelleborg’s silicone sheeting and film capabilities. For example, Trelleborg has, in partnership with a customer, developed drug-eluting silicone film, which can be used to treat chronic wounds and burns. There is increasing demand for flexible, breathable wound dressings that minimize scarring, reduce the risk of infection and accelerate healing.

"Depending on the medical application, wafer-thin silicone gel films containing active pharmaceutical ingredients are being increasingly used in place of more traditional burn and wound care treatments," continues Schmiedel. "The silicone film can be combined with antibiotics or decongestants, which can potentially replace epidermally applied medication. These drug-eluting silicone films significantly improve treatment for the patients."

COMPAMED 2019 in Dusseldorf, Germany, from 18 to 21 November, is a melting pot for high tech solutions, where product developers and suppliers from the entire medical sector meet. Trelleborg will be present at the show in Hall 8A at Stand F02.