All Trelleborg sites

Close- Group Trelleborg is a world leader in engineered polymer solutions that seal, damp and protect critical applications in demanding environments. /seals/-/media/group/site-switch/trelleborg-group.jpg?h=264&w=293&rev=b3492bd026aa498f90103f0288dfc4e6&hash=72864F3ACBDA1724A3E5250CD2424C68

- Antivibration Solutions Helping to remove unwanted vibration and noise in Rail, Marine, Off-highway and Industrial applications /seals/-/media/group/site-switch/antivibration.jpg?h=264&w=293&rev=cac94d89d97a4764937febb8422dbc03&hash=12A523DC26C13E43E5FE7089DB9F3486

- Boots Advanced dynamic protection for Automotive Driveshaft and Steering Gears /seals/-/media/group/site-switch/testing-boot-cold-1.jpg?h=264&w=293&rev=e398df5cfb7d4080a18fb803255e50bc&hash=7CAF09916CBE838BAFA919AED27F6B08

- Damping Solutions Automotive noise damping shims & insulators /seals/-/media/group/site-switch/damping-solutions.jpg?h=264&w=293&rev=e4886fdb3c364d319c626e35fe923d04&hash=D4E08121DF08463FFBFCA5AD275A4AEF

- Engineered Coated Fabrics Trelleborg’s Engineered Coated Fabrics business unit, a world-leading producer of specialty polymer-coated and calendared materials, operates under the Coated Systems business area. /seals/-/media/group/site-switch/engineered-coated-fabrics.jpg?h=264&w=293&rev=2fdac9be0f434313920fb532c7262a43&hash=23E184F52CD740B530FC08738E530DAC

- Fluid Handling Solutions Industrial Hose, Expansion Joint, Oil & Marine Hose, Rubber Sheeting and Mining Applications /seals/-/media/group/site-switch/fhs.jpg?h=264&w=293&rev=6cf337a4c82642b59e004d0a9199ea15&hash=4D0CA37036809222E4A78E27A8A64AAB

- Medical Solutions Supporting the Healthcare and Medical industry with advanced polymer engineered components /seals/-/media/group/site-switch/healthcare-and-medical.jpg?h=264&w=293&rev=627ac8af44794afb8aa913220f959254&hash=CCFF239DAA8847077E4206C7843BEFE9

- Marine & Infrastructure Highly engineered polymer solutions for marine and civil infrastructure /seals/-/media/group/site-switch/marine-and-infrastructure.jpg?h=264&w=293&rev=b209d371ac264b6f85b7b8167ef0860c&hash=51AA9CFA98963463E6162A8DE91DFDA2

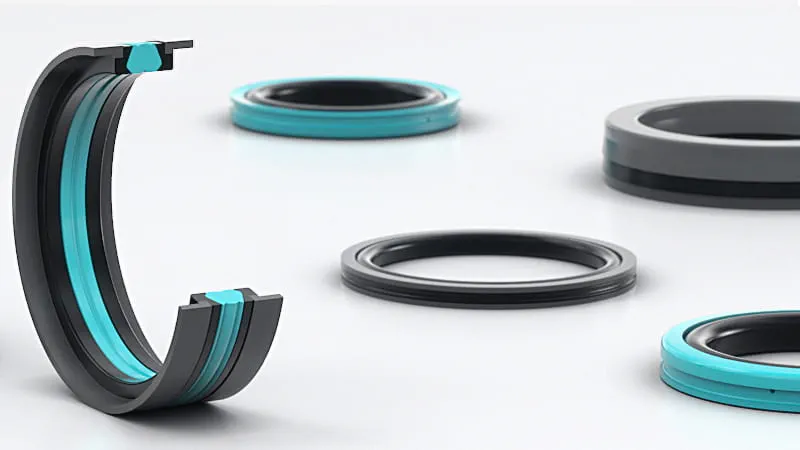

- Sealing Solutions Sealing and bearing solutions for Industrial, Automotive and Aerospace applications /seals/-/media/group/site-switch/sealing-solutions.jpg?h=264&w=293&rev=158324dc66494c6a8450812cbd4a794b&hash=6E81A625A8BFC9F2759D88F9EE878AA1

- Seals & Profiles Seals for applications in buildings and construction, aerospace, automotive, agriculture, renewable energy and water infrastructure. /seals/-/media/group/site-switch/seals-and-profiles.jpg?h=264&w=293&rev=c630d927a2a9455e851bb1a4fd6da61e&hash=12B561EA8906F4AA6257EA73716A443C

Bulgarian

- Bulgarian | български

- Chinese (Simplified) | 中文(简体)

- Chinese (Traditional) | 中文(繁體)

- Czech | čeština

- Danish | dansk

- English

- Finnish | suomi

- French | français

- German | Deutsch

- Hungarian | magyar

- Italian | italiano

- Japanese | 日本語

- Korean | 한국어

- Polish | polski

- Portuguese | português

- Spanish | español

- Swedish | svenska

- Turkish | Türkçe

- Vietnamese | Tiếng Việt

Counter Surfaces

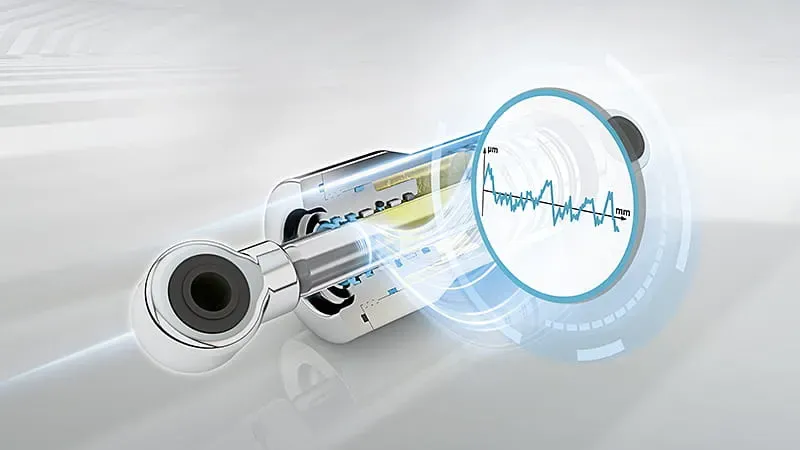

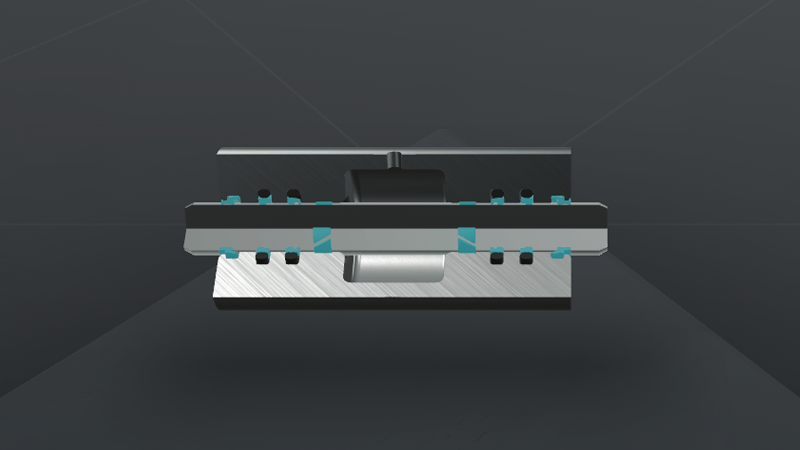

Optimize dynamic chrome plated applications now

To maximize the performance in hydraulic systems, the interaction of seals, hydraulic fluid and the finish of the mating surfaces must be optimized.