Automated Inspection / Quality

- Fully automated visual inspection including dimensions and surface properties

- High flexibility with reliable quality and 100% quantity control

- Facilities are certified to ISO 9001:2008 and ISO/TS 16949:2009

- Identifies and controls irregular profiles with reference to the basic profile

- Inspects up to 5 parts per second

- Six camera and 360° sensor inspection capabilities provide inner and outer diameter analysis of each seal

EDI

Trelleborg Sealing Solutions has invested heavily in EDI (electronic data interchange) infrastructure to match its customers’ demands for data transfer. Customers’ order and delivery schedules are directly transmitted to our ERP System. A manual input is no longer necessary, saving time and making order scheduling more accurate.EDI increases the efficiency of order processing by reducing misunderstandings as well as costs.

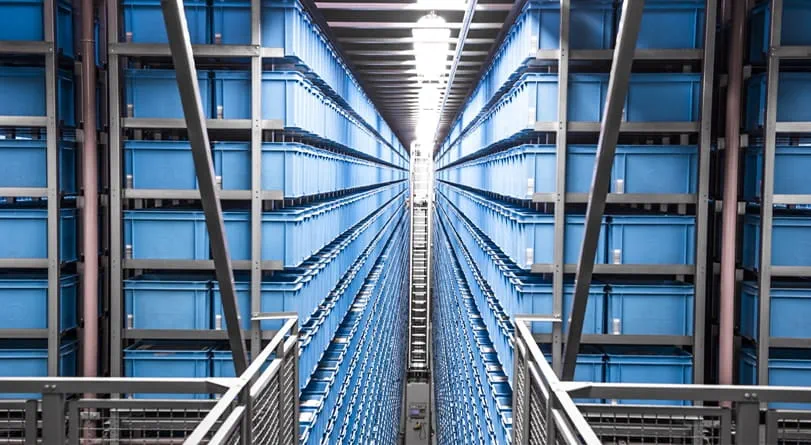

Logistic Center Services

Trelleborg Sealing Solutions is able to meet your complete logistic needs through its advanced global and local network of manufacturing sites, sales and logistics centers. We are always close by with headquartes in Europe, Americas, Japan and china.

In addition, we also offer advanced customer optimized services such as inspection and certification, surface treatment, special marking, blister packaging, KLTs , single bag & tag, and kitting or cutting. Standard packaging as well as customer specific packaging with customized logos or part numbers are also provided upon request.

Dock to Stock

- Incoming parts bypass customer’s quality inspection, saving time and costs

- Parts are certified, approved and inspected by Trelleborg personnel, allowing products to be shipped directly into customer stock and preventing loss in qualitystandards.

Research & Development For Automotive Products

In R&D we are using automotive specific test stands and verification programs.

Our test portfolio includes for example temperature test cycles for material testing and application test cycles for specific applications like rod seals, piston seals, scrapers, Rubore® seals and Turcon® Roto L.

We are using original parts, as well as original designs (for example housings) which are very similar to the real parts and design prototypes for testing rod seals, piston seals, static seals, Rubore® Frame and Flat seals . So we can see how the seal performs at realistic conditions.

If necessary, we do a stress analysis to prove the behavior of the sealing; during this process we do not only consider the sealing itself but also the whole system - including for example used oil, reverse surface, scraper, energizer and the steering.

We can rely on high tech analysis tools for example special microscopes, infrared devices for IRHD measurement, temperature-controlled ovens for high temperature and lifecycle tests, devices for analyzing the composition of the seal and for performing the TR10 test for O-rings.

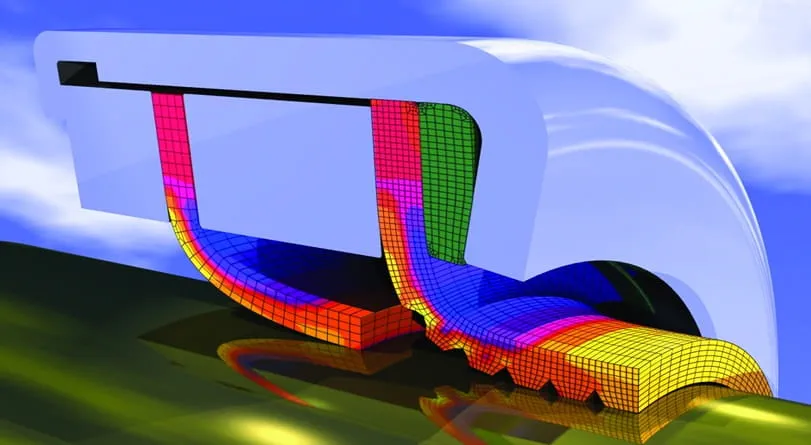

FEA (Finite Elemente Analysis) and Simulation Software

Trelleborg Sealing Solutions has an unique knowledge and long experience how to simulate sealing systems made of non-linear material.

We have our own test specifications, developed especially for FEA purpose and are able to make use of our extensivematerial database. Our internal development of advanced simulation methods optimizes currently the simulation for our product portfolio and its range of applications.

FEA is a simulation method which involves assumptions – never take it as absolute reality. Good engineering work is still needed to get the best sealing solution. Our FEA knowledge is treated as TSS intellectual property.

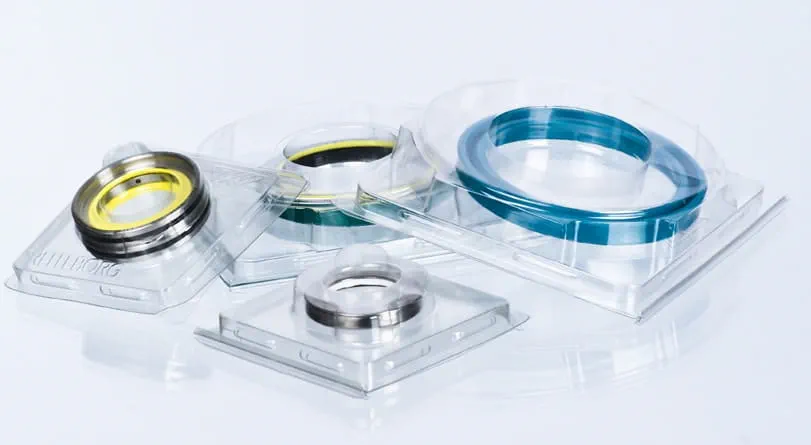

Special Packaging System For Seals

Tube / Mandrel Packaging

- Transparent plastic tubes or paper mandrels

- Different colors and sizes available

- Any kind of seals particularly for critical geometries

- The tube can be mounted directly into the feeding station in the production line at the customer's production site

- Resistant to environmental conditions and mechanical damage (e.g., transportation, water, dust, etc.)

- Improve packaging costs with reusable packaging

Blister Packaging

- Different variations of shapes and sizes

- Transparent or black PET materials available

- Various thickness from 3 to 6 microns

- Provides seals with special protection

- Offers cost effective packaging solutions and is recyclable

- Resistant to environmental conditions and mechanical damage (e.g., transportation, water, dust, etc.)

- Easy to store, stack and use in automated environments

KLT - Small load carrier

We pack the seals to customer specification in VDA compliant small load carrier (KLT) which is used by default from automotive industry to optimize the logistic chain. The small load carrier (KLT) is provided by the customer in customer-specific color and size. The VDA small load carrier (KLT) is a standardized plastic packaging system. Detailed information about this system you can find in the recommendations 4500 and 4504 of the VDA (association of the automotive industry). The small load carrier (KLT) is modular adapted to the euro pallets (1200 cm x 800 cm) as well as to the ISO pallets (1200 cm x 1000 cm) and can be used universally. The dimensions of the containers are printed directly on the container for easy calculation. VDA labels can be attached to customer specification on the prefabricated side pockets. This packaging system greatly facilitates the deployment of the parts needed for assembly. A manually and mechanically removal is easy possible for example also by a cross robot.

Surface Treatment and Markings

Trelleborg Sealing Solutions has three technical cleanliness standards based on accepted international standards:

- Defined particulate cleanliness As components and assemblies become smaller, more complex and have higher efficiency, functional density is increased. This narrows tolerances and makes component parts more sensitive to particle contamination.

- Freedom from paint wetting impairment substances Clean components are a particular requirement within the lacquering process. The surface to be lacquered, as well as the smallest components within the painting system, have to be free from any contamination that may cause disturbances or disorders in the lacquered settings.

- Class 5 cleanroom quality, ISO 14644 – 1 Some automotive components, such as electronic parts, require the ultimate in clean production, with the slightest contamination, even from airborne particles, potentially affecting component function. This is eliminated using cleanroom production where the concentration of airborne particles is controlled.

Flexcoat™ : Friction-free running

Trelleborg Sealing Solutions has developed a number of micro-thin performance coatings and surface modifications that improve the friction performance of elastomer seals. Choosing one of these has the following benefits:

- Saves time and enhances safety and security in automated assembly

- Cleaner process reduces associated time and cost of maintenance

- Ensures shorter process-flow times

- Increases opportunities for the use of simple and cost-effective elastomer seals

- Extends service life through improved wear properties

- UV coating indicators for automated detection

- Color coated for easy identification

Special Marking

- Inkjet marking on part from colored dots to customer part numbers or customer references on any kind of seal

- Ease of automated robotic recognition for safety critical applications

- Special identifier of specific parts on customer site for sourcing and quality tracking