R&D Capabilities

Working together to develop custom sealing solutions

When standard solutions don’t meet your needs, our engineers work with you to develop a customized component that does. Our Research and Development centers are proud to offer the following:

- Close collaboration with our customers

- Customized solutions using the latest in non-linear Finite Element Analysis (FEA) techniques

- Cutting edge manufacturing techniques to optimize performance

- Material development to meet requirements and standards

Material Development and TestingThe development of polymer materials blends the science of understanding material chemistry with the art of balancing a wide range of performance characteristics to produce the optimal materials for each unique customer need. The potable water and sanitary segments are no exception, and our material development is tailored to emerging trends within the industry:

- Material development experts are located in all of our manufacturing facilities and R&D centers around the globe.

- R&D centers are equipped with material testing and analytical laboratories to guarantee materials are capable of performing in a wide range of environments and achieve relevant industry material certification.

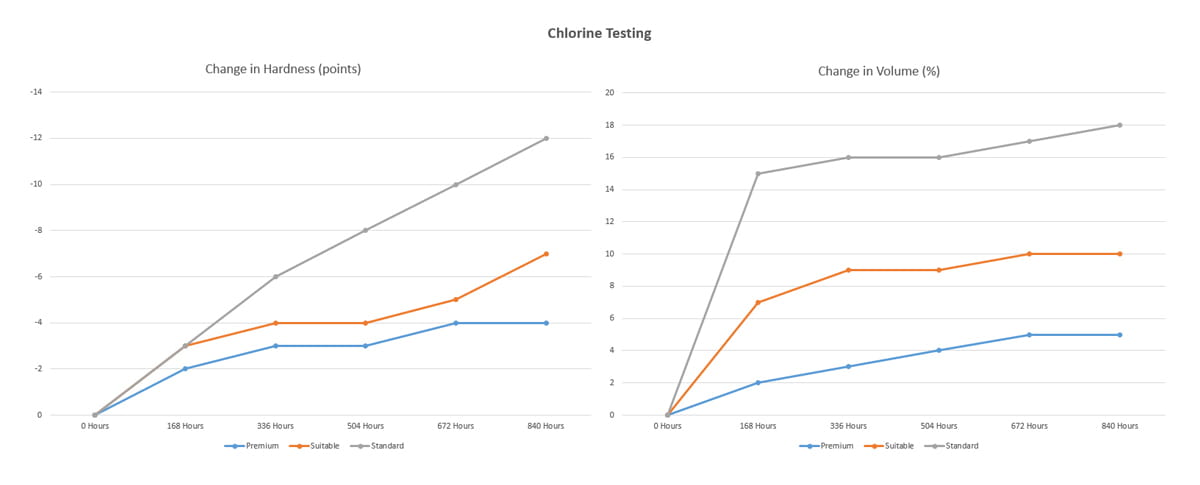

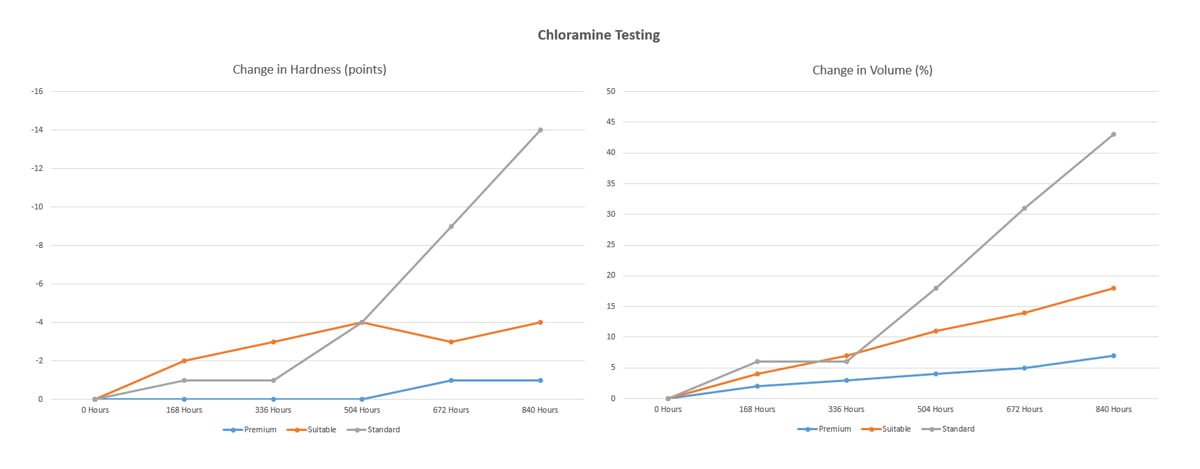

Application critical testing is offered for the potable water and sanitary industry, such as chloramine and chlorine resistance testing.

Trelleborg has developed its own testing regime, similar in nature to current ASTM tests, comprising an 840 hour immersion test at 70° C / 158 °F, followed by visual inspection and determination of changes in hardness and volume. Combined with new Computational Fluid Dynamics (CFD) capabilities, seals and materials can be validated and performance measured before field use, leading to reduced costs and higher reliability.

Material Development: Chlorine and Chloramine

Chloramine Testing - Changes in Hardness and Volume