FlatSeal™ HMF60 Series is manufactured using advanced techniques to fully bond the phlogopite mica to the expanded stainless steel metal (grade 1.4404/316L) layer. This produces a robust gasket, from which even complex gasket geometries can be formed using all common methods, including punching and cutting.

Features and benefits

- Insensitive against oxidation

- Incombustible (DNI = does not ignite – according to ASTM SAE J369 fire test)

- High chemical resistance

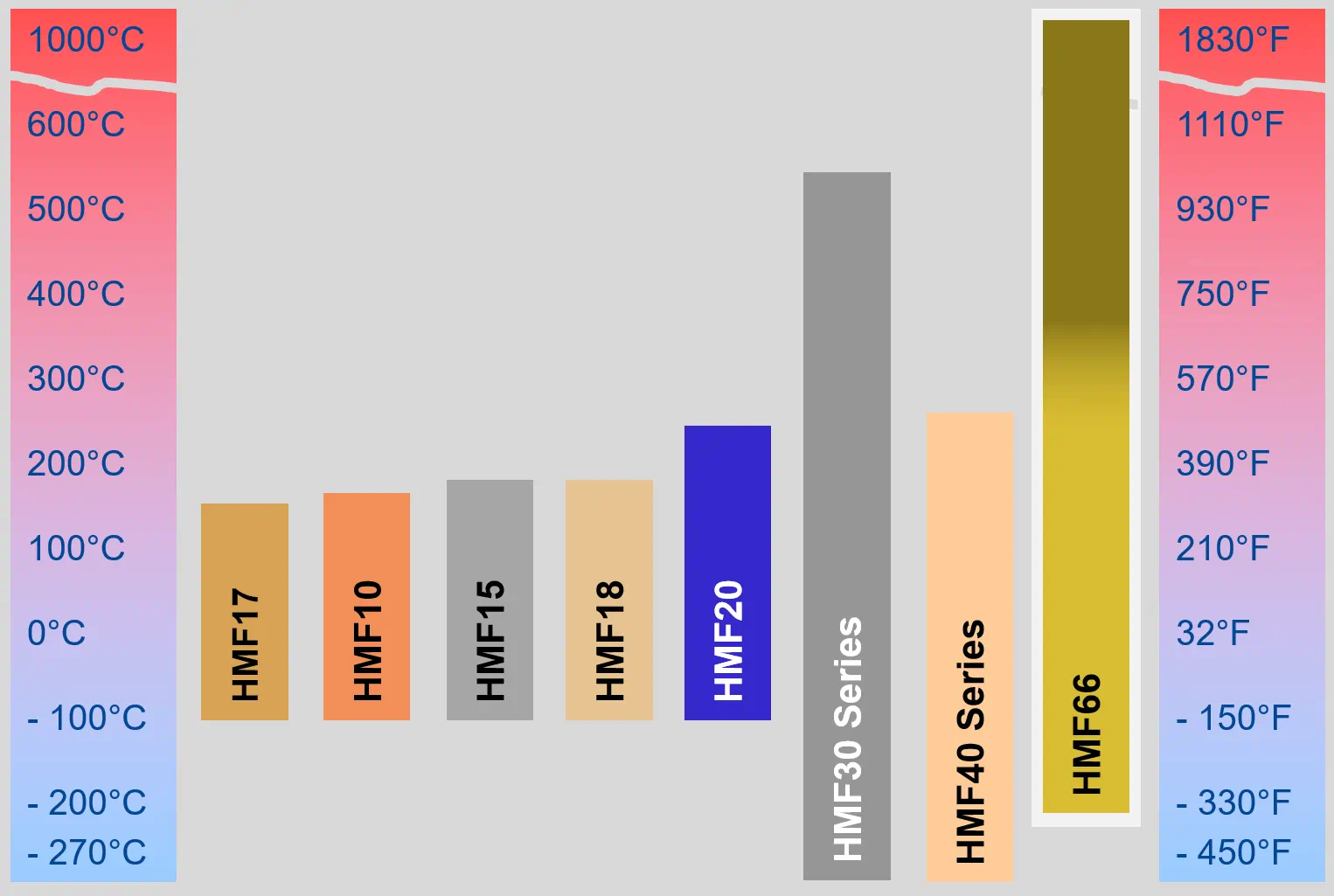

FlatSeal™ HMF66 – engineered for the highest temperatures

Specially engineered for use in the most demanding operating environments, FlatSeal™ HMF66 consists of a phlogopite mica composite with an expanded metal inlay, combining superior sealing performance with enhanced strength. The unique layered material demonstrates:

- Outstanding temperature performance for environments to 1000 °C / 1832 °F

- Wide ranging media compatibility, including aggressive and corrosive chemicals

- Extended service life

- Excellent gasket stability for optimized handling and assembly

- Electrical insulation properties, preventing the flow of electric current

FlatSeal™ HMF66 is manufactured using advanced techniques to fully bond the phlogopite mica to the expanded stainless steel metal (grade 1.4404/316L) layer. This produces a robust gasket, from which even complex gasket geometries can be formed using all common methods, including punching and cutting.