Overview

The most effective method of riser pipe corrosion protection.

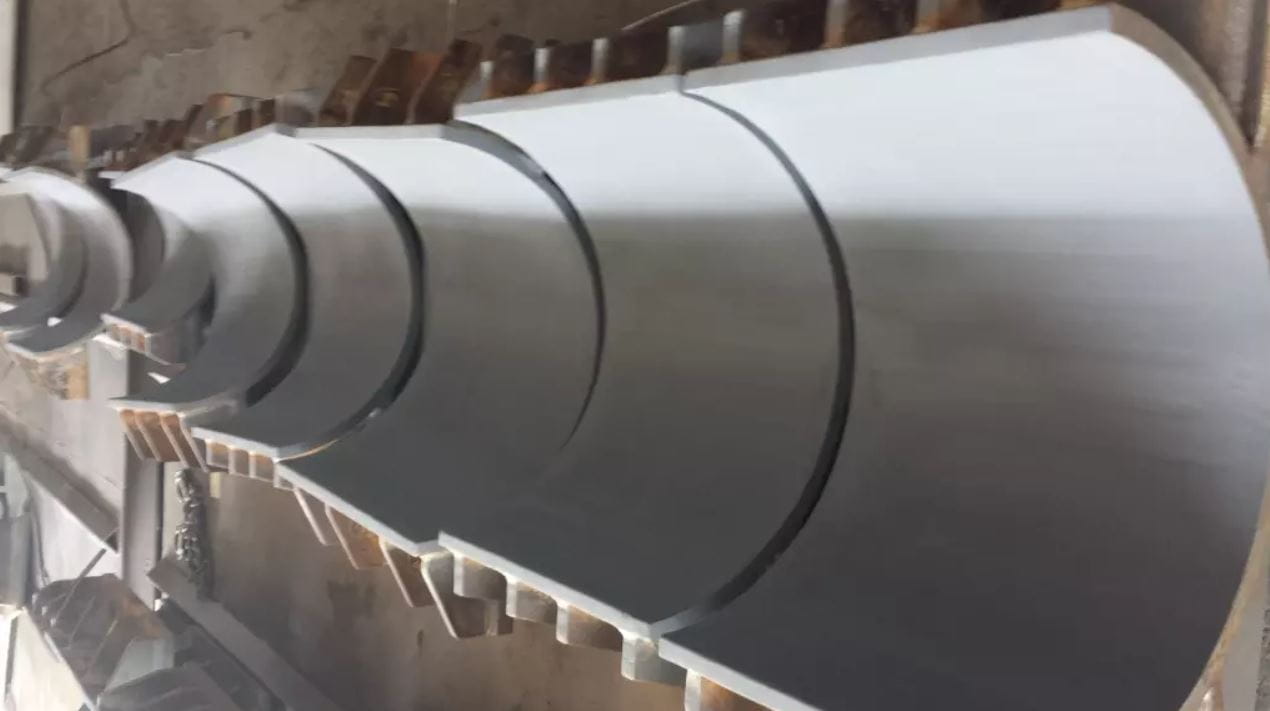

Elastomer coating on risers as a form of corrosion protection is an extremely popular solution with owners of oil & gas platforms. It is widely recognized in the offshore industry as the most effective method of riser corrosion protection particularly in the highly corrosive splashzone region.

Two common types of elastomer coating are available Polychloroprene (Neoprene) and EPDM (Ethylene Propylene Diene Monomer). Trelleborg can incorporate a range of protective qualities into an elastomer coating to suit your protection needs.

For example, anti-fouling coating can be added on to the elastomer to inhibit marine growth. This is achieved by using a Cu/Ni 90/10 sheet chemically bonded to the elastomer or a chloroprene sheet sprayed with Cu/Ni 90/10 granules and subsequently chemically bonded to the riser rubber coating.

Our services include field coating anywhere in the world. We are able to perform in-situ vulcanization with our specialized equipment and high performance elastomers. Our personnel are qualified to work offshore and have all the necessary safety and sea survival certification/ training.

With an extensive track record spanning over 20 years in the offshore industry, our reputation makes us a preferred coating supplier and we can offer elastomer coating anywhere in the world.