Overview

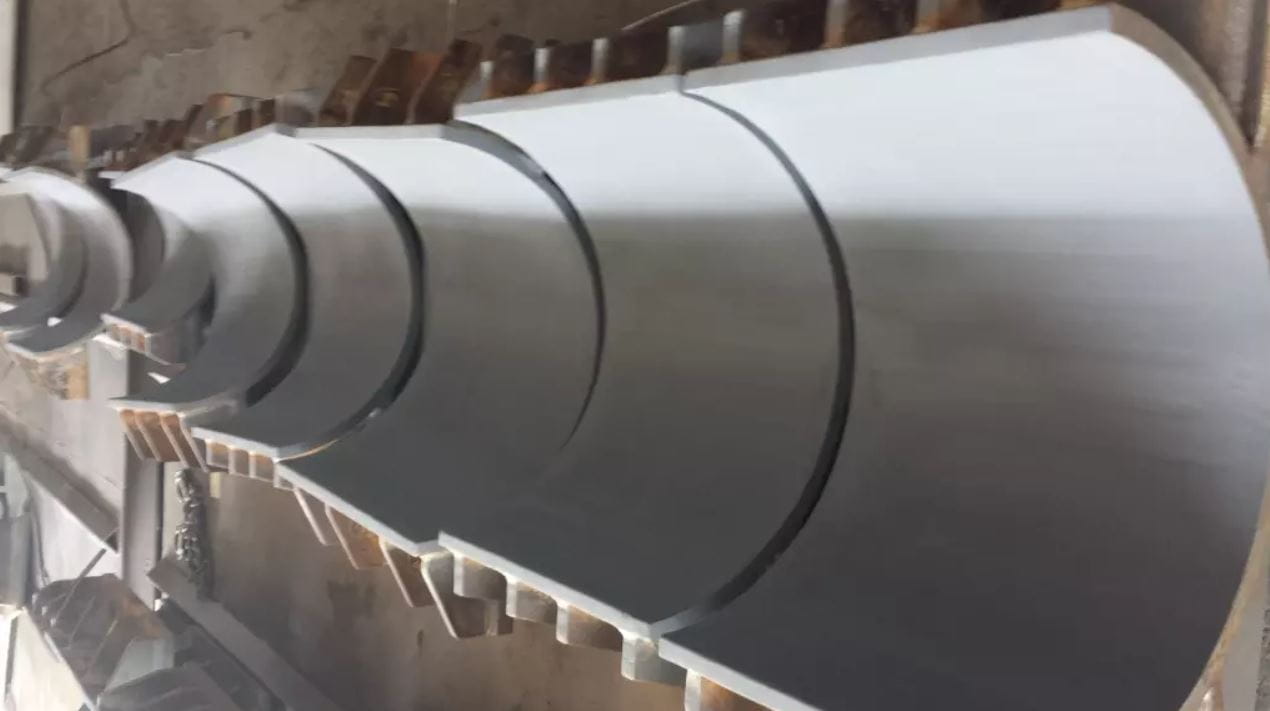

Riser clamps are frequently internally coated with an elastomeric polymer, to prevent damage to the riser clamp and the riser pipes during installation and operation. As the riser pipes may move about due to sea swell or weather conditions, the impact of this motion will be absorbed and mitigated by the riser clamp coating.

The most common type of elastomer used in this instance is polychloroprene (neoprene); its ability to withstand hydrocarbon and the harsh marine environment found in the splashzone is especially useful. This elastomer coating can either be in the form of plain/flat or ribbed profile. It is bonded either through a cold-bonding (glue) method or hot-bonding (vulcanization) method.

While we offer field-coating services with a highly trained, professional team, another option is to send us your clamps for coating before their final offshore installation due to our strategically located manufacturing facilities.