On-site Tests

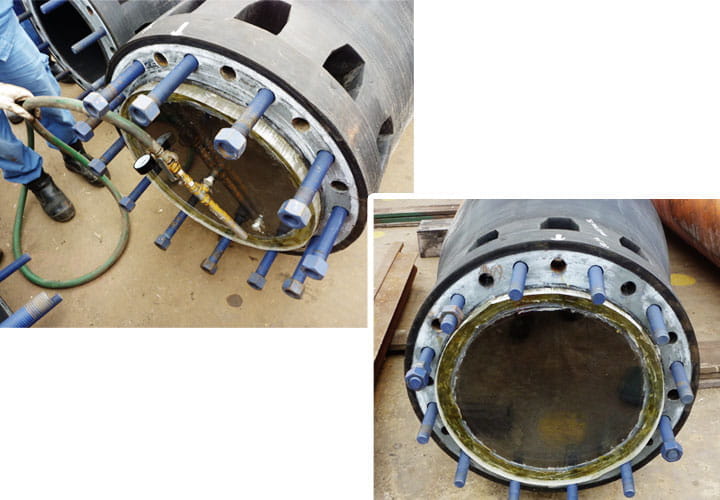

Vacuum Test

The purpose of the test is to verify the integrity of the inner liner.

- Clean the gasket with water.

- Place a translucent background of sufficient thickness at each end.

- Evacuate the value of 0.85 bar for 10 minutes.

- Monitor using a light source inside the hose and identify any changes in behaviour and defects.

- Record and compare the state of the inner liner with observations made during visual inspection.

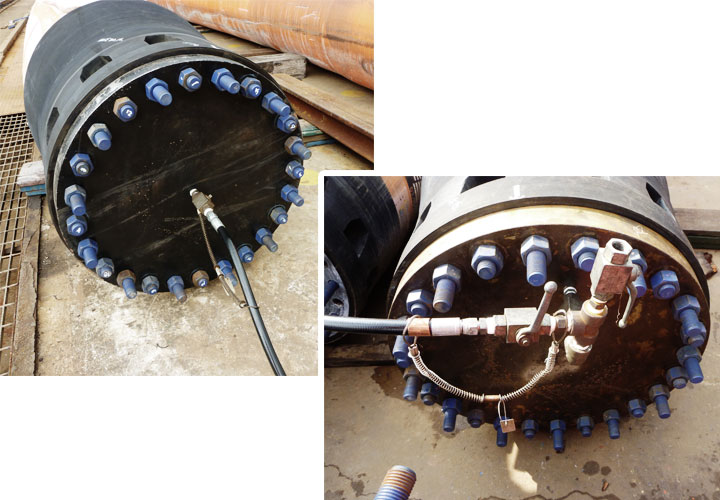

On-site Hydrostatic Test

- Check the tightness of the hose at a pressure generally higher than in operation.

- Verify the behaviour of the hose structure: elongation ; deformation dilation.

Note: The hose is in position right on planks, metal pipes ....., so as to elevate the flanges of the floor and release the flexible constraints. - Fill with water and drain thoroughly hose lifting the drain side end (air pocket).

- Mounting pressure to 0.7 bar and hold 5 min. Taking the length measure of the hose (L0).

- Increase the pressure from 0.7 bar to half of the working rated pressure. Take 30 minutes and reduce pressure 0.7bars.

- Increase the pressure from 0.7 bar to the working rated pressure. Hold 5 min and measure the length of the hose (L1).

- Decrease the pressure to 0 bar and take 15 minutes.

- Increase the pressure to 0.7 bar, and measure the length of the hose (L2).

L1 - L0 / L0 = temporary extension

L2 - L0 / L0 = permanent elongation

These values will be identified and compared with those measured in factories. For a temporary or permanent elongation greater than 2%, the hose should be removed from service.