Applications

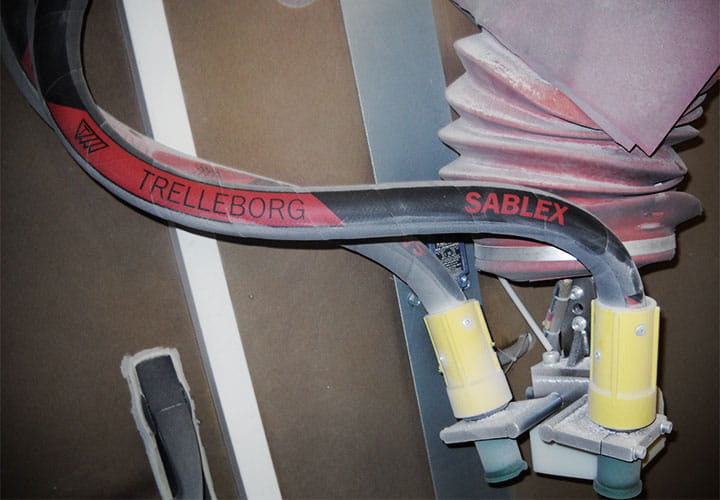

Pneumatic discharge of powder (lime, cement, fertilizers, etc.), grain, sand, silica, minerals, or sized products (fertilizers, PVC granulates, cereals, etc.).

Sand and shot blasting of buildings and metal parts.

Advantages

Highly resistant to abrasion due to friction and atmospheric conditions.

Electrical conductivity is assured by the tube compound together with a metal braid.

Excellent resistance to bending and twisting.

Design

Technical drawing

Overview

Inner tube

wear resistant NR, smooth, black,

Reinforcement

synthetic textile,

Cover

weather resistant NR, fabric impression, grey,

Temperature range

-30 to +70

Electrical properties

conductive tube and built-in conductive wire.

Technical Specifications

| ID (mm) | Wall thickness (mm) | OD (mm) | Working Pressure (bar) | Bursting pressure (bar) | Max. vacuum (bar) | Bending radius (mm) | Weight (kg/m) | Length (m) | Article number | Stock or min. order (m) |

¤ Upon availability. * Tolerance on length: ± 1 % (ISO 1307 Standard)