Tape Laying

Automated Tape Laying (ATL) utilizes a single, wide, unidirectionally reinforced, slit tape to layup simple, gentle contours or flat parts. This is typically the case within Trelleborg Sealing Solutions as well, but we have taken some liberties with the definition when it improves the Customer’s automation solution. The need for individual tows or a single wide band should always be a compromise between the part’s surface geometry and the manufacturing throughput.

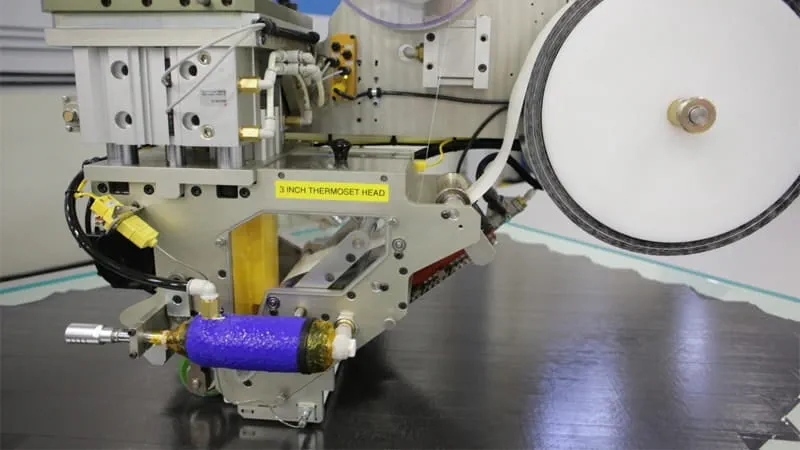

Simple geometries over large surface areas are typically approached by the industry with wide 6.000 inch — 12.000 inch (152.40 mm — 304.80 mm) tapes. While this solution may adequately handle the overall simple geometry, localized pad-ups and occlusions may still demand hand laid up or prekitted plies and hand trimming on the part surface. Complex ATL systems with “flying knife” technology may trim to a perfect edge of ply (EOP), but the scrap generated must be deposited off the part or removed by hand. This precise EOP capability seems attractive, but it adds to machine complexity. This increases cost and manufacturing time. It may be wise to consider a tailored approach using multiple wide tapes, perhaps 1.000 inch (25.40 mm), to approximate the EOP while maintaining higher throughput and reducing scrap.