Hydrogen plays a critical role in the transition to sustainable energy, both as a fuel source and as a storage medium for surplus energy from renewable sources. Due to its inherent characteristics, it is difficult to seal but the expanding H2ProTM range offers validated, reliable solutions for a wide array of applications including pumps, valves, connectors, and numerous other devices in the hydrogen supply chain.

Supporting the energy, power generation, off-highway, truck and bus, chemical processing and transportation, aerospace and marine industries, all H2ProTM materials are validated to our proprietary standards in a range of challenging real-world conditions typical of hydrogen environments.

We offer proven products wherever seals are required in hydrogen applications. The H2ProTM range encompasses solutions for compressed hydrogen gas and liquid hydrogen, and in the automotive market seals for hydrogen internal combustion engines and fuel cell vehicles.

- Specifically engineered for hydrogen and fully tested to meet relevant standards and directives

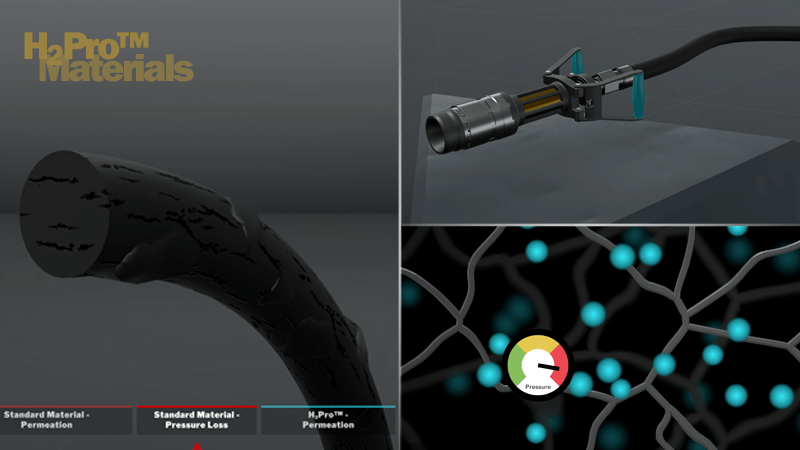

- Proven to withstand challenging application environments including resistance to leakage and permeation, high pressures and extreme temperatures, and rapid gas decompression

- Excellent application-specific wear and extrusion properties, extending service life while reducing maintenance, replacement and total cost of ownership

- Backed by the service of Trelleborg’s sector-leading engineers able to offer custom solutions

H<sub>2</sub>Pro™ Materials

The H2Pro™ range of validated materials offers solutions for the entire hydrogen value chain – production, transport and storage, and end use, and includes:

- A range of ethylene propylene diene monomer (EPDM) materials for a broad range of application conditions

- Fluorocarbon (FKM) which excels in high-temperature environments

- Silicone compounds offering a wide service temperature range

- Polyurethane (PU) grades ideal for extreme wear and durability applications

- Thermoplastic compounds for excellent performance in cryogenic and liquid hydrogen sealing

- Metal grade for ultimate static sealing

Validating Materials

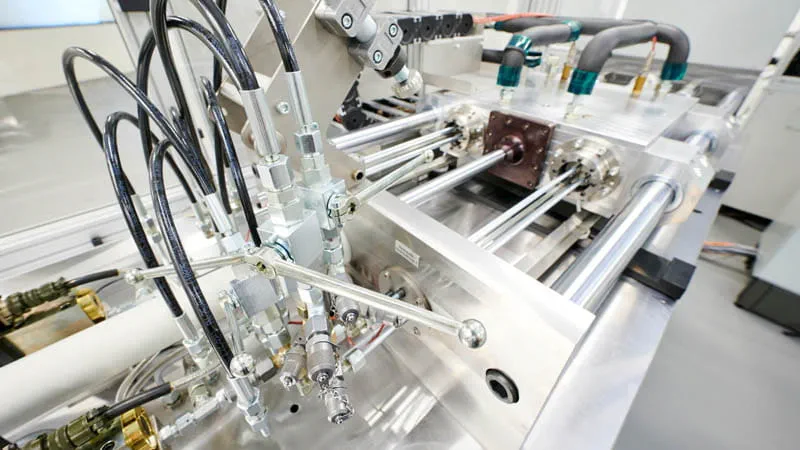

Trelleborg continues to push the boundaries of hydrogen sealing validation by creating proprietary test programs to prove the performance of the H2ProTM range. Leveraging our industry leading R&D capabilities, we use existing and enhanced versions of accepted standards, adapted to real-world hydrogen application conditions in advanced testing rigs.

H2ProTM materials are tested for:

- Oxygen Aging (according to ASTM D572 or ISO 188)

- Ozone Aging (according to ISO 1431-1)

- Hydrogen Compatibility and Rapid Gas Decompression (RGD) (based on a proprietary version of a ISO 17268)

- Permeation (based on ISO 2782-1)

- Endurance Validation (based on a proprietary version of ISO 19880-3, UN ECE R134, EC79, ISO 12619-2, CSA ANSI HGV 3.1, ISO 17268 & SAE J2600)