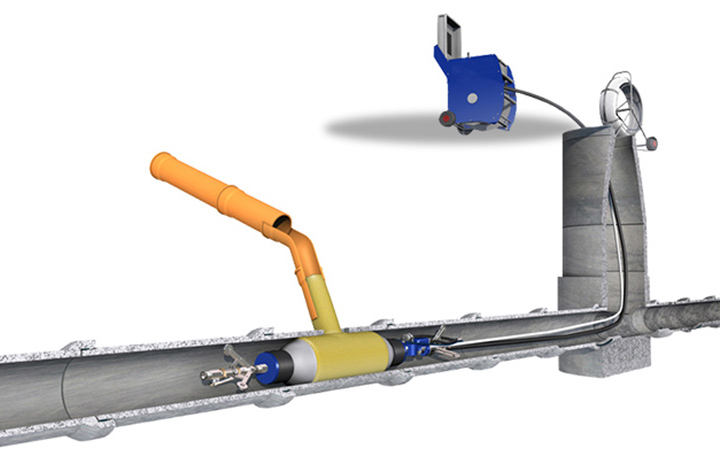

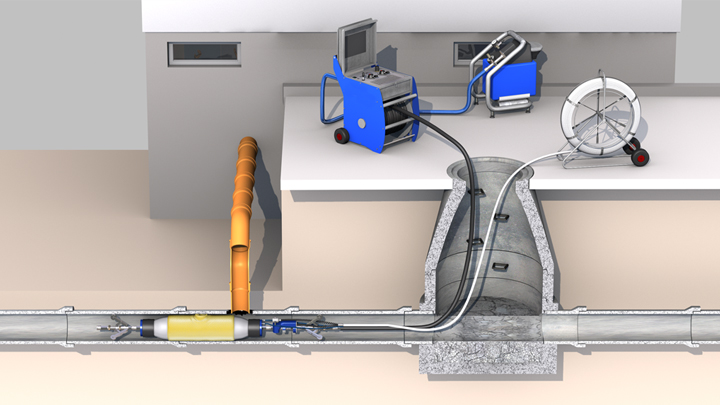

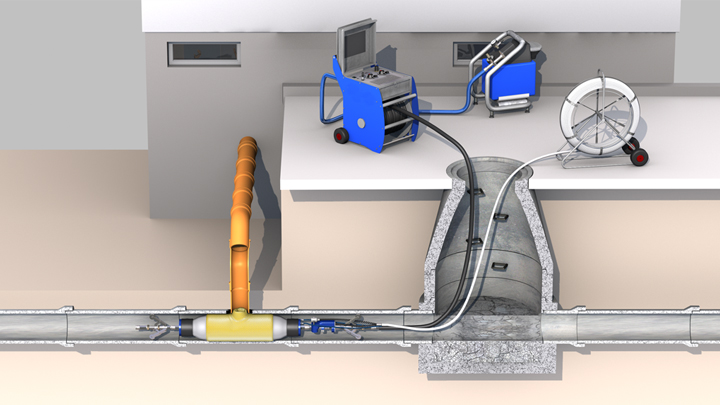

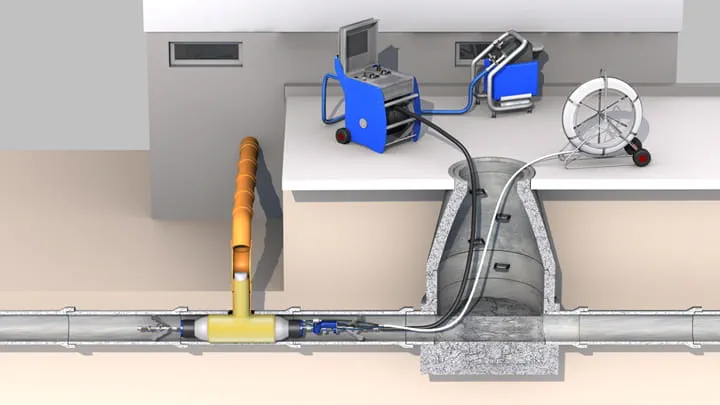

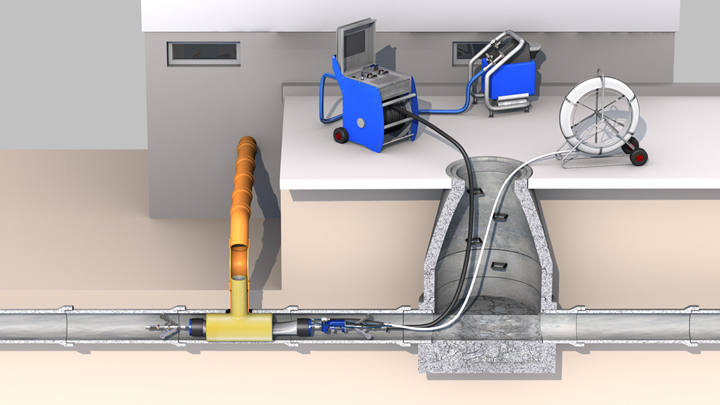

The Trelleborg LCR-S method

The Trelleborg LCR-S system is an essential method and cost-saving tool to repair and permanently seal main/lateral interfaces and connections from the main line (DN 135 - DN 600) down into the lateral (DN 100 - DN 200)

Application Areas

Training in Theory and Practice

Certificates

Watertight solutions that last

Trenchless. Stressless. Tight