Sealing Solutions for Hydrogen

Our facility allows us to create tailored test procedures and evaluate hydrogen seals for critical performance factory, including:

- Hydrogen leakage

- Material compatibility

- Dynamic performance

- Permeation resistance

Innovative Sealing Solutions for Hydrogen

Learn more about industry solutions for the complete hydrogen value chain.

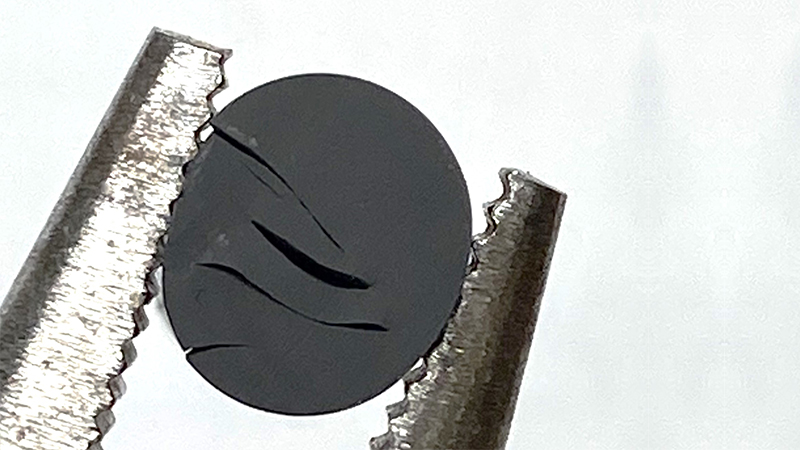

Rapid Gas Decompression (RGD) and Thermal Testing

Our experts conduct detailed analyses of critical conditions, such as Rapid Gas Decompression (RGD). In high-pressure hydrogen systems, sealing materials can absorb gas and if the pressure decreases suddenly, the trapped gas expands, which can cause seals to bubble or tear.

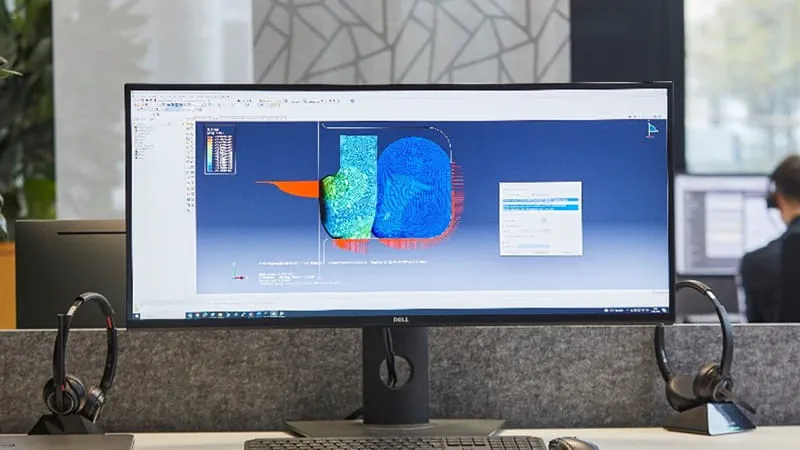

In our advanced test facility, we simulate extreme conditions to ensure our materials perform reliably. We conduct tests at pressures up to 103.4 MPa/14,996 psi and across a wide temperature range, from cryogenic (-196 °C/-320 °F) to +180 °C/+356 °F. We also perform thermal cycle tests under various pressure profiles to ensure durability and safety in demanding hydrogen environments.

In our advanced test facility, we simulate extreme conditions to ensure our materials perform reliably. We conduct tests at pressures up to 103.4 MPa/14,996 psi and across a wide temperature range, from cryogenic (-196 °C/-320 °F) to +180 °C/+356 °F. We also perform thermal cycle tests under various pressure profiles to ensure durability and safety in demanding hydrogen environments.