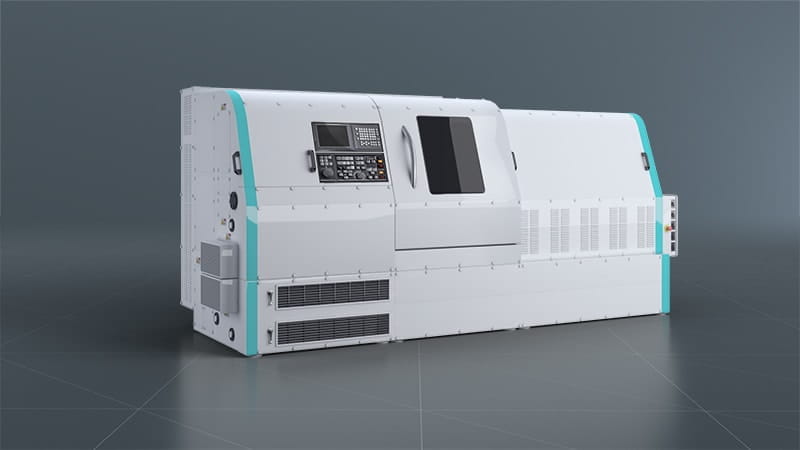

Sealing Solutions for CNC Machines

Computerized Numerical Control (CNC) machines have complex systems that enable machining tasks to be fully automated. Pre-programmed software controls both linear and rotary machine and tool movement, allowing for multi-faceted designs.

Typical operations that can be performed by a CNC machine include milling, grinding, cutting, punching, and lathing in which there is rotation of the work piece, tool or both components.

Given the range of possible movements, a variety of seals play a vital role in ensuring the precision of these machines with each being matched to a function to provide the best in performance and up-time. Sealing configurations need to stand up to high rotational forces and constant running, as well as reciprocating and oscillating movements, while keeping lubrication in the system and preventing ingress of contaminants.

Contact us for support with your CNC machine application

Recommended sealing solutions:

- Zurcon® Roto Glyd Ring® S provides a low friction seal that ensures the oscillating movements, commonly seen on the rotary table and swivels, run smoothly.

- Turcon® Varilip® PDR and Turcon® HiSpin PDR RT seal effectively in high speed, continuously operating rotary environments, while reducing required assembly space on high-speed machining heads.

- V-Rings® fit directly into the shaft and seal axially against a counter surface. They have a light lip pressure to generate low friction while keeping dust and other particles out of the system.

- Rod & piston seals prevent leakage while providing low-friction with no stick slip, allowing the precise positioning required for machine tools. Turcon® Glyd Ring® are ideal for this application, with certain material grades suitable for pneumatic systems as well.

- Wear Rings guide the piston and piston rod within the hydraulic cylinder, absorbing transverse forces and preventing metal-to-metal contact.

- Static seals and scrapers prevent environmental contamination from entering sensitive components. Ingress is particularly aggressive in CNC machines due to the particles generated by machining and the fluids used for cooling. Turcon® Excluder 2 or 5 is an ideal solution.

Application examples

- Rotary Indexing Table

- Revolving Distributors

- Clamping Systems

- Swivel Motors

- Tool Revolvers

- Turrets

- Milling Heads

- Processing Machines

- Drilling Heads

- Motor Spindles