Installation & assembly services

Trelleborg Sealing Solutions Aerospace will work to develop installation methods and tools to support the integration and installation of our products into your application, ensuring the highest product integrity and performance.

Trouble shooting

Trelleborg Sealing Solutions Aerospace uses a systematic approach to problem solving, to find and correct issues with complex applications using resources such as Finite Element Analysis (FEA), Design Failure Mode Effect Analysis (DFMEA) and Process Failure Mode Effect Analysis (PFMEA). This gives the customer the necessary support to identify root cause or causes.

Testing & qualification

Trelleborg Sealing Solutions Aerospace offers the most comprehensive research, development and test facilities. Our aerospace team conducts fire testing and fire resistance testing to the following standards and specifications: AC20-135 and ISO 2685.

Reverse engineering

Trelleborg Sealing Solutions Aerospace can offer the reproduction of a product following detailed, statistical examination of its construction and composition.

Material identification & Analysis

We take a systematic approach to identify each particular element of a specified material.

Design & Development

Trelleborg Sealing Solutions Aerospace members are highly skilled at assisting in the initial phases of design to meet your specification which ensures the highest product performance for a given application. Cost reduction initiatives Trelleborg Sealing Solutions Aerospace is eager to use our worldwide experience to conduct analysis of your operations and offer areas of improvement to realize reduced costs and higher efficiencies.

Product improvement

Our aerospace team are experts in the process of making meaningful product changes that result in increased benefits to our existing customers. Recognizing product design improvements, new customers are regularly added to our portfolio base.

Specialized packaging

Our aerospace team offers complete customized packaging solutions defined by your specific requirements. Optimal packaging of your products ensures protection while in transit as well as ease of storage upon arrival at your facility.

Kitting

Trelleborg Sealing Solutions Aerospace can easily manage consolidation of multiple components under a kit master part number while maintaining full traceability of each individual part ensuring quality control for our customers.

Sub-assembled components

Trelleborg Sealing Solutions Aerospace can develop sub-assemblies (units assembled separately but designed to be incorporated with other units into a larger manufactured product) that integrate multiple sealing elements which will provide overall cost savings and efficiency into the assembly process.

Component reduction

We can supply integrated products that eliminate multiple complex and costly components. This solution results in less overall component count while improving cost and overall performance for our customers.

Measurement services

Trelleborg Sealing Solutions Aerospace offers a broad array of measurements services for parts and application hardware including surface finish and Coordinate-Measuring Machine (CMM).

Project management

Trelleborg Sealing Solutions Aerospace offers comprehensive project management services to organize, prioritize and manage resources through all phases of your project ensuring success in a timely and comprehensive fashion.

Inventory management

Trelleborg Sealing Solutions Aerospace excels at providing a process to manage the flow of polymer parts from Trelleborg Sealing Solutions into the customer’s warehouse, relieving the customer of this burdensome task. Our quality and delivery programs eliminate the duplication of receiving and inspection of inventory for our customers.

Direct Line Feed (DLF)

Utilizing DLF, Trelleborg Sealing Solutions Aerospace can seamlessly manage the flow of parts from Trelleborg Sealing Solutions into the production line and point of use for our customers. One option to realize this is to take advantage of our kitting programs featuring specialized packaging.

Electronic Data Interchange (EDI)

EDI is the structured, electronic transmission of business transactions, such as purchase orders and invoices, between computer systems. Trelleborg Sealing Solutions Aerospace offers EDI exchange with anticipation of increased efficiency, elimination of manual errors along with Just-in-Time manufacturing which will ensure our products arrive complete and on-time for our customers.

Kanban

Trelleborg Sealing Solutions Aerospace utilizes a scheduling system that promotes lean processes and Just-In-Time inventory replenishment programs to help companies improve their production and reduce their overall inventory.

|

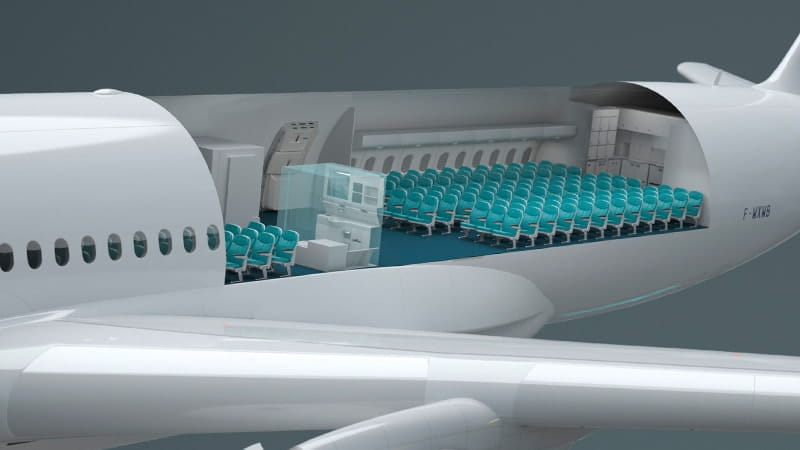

ATA 25 Equipment/Furnishings ATA 26 Fire Protection ATA 27 Flight Controls ATA 28 Fuel ATA 29 Hydraulic Power ATA 32 Landing Gear ATA 35 Oxygen ATA 36 Pneumatic ATA 38 Water/Waste ATA 50 Cargo & Accessory Compartments ATA 52 Doors |

ATA 54 Nacelles/Pylons ATA 57 Wings ATA 71 Power Plant ATA 72 Engine Turbine/Turbo Prop Ducted Fan/ Unducted Fan ATA 73 Engine & Fuel Control ATA 74 Ignition ATA 75 Air ATA 76 Engine Controls ATA 78 Exhaust ATA 79 Oil ATA 83 Accessory Gear-Boxes |