When three became one: an innovation that’s the real deal for seals

Trelleborg is constantly working to push the limits of what’s possible. One of our innovation team’s latest inventions comes in response to customers’ frustrations with the options available for sill sealing. The ModularEase seal is a ‘three-in-one’ solution that can make sealing easier for the construction sector and unlock significant cost savings for end users.

The construction market has seen a strong shift toward prefabricated buildings in recent years. This trend is particularly strong in the Nordic countries, but is a widespread phenomenon driven in no small part by environmental reasons. Wooden buildings have been a common choice for one- or two-family houses or smaller hotels with between one and four floors. However, with restrictions on the number of stories increasingly being lifted in many parts of the world, commercial real estate developers have also been exploring the use of modular timber construction for high-rise buildings.

Padding problems pile up

Sealing plays a small but critical role in wooden constructions, which just as other buildings, face a wide range of requirements for stability, tightness, and protection. It is not enough to simply protect against humidity, wind, rain, heat, and cold: wooden buildings also need to dampen sound to prevent noise pollution. Sound dampening is especially important in commercial properties, such as hotels, retirement homes, and multi-residence housing units.

The prevailing solution for multi-story timber buildings is to use precut polyurethane (PUR) pads, but this option has certain drawbacks. PUR pads are usually precut for different loads, and each one must be individually positioned on the contact points between the walls and ceilings – a time-consuming manual process. Furthermore, this process still requires the use of an additional seal: one component seals the building while another provides the sound-dampening effect.

Moreover, choosing the right PUR pad is not always straightforward. The market offers end users multiple options, all with different static ranges, and the right solution must be selected based on the building’s load. Selecting the wrong pad or using the wrong volume adds time and expense. The variation of pads also brings high inventory requirements for companies, adding to their costs and having a knock-on effect on their working capital.

Working with customers

Trelleborg was uniquely placed to find a new way to solve these problems. We apply a cross-company approach whereby our engineers and innovation experts work closely with our sales team to understand our customers and the challenges they are facing. Through frequent conversations, it was clear many customers were frustrated with the market’s limited range of sealing solutions.

“When it comes to developing new solutions, the whole team is involved, including the customers,” explains Per Anqvist, Innovation Projects Manager Profiles at Trelleborg Sealing Profiles. “The feedback from the market was that PUR seals were inefficient and expensive, so we decided to do something about it and add value.”

Per led a brainstorming session alongside a team of Trelleborg engineers, known as the Innovation Team. Their solution was to develop a more streamlined system that would be easier to install and would include both a sealing and sound-dampening component.

Trial and success

With a clear objective in mind, the Innovation Trelleborg team developed a prototype and began testing it under real-world conditions. After passing earlier internal evaluations, the new prototype was submitted for more rigorous testing at the Holzforschung Austria (HFA) institute, a leading research center for the timber industry located in Vienna. The early results were positive. “The solution looked extremely promising,” says Anqvist. “So, we started to find ways to fine-tune it, and look at what materials we could add to improve it.”

Trelleborg’s philosophy is to experiment by combining new materials to create synergies between their different material qualities. In the case of the ModularEase solution, the Sealing Profiles team combined two polymers with different levels hardness to enable sound absorption across a range of different frequencies. The materials included ethylene propylene diene monomer (EPDM), which is also more fire-resistant than PUR.

A modular sealing system

Following various stages of development, Trelleborg can offer customers the ModularEase, a modular sealing system with a similar sound dampening effect to the PUR seals. However, Trelleborg’s product also enables load bearing and sealing: a true ‘three-in-one’ solution that means the user no longer needs to insert additional sealing between layers during construction.

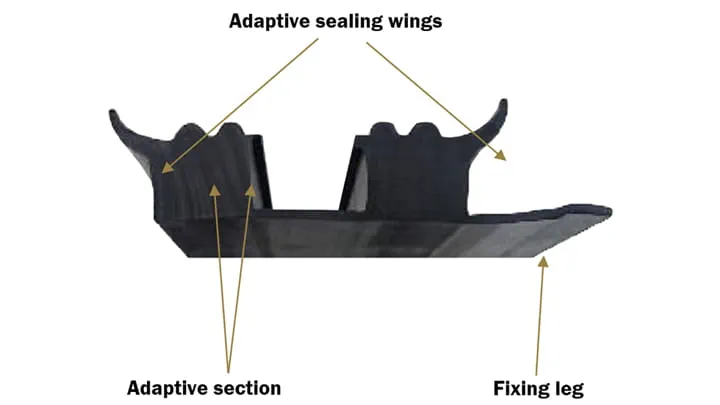

Rather than having to be put into position individually like traditional PUR seals, the ModularEase solution is offered in a meter-long coil that can be rolled out and stapled to the wooden walls. At the same time, sealing ‘wings’ included in the design provide automatic sealing, and an adaptive section means it can be used on irregular surfaces.

As opposed to making the right selection from a wide range of varieties like the PUR pads, the ModularEase comes in just two variants. This not only means it easier for end users to select the product they truly need, but also eases companies’ inventory needs. Furthermore, because this system provides both sealing and dampening, it does not require extra material to seal the gaps and is easy to stable through the fixing leg.

As well as enabling easier installation, Trelleborg’s single-sheet solution can carry a heavier load, thanks to an extra profile placed in the middle of the seal. One product can carry the load of up to four floors, but Anqvist says his goal for the seal is to eventually cover eight floors. This also helps ensure the load distribution is spread evenly over the full length of the supporting wall, providing a high degree of structural stability. While it can be difficult to gauge the maximum load of PUR seals, this is more clearly defined with the ModularEase solution.

With a need for high-quality solutions at efficient prices, the construction industry is changing fast, and the components involved must be adapted accordingly. While Trelleborg’s ModularEase has been designed to respond to customers’ existing pain points, the best may be yet to come.

For more information about the ModularEase solution, please contact gold.standard@trelleborg.com.