Liner removal using PowerCutter keeps Tokyo flowing

Challenge

Serving more than 37 million people, the megalopolis of Tokyo has one of the largest and most complex public wastewater systems in the world. The network processes approximately 5 million cubic meters of wastewater each day, so when something goes wrong, the race is on to get things flowing again.

With millions of pipes in constant need of repair and replacement, complications are common. One such incident involved the failed installation by a contractor of a cured-in-place pipe (CIPP) liner in a specific section of the system. During the original curing process, the end cap was inadvertently removed during the installation process, resulting in a loss of pressure and temperature. Attempts to secure the liner failed, and project personnel were unable to properly install the liner leading to a defective liner in the pipe. The only solution was to remove the liner and reinstall a new one.

The CIPP liner was steam-cured and made of reinforced glass fiber, specifically manufactured to be corrosion-resistant for an aggressive wastewater environment. With this class of liner, the glass fiber is woven into the fabric. Compared to traditional polyester needle fleece knitted fabric, the liner’s unique make-up strengthens its mechanical properties, allowing it to withstand higher pressure of the waterflow. However, it also makes the liner material more challenging to remove when things go wrong.

Our activities: The right equipment for the job

After the failed installation, several methods were used to remove the liner with little success. Big Valley Service (BVS) was then contracted to provide a quick, effective solution to remove the defective liner, and prevent extended disruption to the network. Adding to the challenge, the Japanese Municipalities enforce strict rules and standards regarding liner dimensions with additional earthquake design requirements, making the country’s liners among the thickest in the world. In this case, the width of the liner section being removed varied significantly, ranging from 300 mm to 600 mm in diameter with a thickness of between 10–15 mm however because of failure installations, the thickness became 15–30mm with corrupted layers.

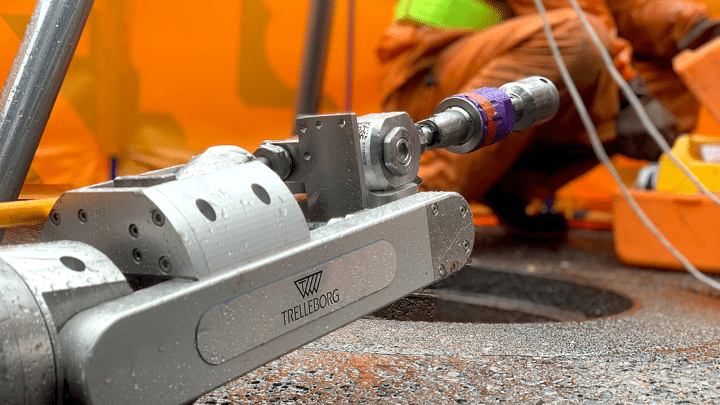

BVS used a combination of milling and high-pressure water-jetting to remove the failed liner. Importantly, the liner needed to be cut into separate pieces to be lifted above ground via existing manholes. The exact length of each section being cut depended on the size of the manhole. In total, the project team needed to account for five different manhole dimensions, with diameters ranging between DN 900 and DN 1,200. Cutting was performed using Trelleborg’s state-of-the-art robotic cutter, PowerCUTTER 200, controlled by an operator above ground via a console, and monitored via CCTV.

The robotic cutting work was performed by a single operator supported by three workers for approximately six days. After robotic cutting of the defective liner from the pipe, the BVS team removed it from the manhole over a further four days in smaller 50cm pieces. The entire process of removing the failed liner was successfully completed in less than 10 days.

After the project Mr. Daizo Shinada, owner of BVS, shared his experience on the project. He was very happy with the performance delivered by PowerCUTTER 200 and commented: “BVS was awarded the works after several contractors unsuccessfully attempted to remove the defective liner. The end customer was extremely satisfied with the speed at which the works were completed. We are pleased to showcase the power of the PC200.”

Solution details: The PowerCUTTER 200

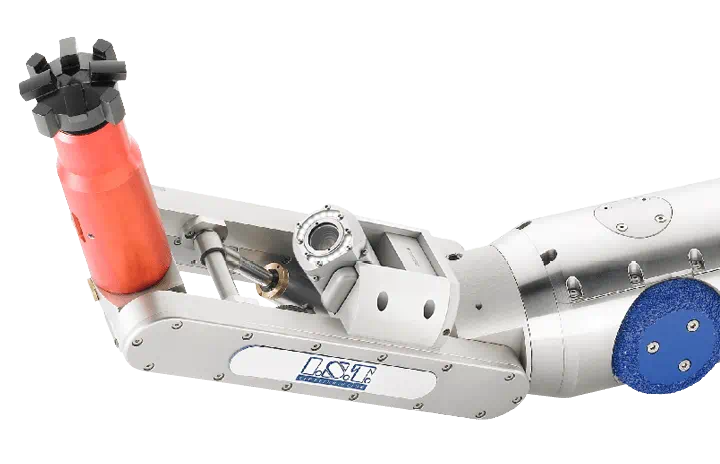

One piece of equipment proved particularly crucial to the success of the project: the PowerCUTTER 200. Manufactured by Trelleborg, it is a multifunctional robot designed to remove difficult obstacles, such as concrete, intruding pipes, deposits, roots and steel in water and wastewater pipes, in order to restore water flow.

The PowerCUTTER 200 is fitted with an accessory that uses high-pressure water-jetting technology – a non-invasive, cost-effective method of quickly removing major sewage deposits (including defective liners) that minimizes damage to the remaining infrastructure. Water is pumped into the PowerCUTTER 200 at ultra-high pressures of up to 2,500 bar. At these pressures, and with the correct nozzles, the water can cut various materials, including concrete, metal and glass-reinforced plastic (CIPP liners). The robotics of the PowerCUTTER 200 allows precision-controlled cutting.

Importantly in this case, the tool offered the versatility to work with various cutting technologies in a wide range of diameters (from DN 200 to DN 600). The cutter incorporates the benefits of forward and back cameras, zoom features, LED lighting, an assortment of packer and bladder add-ons for pipe repair various pipe repair systems, and the option of a high-pressure water-jetting nozzle, fixed to the cutter as an add-on.

This functionality was critical to the complex nature of the project, and the need for a swift, effective, non-invasive solution.

attempted to remove the defective liner. The end customer was extremely

satisfied with the speed at which the works were completed. We are pleased to showcase the power of the PC200"

For more information contact: