Ever Wondered What Stops an Excavator? It Might Be Just a Seal

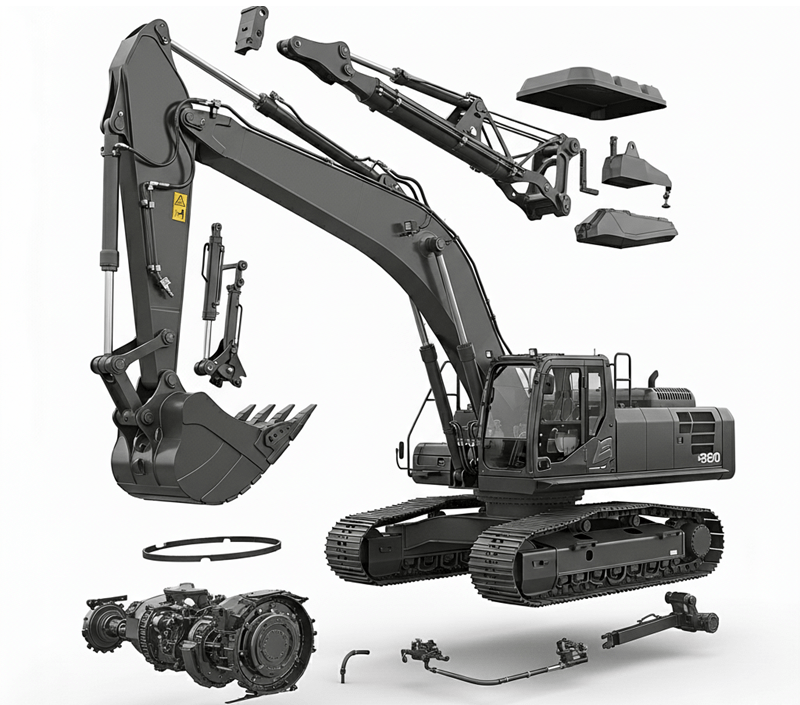

Excavators and other construction equipment operate in some of the most demanding environments: rocky hills, deep tunnels, dusty plains, and rugged construction zones. These machines are critical to building the infrastructure that powers progress — especially in countries like India, where large-scale projects are transforming the landscape.

The Backbone of Infrastructure Development

In India, the construction equipment industry is witnessing rapid growth, driven by government-led infrastructure initiatives, urbanization, and increased mechanization in construction and mining. Excavators, in particular, are at the heart of this transformation.

However, despite large-scale project allocations — especially for roads and public connectivity — delays are common. Land acquisition hurdles, contractor issues, and approval bottlenecks often slow progress. And once a project enters the execution phase, even a single machine breakdown can result in significant loss of man-hours and money.

So, What Causes an Excavator to Break Down?

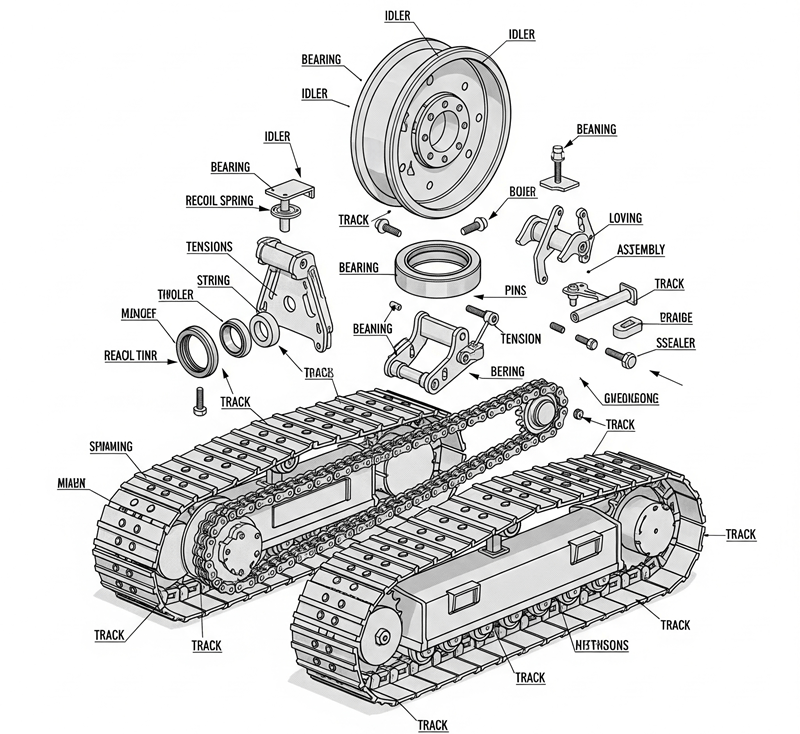

At first glance, an excavator looks like a rugged, indestructible machine — and it mostly is. But just like any complex system, it relies on a network of precision-engineered components. One such critical (but often overlooked) part is the idler in the track roller system.

In tracked construction equipment, an idler is a wheel that guides and supports the track chain. Unlike a drive sprocket, it doesn’t transmit power but plays a vital role in:

- Maintaining proper track tension and alignment

- Guiding the track smoothly around the undercarriage

- Absorbing shocks and reducing wear, increasing longevity

- Improved efficiency and fuel economy

- Safety and operational stability

- Managing maintenance costs

If the idler is down, the entire track can derail and stop any further movement in the field.

One of the components that supports the idler to stay intact and continue working is the sealing used. The seal in an excavator's idler prevents abrasive contaminants like dirt and debris from entering the idler bearing and maintains lubricant (gear oil) inside, allowing the idler to rotate smoothly and preventing wear and premature failure of the idler assembly. A failed seal in the idler is a serious issue that can lead to premature idler failure and even damage other parts of the undercarriage if not addressed quickly. A failed idler seal might look like a small problem, but it snowballs fast, leading to bearing/ bush failure, contaminant ingress, heat buildup, and eventual mechanical breakdown of the undercarriage — costing time and money.

One of India’s leading excavator manufacturers was looking for a localization for one of the idler seals. The existing sealing solution was imported and came with limited technical and service support, leaving the manufacturer with inadequate assistance. Operating in harsh conditions—exposed to dust, open environments, and occasional moisture—the application demanded a reliable, “fit-and-forget” sealing solution that offered long service life and easy installation.

When the customer approached Trelleborg, we responded with a tailored solution supported by local manufacturing and engineering expertise. Our engineers met all their requirements, recommending a mechanical face seal as a part of a comprehensive package. This included localized production with globally benchmarked quality, on-demand technical support at both local and global levels, and a flexible MOQ-to-schedule model. Our approach enabled lean inventory management and just-in-time supply, ensuring immediate availability while reducing on-hand inventory.

Customer benefits:

The customer gained seamless access to the supplier and their support, significant savings in both direct and indirect costs, and enhanced operational efficiency through scheduled deliveries, and benefited from local technical expertise with improved responsiveness.

Mechanical face seals for idler cushion assemblies are heavy-duty sealing solutions designed to protect internal components from abrasive dust, mud, and water in harsh operating environments. Typically made of two robust metal rings with rubber elements, they are a “fit-and-forget” component built for long service life and easy assembly. Link

Mechanical face seals or heavy-duty seals are specifically engineered for rotating applications in extremely arduous environments where they withstand severe wear and prevent ingress of harsh and abrasive external media. A Mechanical Face Seal is also known as heavy duty seal, face seal, lifetime seal, floating seal, duo cone seal or toric seal.

Types of Mechanical face seal

There are two different types of mechanical face seals / heavy duty seals:

- Type DO is the most common form that uses an O-Ring as a secondary sealing element

- Type DF has an elastomer with a diamond-shaped cross section as a secondary sealing element instead of the O-Ring

Both types consist of two identical metal seal rings mounted in two separate housings face-to-face on a lapped seal face. The metal rings are centered within their housings by an elastomer element. One half of the mechanical face seal remains static in the housing, while the other half rotates with its counter face.

Features And Benefits

- Simple, reliable design

- High sealing against dirt, dust, water and abrasive media from the outside and against oil and grease from the inside

- Long service life

- Floating, useful against vibration or misalignment

- Maintenance-free

- Easy to assemble

Applications:

Market segments as: Agriculture, mining, construction, industrial

Applications such as: Gearboxes, axles, undercarriages, tunnel boring machines, conveyor systems, mixers, stirrers and other applications with similar conditions or where maintenance-free lifetime sealing is expected.

Find out about Trelleborg Sealing Solutions Bangalore Plant's manufacturing capabilities & schedule a call with a technical expert to discuss your requirements.