Hydrogen is key to achieving sustainable development policies, which aim to reduce greenhouse gas emissions. Once generated, hydrogen can be stored and transported to places where energy consumption is high and energy from renewable sources is not sufficient.

Hydrogen storage technologies require effective sealing solutions to ensure the safe containment and efficient utilization of this versatile gas. The unique properties of hydrogen, such as its low molecular size and high diffusivity, present significant challenges for sealing technologies. Advanced seal materials and designs are employed to withstand extreme pressures, temperature differentials, and hydrogen permeation. High-performance sealing solutions support the facilitate the widespread adoption of hydrogen as a clean energy source, promoting a sustainable future.

H2Pro™ Materials

Our H2Pro™ range is a family of specially engineered materials, designed to meet the unique needs of hydrogen applications.

Hydrogen Storage Applications

Hydrogen Compressor

Compressors require high performance sealing solutions to protect hardware and prevent leakage, which can operate at speeds up to 4 m/s or 13 ft/s, a wide temperature range, from -40 °C to +200 °C/-40 °F to +392 °F, and very high pressures, up to 1000 bar/14,504 psi.

Products

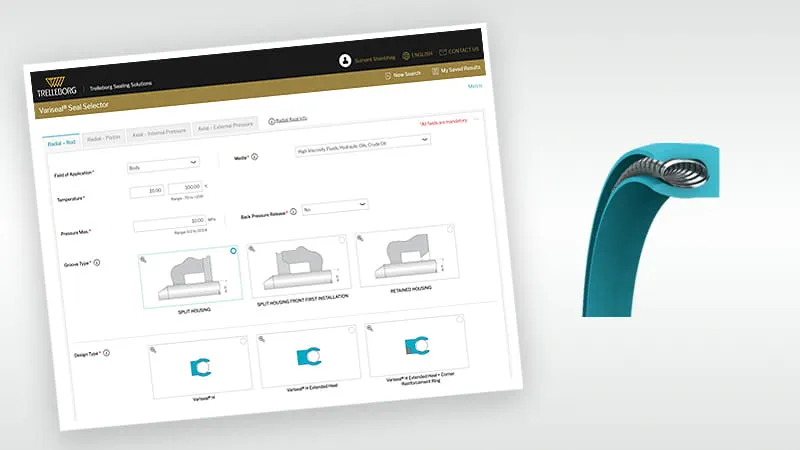

- Hydraulic rod and piston seals, e.g. Turcon® Variseal® M2 and Turcon® Variseal® W2

- Specially designed piston ring systems

- Advanced thermoplastic solutions

Compressed Hydrogen Gas (CGH2 ) Storage & Transport

Sealing solutions for hydrogen storage and transportation must be suitable or use at low temperatures and high pressures, while minimizing the sealing gap and resisting permeation. CGH2 is stored and transported at -50 °C-+85 °C/-58 °F-+185 °F with high pressures up to 105 MPa/15,229 psi.

Products

- H2Pro™ elastomer materials for low temperature applications

Liquid Hydrogen (LH2) Storage & Transport

Stored at cryogenic conditions, elastomer materials are not suitable sealing materials for liquid hydrogen applications. Our family of metal and plastic seals is suitable for sealing in extremely low temperature environments.

Products

Low Pressure Valves

Low pressure valves are commonly used between electrolysis and compression. These valves function at pressure below 100 bar/1,450 psi. The expansion behavior of hydrogen leads to rising temperatures in the application and seals must function at temperatures between -40 °C and +150 °C/-40 °F and +302 °F.

Products

- O-Rings

- Engineered molded parts

- Valve tappet seals

High Pressure Valves

At filling stations and compressors, high pressure valves control the flow of hydrogen into and out of the tanks. LH2 is stored at cryogenic conditions and CGH2 at extreme high pressures, making high performance sealing solutions crucial. Seals in high pressure valves must withstand pressures up to 1,000 bar/14,504 psi and a wide range of temperatures, -50 °C-+85 °C/-58 °F-+185 °F.

Products

Connector

Connections are everywhere in the hydrogen supply chain and reliable sealing is vital to maintain efficiency and reliability whether liquid, or gaseous hydrogen is being transported. Seals must be able to operate under high and low pressures and low and very low temperatures.

Products

- O-Rings and O-Ring with Back-up Ring for high pressure

- XploR™ S-Seal

- Turcon® Variseal® H and Turcon® Variseal® HF

- Wills Rings® metal seals