FlatSeal™ HMF10 series is a group of elastomer-bonded flat gasket materials composed of high-quality aramid fibers and special functional fillers. They are suitable for use in a wide range of conventional applications. Each material compound has its own unique performance portfolio, making it ideal for use in specific applications.

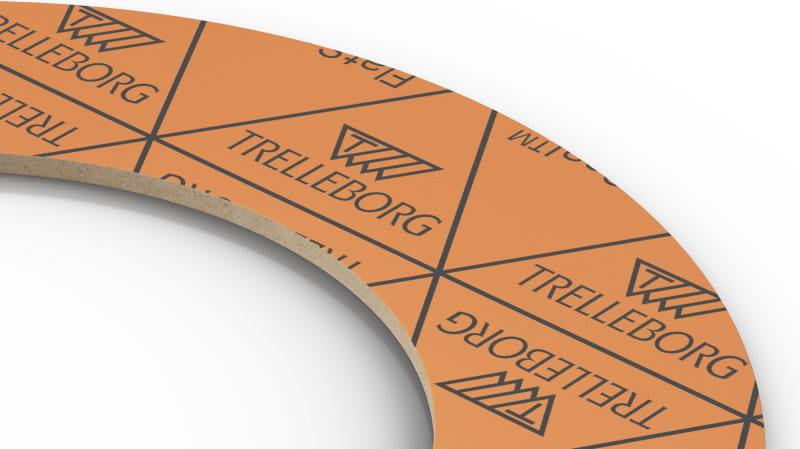

FlatSeal™ HMF10 - Versatile flat gasket for a wide range of applications

Suitable for a broad variety of standard applications, FlatSeal™ HMF10 is ideal for use in operating environments with moderate temperatures and pressures.

FlatSeal™ HMF10 is an excellent standard material for use in moderate pressure and temperature ranges. Its unique composition gives the material special properties:

- Good media resistance

- Excellent residual stress characteristics

- Low gas leakage

For decades, FlatSeal™ HMF10 has proven itself effective in mechanical engineering, plant engineering and shipbuilding applications, as well as in pipeworks for gas and water supply.

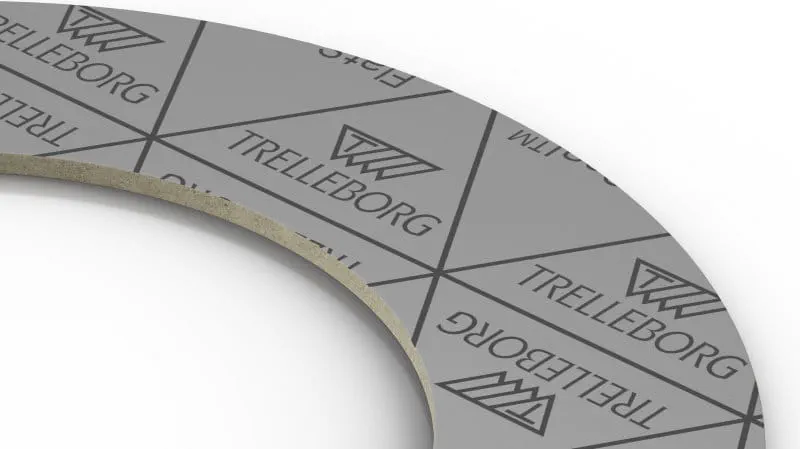

Demonstrating extremely high mechanical strength, FlatSeal™ HMF15 is suitable for use with a wide range of media.Manufactured using a unique processing technology, FlatSeal™ HMF15 incorporates a high proportion of glass fibers into the material compound.

This unique material composition gives FlatSeal™ HMF15 special properties:

- Outstanding mechanical strength

- Excellent hot creep behavior

- Wide ranging media compatibility

FlatSeal™ HMF17 bridges the gap between traditional fiber gaskets and rubber gaskets. This completely new material composition combines the flexibility and tight fit of an elastomer with the robust strength and mechanical stability of a fiber material. The material’s innovative mix of high-quality aramid fibers, special functional fillers, and Nitrile Butadiene Rubber (NBR) provides a unique performance profile.

Features and benefits:

- Excellent adaptability to unevenness at minimum surface pressure levels and during installation

- Extremely low leakage levels even when surface pressure is very low

- Mechanical stability

- Stable long-term properties at moderate operating temperatures

- Good resistance to media and aging

- Smooth processability and safe handling even with complex gasket outlines

- Full traceability of gaskets with FlatSeal™ Code Technology

- Approvals: DVGW, HTB DIN 30653, KTW and WRAS

FlatSeal™ HMF18 - High performance fiber gasket for chemical and industrial applications

Outperforming classic fiber gaskets, FlatSeal™ HMF18 offers a new level of surface adaptability. It is produced using an innovative blend of high-quality aramid fibers, special functional fillers, and Nitrile Butadiene Rubber (NBR) to effectively seal uneven surfaces and provide outstanding leak tightness.

Thanks to its optimized material composition and advanced processing technology, the HMF18 compound demonstrates media resistance and mechanical stability under temperature stress. It is also equipped with FlatSeal™ Code Technology, a permanent fingerprint that enables full traceability from the material batch through to the cut gasket.

Features and benefits:

- 3x higher adaptability to flange unevenness compared to classic fiber gaskets

- Significantly higher tolerance to installation errors

- Mechanical stability

- Excellent leakage performance even at relatively low surface pressure levels

- Minimized maintenance due to more efficient sealing properties

- Extremely low emissions

- Smooth processability and safe handling even with complex gasket outlines

- Full traceability with FlatSeal™ Code Technology

- Meets TA Luft (Technical Instructions on Air Quality Control) requirements, even with manual installation

- Suitable for designs that must comply with VDI (Verein Deutscher Ingenieure, Association of German Engineers) Directive 2290

- Approvals: DVGW, HTB DIN 30653, KTW and WRAS